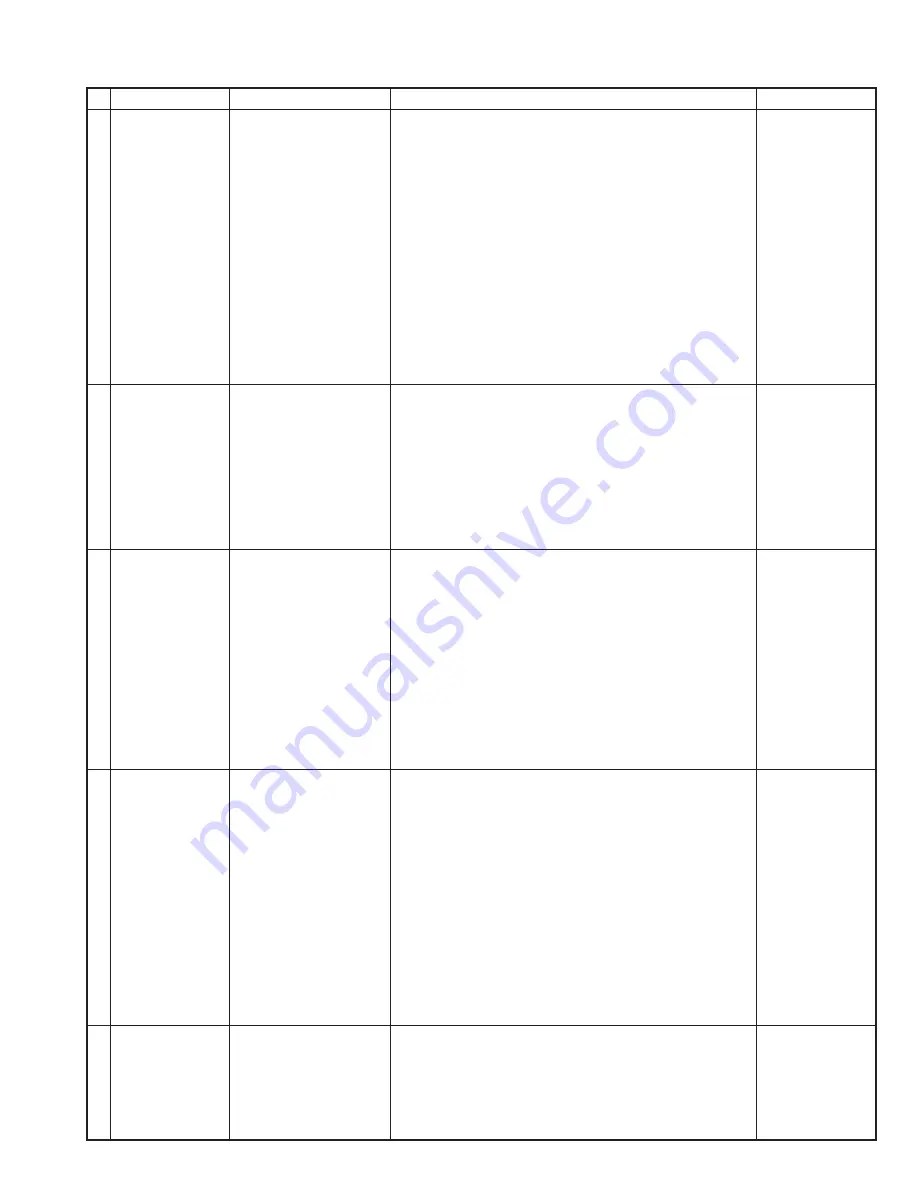

53

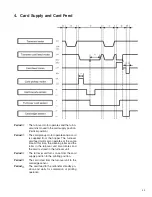

No.

5

6

7

8

9

Error detection contents

When the card does not

enter to or depart from

the sensor inside the

turnover unit within a

specified time.

When the card does not

arrive at the card edge

sensor within a specified

time after leaving the

turnover unit.

Also, in case of magnetic

encoding, when detection

by the start position sensor of

the MG unit is not possible.

When the card outlet

sensor is not reached

within a specified time

after leaving the card

edge sensor.

In case of stopping at

the card outlet sensor.

Detection of the

retransfer motor rotation

condition, pulses,

marks, etc.

Treatment contents

1) When this message appears at the time of power ON,

the sensor is broken. Use the sensor check of service

mode for confirmation.

2) Confirm the operation of the turnover unit until the card

reaches the sensor.

Perform the diagnostic test in service mode and check

the operation of the turnover unit.

3) Check for correct rotation of the roller in the turnover

unit. Clean the roller with alcohol in case of rotation.

Perform the diagnostic test in service mode and check

the operation of the turnover card feed motor.

4) Check that card feed is OK when the turnover unit is

oriented in the print mode direction.

Perform the diagnostic test in service mode and check

the operation of the card feed motor.

1) When this message appears at the time of power ON,

the sensor is broken. Use the sensor check of service

mode for confirmation.

2) Check the operation until the card enters to the sensor.

Perform the diagnostic test in service mode and check

the operation of the card feed motor.

Check belts, gears, and rollers for wear. Clean the

rollers with alcohol.

1) Check if the card sticks to the film.

* If the card sticks to the film, check for correct operation

of the card cooling fan (rotates only at the time of

retransfer).

* If the card sticks to the film, replace the film by a

different film and try printing.

2) Check the condition of the rubber on the retransfer roller

surface.

3) Perform the diagnostic test in service mode and check

the operation of the card feed motor.

Check belts, gears, etc.

1) When this message appears at the time of power ON,

the sensor is broken. Use the sensor check of service

mode for confirmation.

2) Check the condition of the rubber on the bend remedial

roller.

3) Perform the diagnostic test in service mode and check

the operation of the card feed motor.

Check belts, gears, out roller, etc.

4) For bend remedy at the time of one-sided printing, there

is the temperature setting for the bend remedial roller. Is

double-sided printing being done with this temperature

setting too high? In this case, the cards may become

deformed and jams may be caused,

1) Perform the diagnostic test in service mode and check

the operation of the retransfer film supply motor.

2) Perform the diagnostic test in service mode and check

the operation of the retransfer film take-up motor.

Exchange parts

* Sensor, Main

circuit board

* Motor, Drive

circuit

board, Main

circuit board

* Motor, Drive

circuit board, Main

circuit board, roller

* Motor, Drive

circuit board,

Main circuit board

*Sensor x 2,Main

circuit board

MG circuit board

* Motor, drive

circuit board,

Main circuit board

* Belts, gears,

rollers

* Film

* Retrnsfer roller

* Motor, Drive

circuit board,

Main circuit board

* Belts, gears

* Sensor, Drive

circuit board

* Bend remedial

roller

* Motor, Drive

circuit board,

Main circuit board

* Belt, gear, roller

* Motor, Drive

circuit board,

Main circuit board

* Motor, Drive

circuit board,

Main circuit board

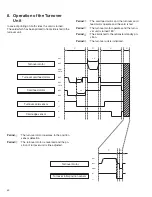

Error item

Jam (TurnOver)

Card jam

(turnover unit)

Jam (MG)

Card jam

(encoder)

Jam (Retransfer)

Card jam

(retransfer

section)

Jam (Discharge)

Card jam

(discharge)

Media Broken

Torn retransfer film

Media Search

Retransfer film

detection error