52

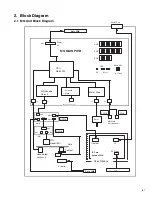

TROUBLESHOOTING

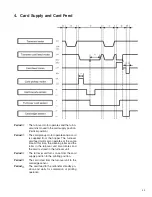

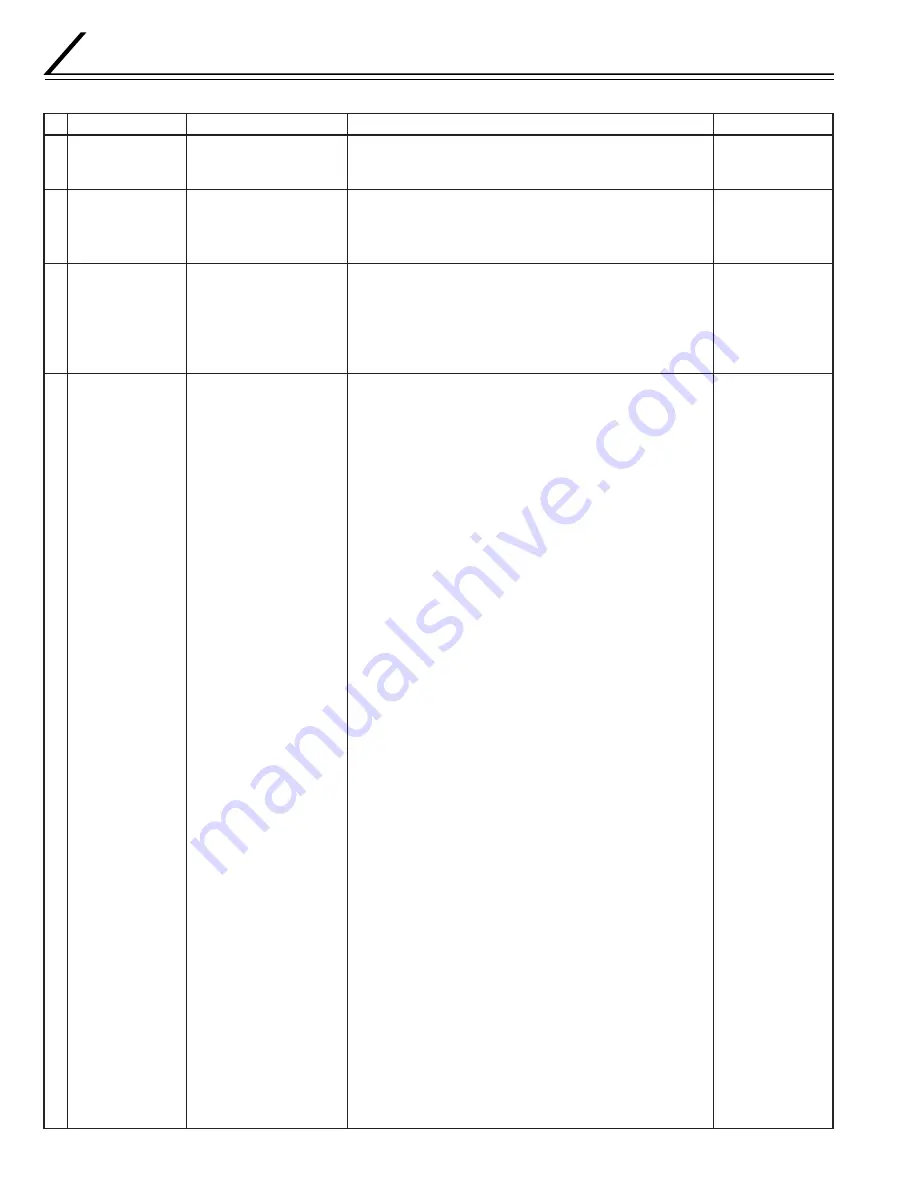

1. LCD Error Code Correspondence

No.

1

2

3

4

Error detection contents

When recovery is not

possible even when the

RESET button is pressed.

When the feed rollers are is

to be cleaned, cleaning mode

is not entered as the transfer

film cassette is present.

In the same way as above,

this message is displayed

when the heat roller

temperature is 50˚C or

more at the time of entry

into cleaning mode.

An error will be caused

when the card supply

sensor is not passed

within a fixed time after

start of card supply.

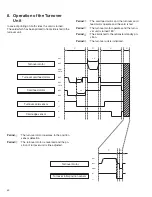

1) Switch off the power and wait for the temperature to

drop.

2) When the retransfer film is in the unit, the heat roller is

heated even in this mode. Always remove the retransfer

film first.

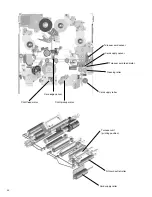

1) Check for sticking of the cards in the card tray because of

static electricity. Try to separate the cards from each other.

Check that the cards are aligned.

2) Is the card push Plate of the card tray in the lock position?

Check the force with which this Plate presses onto the cards. If

it is weak, check for spring elongation etc.

3) In the case of 0.25 mm cards, the number of cards which can

be set in the tray is limited according to the used cards. Test by

trying to set about 50 cards into the tray.

4) Clean the card supply roller with alcohol. Touch the surface to

check if it is slippery.

5) Check the thickness of the thickness adjustment plate and the

card. Also check for correct thickness adjustment in case of

special card thickness (turn the gear of the card supply roller

and check for individual card supply).

6) Perform the diagnostic test in service mode and check for

operation of the card pickup motor. Also confirm correct

operation of intermediate gears.

7) When this message appears at the time of power ON, the

sensor is broken. Use the sensor check of service mode for

confirmation.

8) Check for contamination of the cleaning roller. Clean the roller

if it is dirty.

The life of the cleaning roller is about one year. The adhesive

power gets lost with use for many years.

It is also possible that the roller becomes worn and no longer

can feed the cards correctly.

9) After the cleaning roller, the cards are transported by the

turnover card feed motor.

Perform the diagnostic test of the service mode and check the

operation of the turnover card feed motor.

10)Does the turn over unit come to the card supply position

(vertical position) at the time of card supply? The pulses of the

turnover motor are counted and rotation to the card supply

position is done. When the turnover unit is not pointing straight

down, the card will not enter the rail and an error will be

caused. Perform the diagnostic test in service mode and check

the operation of the turnover unit.

11)Check for correct rotation of the roller in the turnover unit. Clean

the roller in case of rotation. Perform the diagnostic test in service

mode and check the operation of the turnover card feed motor.

Treatment contents

This display appears for example when there is hardware

trouble, as with the following trouble of No. 18-26.

Remove the retransfer film cassette.

This prevents sticking of the cleaning card to the film.

Exchange parts

* Card

* Card supply roller

* Adjustment

* Motor, Drive circuit

board Main circuit

board

* Sensor,

Main circuit board

* Cleaning roller

* Motor, Drive

circuit board,

Main circuit board

* Motor, Drive

circuit board,

Main circuit board

* Motor, Drive

circuit board, Main

circuit board, roller

Error item

Please Power off

Please Remove

Media Cassette

HR is too hot!

Jam (Hopper)

Card jam

(hopper part)