62

1. Cleaning

The following parts should be cleaned as instructed of the list when you repair the unit.

CX320-HD1

Head assembly

30,000 screens

At the time of YMCK printing

TFS0116-002

C.L. roller assembly

About one year

Half a year with a high use frequency

TSS0181-002

Heater assembly

2,000 hours

With power save OFF

TSS0182-002

Reform heater assembly

2,000 hours

With power save OFF

CX220-FFK1

Fan filter assembly

About one year

KEF1041-002

Suction

40,000 hours

CX220-FAN2

Card cooling fan

20,000 hours

Operates only for retransfer.

KEF1037

Head cooling fan

40,000 hours

KEF1042-002

Ventilation

40,000 hours

CX220-PIM1

Card pick up motor

200,000 cards or more

DC motor

CX220-INW1

Ink take-up motor

180,000 screens

DC motor

CX220-INS1

Ink supply motor

180,000 screens

DC motor

CX220-MWM1

Film take-up motor

120,000 screens

DC motor

TSS0179-002

Platen solenoid

100,000 screens

KJY32771-045

Timing belt

100,000 screens

Belt for film supply motor and card feed motor

KJY32771-030

Timing belt

100,000 screens

Belt for card feed motor

KJY32771-044

Timing belt

100,000 screens

Belt for card feed motor

KJY32771-032

Timing belt

100,000 screens

Belt for card feed motor

KJY32771-035

Timing belt

100,000 screens

Belt for card feed motor

MAINTENANCE INSPECTIONS

Part No.

Part name

Replacement

Remarks

No.

Part name

Cleanning metod

1

Thermal head

Clean with alcohol .(dehydrated ethanol.)

2

Cleaning roller

Wash it after repair.

3

Feed roller

Clean with alcohol .(dehydrated ethanol.)

4

Card feed rollers

Use alcohol (anhydrous alcohol), or use a cleaning card and then implement

CLEANING in USER MODE.

5

Platen roller

Clean with alcohol. (dehydrated ethanol.)

6

Fan filters (three places)

Clean with the vacuum cleaner etc.

7

MG head

Use a cleaning card.

8

Bobbin inner

Clean with the vacuum cleaner etc.

9

Shaft of Ink Cassette / Film Cassette

Alcohol (Use anhydrous alcohol)

10

Bearings of each rotating part and around them

Clean with a vacuum cleaner, or wipe with a dry cloth

11

Card housing of hopper and around it

Clean with a vacuum cleaner, or wipe with a dry cloth

12

Interior of hopper

Clean with a vacuum cleaner, or wipe with a dry cloth

13

Inner side of front door, cassette slot

Clean with a vacuum cleaner, or wipe with a dry cloth

14

Dust inside set and on inner side of top cover

Remove the top cover, then clean the dust on the inner side and inside the

set with a vacuum cleaner.

3. Maintenance Inspections for Main Parts and Execution Standard

This standard table applies for standard conditions, and there may be large differences according to the use environment

and the use conditions. When the maintenance inspections are not performed suitably, the following times will not only be

shortened considerably, but there may also be other bad influences. However, deformation or ageing may occur for rubber

parts also when they are stored or not used for a long time.

Caution

Refer to the "Parts table" in the disassembly drawing for the

locations for application of oil or grease and the oil or grease

to be used.

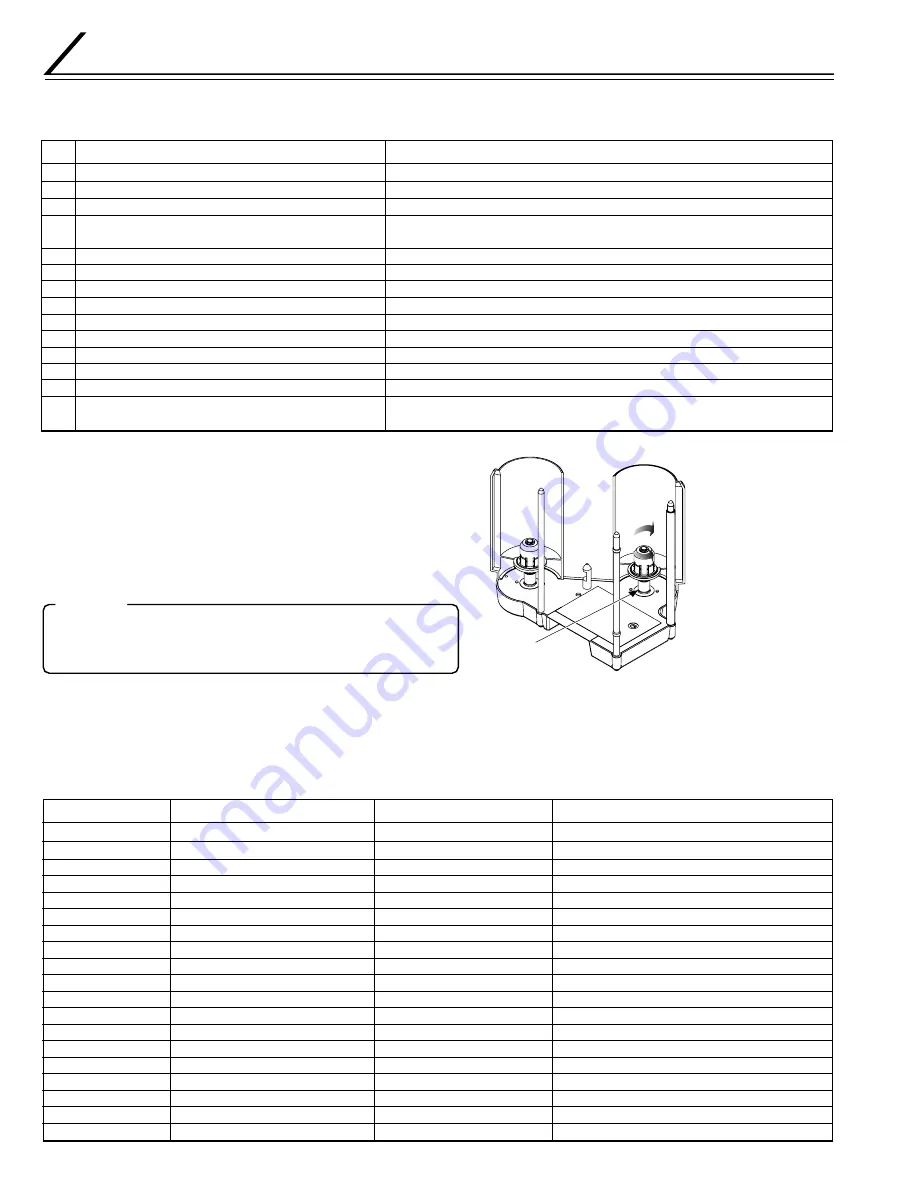

2. Lubrication

Apply the grease as illustrated to the ink ribbon cassette after

every 5,000 pcs of cards are printed. There is no need for

periodic application of oil or grease except this parts , but

application should be made to the new parts at the time of parts

exchange. When the oil or grease on the opposite part appears

dirty, wipe it off and apply new oil or grease.

Film cassette(green)

Apply the grease by

four grains of sesame

between the white

sheet and the spring of

the bobbin.And rotate

the bobbins to make

the grease uniformly

spread over the white

sheet.Wipe out the

excessive grease.

Supply bobin

(green)