47

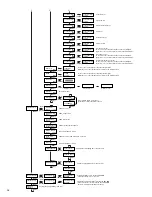

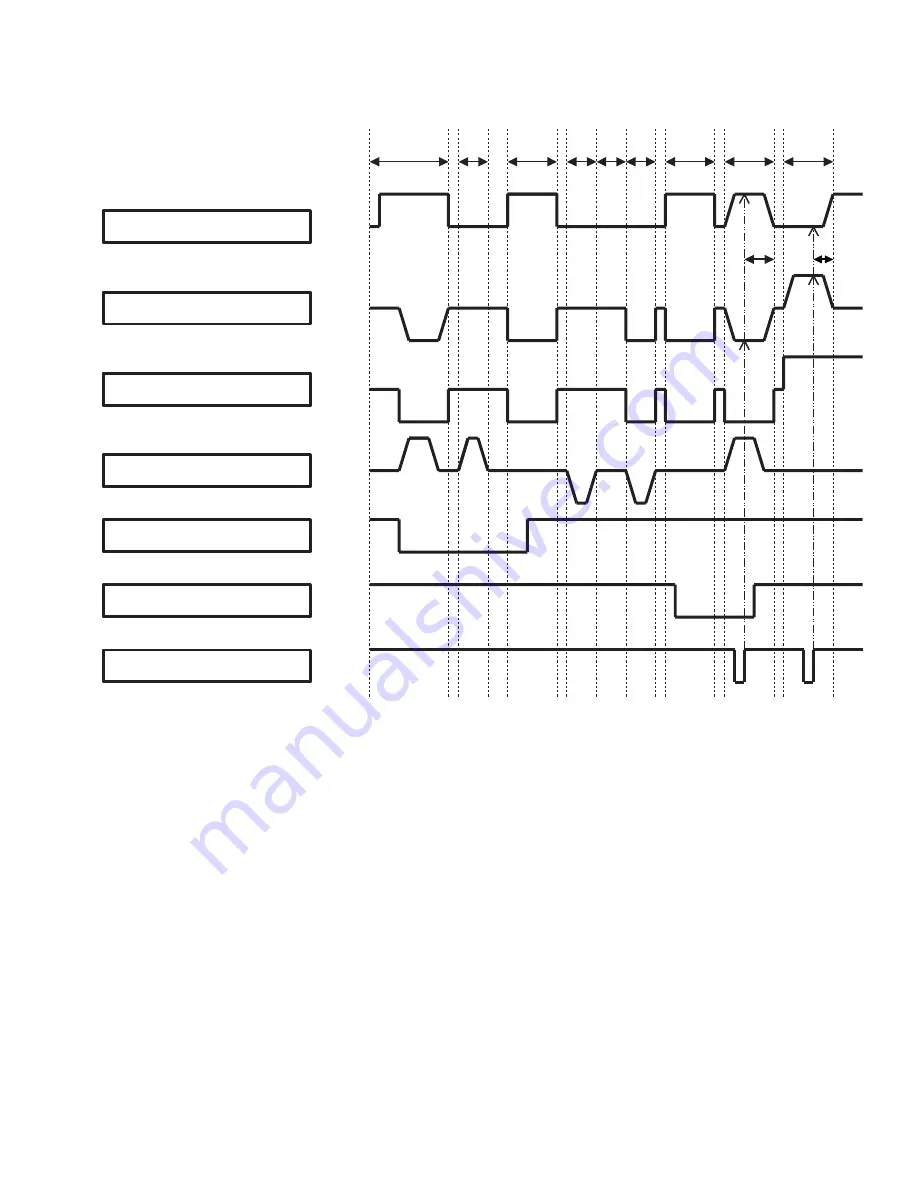

6. Retransfer Operation

OFF

FWD

REV

OFF

CW

CCW

OFF

CW

CCW

Rep

OFF

Fix

Hi

Lo

Hi

Lo

Hi

Lo

N1 N2

1

2

3

4

5

6

7

8

9

Card feed motor

Retransfer film supply motor

Retransfer film take-up motor

Cam motor

Card edge sensor

Card outlet sensor

Retransfer film mark sensor

Period

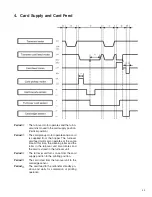

1

: The printed panel on the film and the card

are transported to the retransfer position.

Also, the cam motor operates and the

retransfer roller is moved to the standby po-

sition.

Period

2

: The cam motor operates, the retransfer roller

is lowered, and the film and the card are

pressed against each other.

Period

3

: The card feed motor operates and retransfer

starts.

Period

4

: The cam motor operates and the bend re-

medial roller is moved to the standby posi-

tion.

Period

5

: The user mode has the item “Cooling time

setting”, and during this period, the opera-

tion is stopped for the set time of 1 to 15

seconds.

** There is no card feed roller between the

retransfer roller and the bend remedial

roller. Card movement in this interval is

done sticking to the film.

Period

6

: The film is moved to the peeling start posi-

tion. (At this time, the card is close to directly

under the bend remedial roller.) Also, the cam

motor operates and the bend remedial roller

is pushed down.

Period

7

: Film peeling and card bend remedial are per-

formed.

Period

8

: After the card has been discharged, the cam

returns to the stand-by position.

Also, one screen is taken up looking at the

film mark sensor.

Period

9

: The film is returned for another screen for

the next printing.