59

Printing defect

Cause

Countermeasure

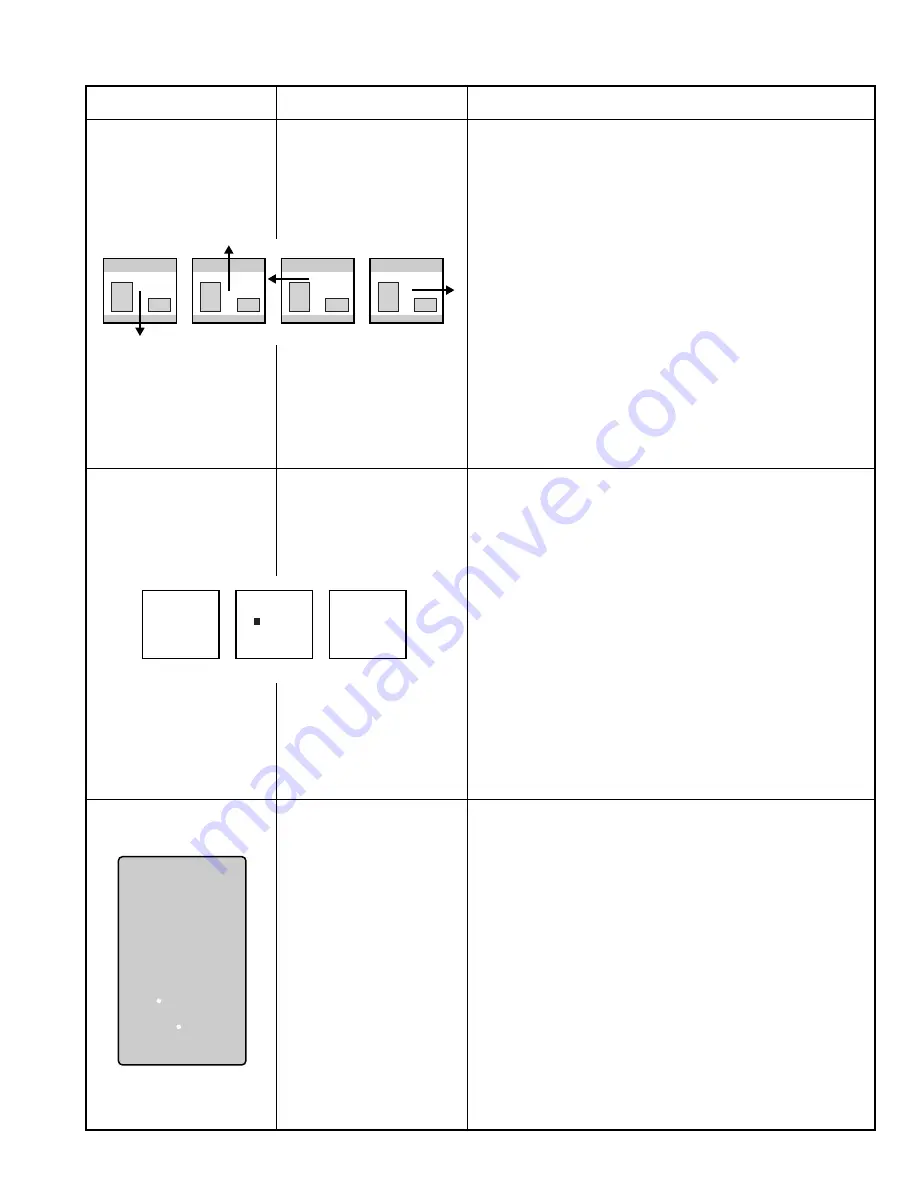

The picture position is

shifted vertically or horizon-

tally.

1) Setting of the retransfer

film

2) Ink ribbon, retransfer

film

3) Card

1) Refer to page 31 of the instruction manual and check the

film type setting.

2) Check the winding condition of the ink ribbon and the

retransfer film.

If the winding is not uniform, check the condition of the

shaft of the ink cassette.

3) In case of preprinted cards, use "Offset Prt Y" or "Offset

Trf X" of maintenance in service mode to adjust the posi-

tion to that design.

R e s i n c h a r a c t e r s a r e

blurred

Resin characters are thin.

Resin characters are miss-

ing parts.

* Resin character : When a

character is printed in black

ink.

1) Character font

2) Head or platen roller

wear

1) When small characters are printed with a fine font, the

characters may become blurred or may be missing some

parts.

In such a case, increase the character size or use bold

characters.

In case of using small characters due to print image de-

sign , refer to page 30 of the instruction manual.

2) When the head or the platen roller is worn out due to long

time use, characters may be printed with some parts miss-

ing. In that case replace with a new head or platen roller.

The printing result shows

white spots.

1) Dust on the card

2) Dirty cleaning roller

3) Dirty internal rollers

4) Dirty filter

This case occurs with printing to film.

(This is different from defective retransfer.)

1) Remove any dirt from the cards.

2) Clean the cleaning roller. Exchange the cleaning roller if

needed.

3) Clean the internal rollers with cleaning card.

4) Clean the fan filters. Exchange the filters if needed.

5) When this occurs every time at the same position in hori-

zontal direction, a dent in the platen roller or retransfer

roller can be considered.

123456789

123456789

123456789

123456789

ABCDE

ABCDE

ABCDE