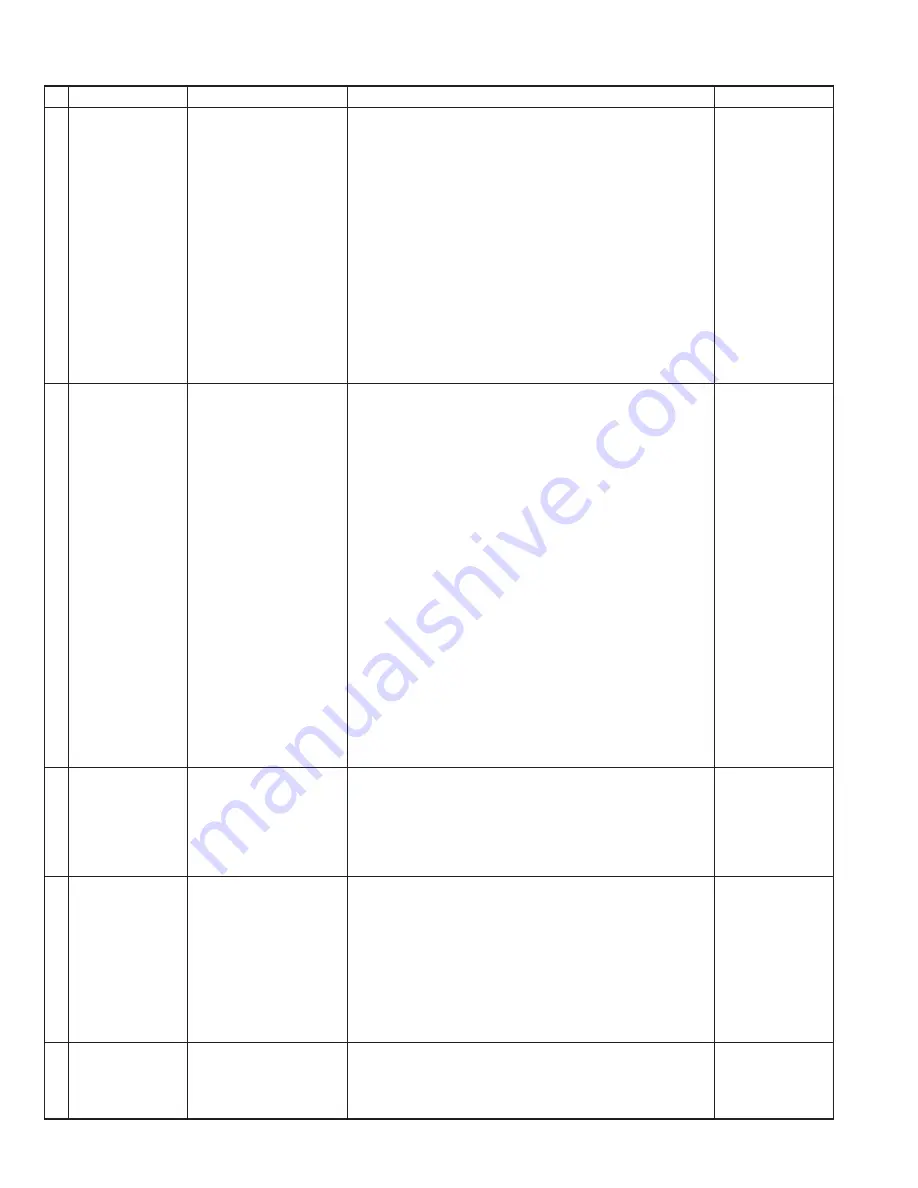

54

No.

10

11

12

13

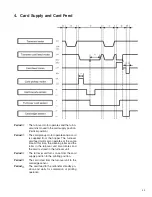

Error detection contents

Detection of ink motor

rotation condition,

pulses, marks, etc.

Detection of the motor

rotation condition and

operation of the

turnover initicl position

sensor.

Detection of the motor

rotation condition and

the cam sensor

operation.

Card presence is

detected by a reflection

sensor.

Treatment contents

3) The retransfer film take-up motor has a encoder for

output of pulses when the motor operates.

Perform the diagnostic test in service mode and check

the output of the encoder of the retransfer film take-up

motor.

4) When this message appears at the time of power ON,

the sensor is broken. Use the sensor check of service

mode for confirmation.

5) Remove the cassette and confirm the retransfer film

installation condition. Confirm that there is no winding

deviation or similar to prevent error of the sensor,

In case of winding deviation, check the shaft, the bobbin

holder, etc. of the retransfer film cassette.

6) If winding eleviation is serious,then replace the

retransfer film with a new one.

1) Perform the diagnostic test in service mode and check

the operation of the ink supply motor.

2) Perform the diagnostic test in service mode and check

the operation of the ink take-up motor.

Perform the diagnostic test in service mode and check

the output of the encoder coupled with the ink take-up

gear.

3) The ink supply motor has a encoder for output of pulses

when the motor operates.Perform the diagnostic test in

service mode and confirm the output of the encoder of

the ink supply motor. (Ink SPY Enc)

4) When this message appears at the time of power ON, the sensor

is broken. Use the sensor check of service mode for

confirmation.

5) Remove the cassette and confirm the ink installation

condition. Confirm that there is no winding deviation or

similar to prevent error of the sensor,

In case of winding deviation, check the shaft, the bobbin

holder, etc. of the ink cassette.

6) If winding eleviation is serious,then replace the ink

ribbon with a new one.

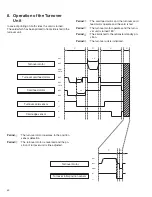

1) Perform the diagnostic test in service mode and confirm

the operation of the turn over motor.

2) When this message appears at the time of power ON,

the sensor is broken. Use the sensor check of service

mode for confirmation.

1) Perform the diagnostic test in service mode and confirm

the cam motor operation.

2) When this message appears at the time of power ON,

the sensor is broken. Use the sensor check of service

mode for confirmation of the cam sensor retransfer roller

sensor, and remedial roller sensor.

3) Check the cam mechanism etc.

4) Check the installation and the wire routing for retransfer

roller and bend remedial roller.

1) When this message appears at the time of power ON,

the sensor is broken. Use the sensor check of service

mode for confirmation of the no card sensor.

Exchange parts

* Motor, Drive

circuit board,

Main circuit board

* Sensor, Main

circuit board

* Retransfer film,

cassette

* Motor, Drive

circuit board,

Main circuit board

* Motor, Drive

circuit board,

Main circuit board,

INK FG circuit

board

* Motor, Drive

circuit board,

Main circuit board

* Sensor, Main

circuit board

* Ink ribbon,

Cassette

* Motor, Drive

circuit board,

Main circuit board

* Sensor, drive

circuit board

* Motor, drive

circuit board,

Main circuit board

* Sensor, drive

circuit board

* Cam

* Roller, wire

* Sensor, Main

circuit board

Error item

Media Run Out

End of the

retransfer film

Ink Broken

Torn ink ribbon

Ink Search

Ink ribbon detection

error

Ink Run Out

End of the ink

ribbon

Turn Over Unit

Defective

operation of the

turn-over

mechanism

Heater Cam

Defective heat

roller operation

No Card

There is no card,

the tray is empty.