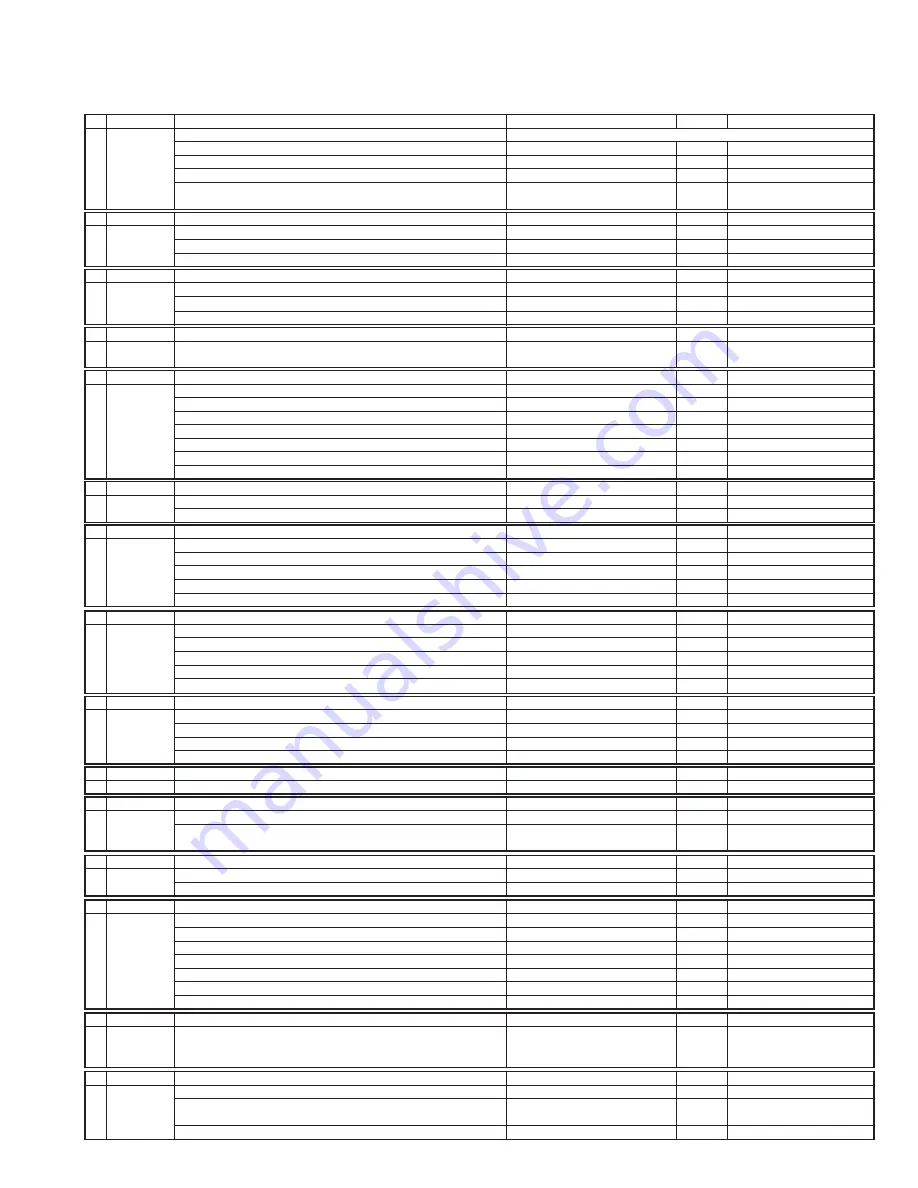

63

4. Periodic Inspection Items

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

1

Checks before

the inspection

Serial No.

Total No. of prints.

Head printing colors.

Confirmation of the take-up condition for ink ribbon and retransfer film.

Sample data printing (operation confirmation before the inspection).

1. Color pattern 2. Step pattern. Both sides, one card each

prints

colors

Uneven winding within 2 mm

Registration within 2 dots.

No thermal head wire break.

(Cleaning, exchange, adjustment)

No. of normally discharged cards

Counted for each color

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

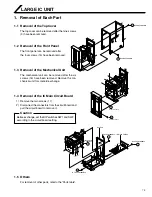

2

Related to

the supply tray

Check that the card passage opening permits only a single card to pass.

Check the operation of the card push lever.

Check for deformation of the lever of the supply tray detection switch.

Supply of only one card

Check for smooth movement when moved by hand.

An error is caused when the tray is removed.

Thickness switching plate

Push lever

Switch

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

3

Cassette-

related

Check for a bent or broken cassette shaft.

Check the rotation of the bobbin holder of the cassette.

Is the grease applied between the white sheet and the spring periodically.(every 5,000pcs cards)

No visual abnormalities

Check for smooth movement when moved by hand.

Check for uneven feed

Cassette

Cassette

Gray pattern

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

4

Related to

the turn unit

Use the turn unit motor test in service mode to turn the turn unit.

Smooth operation of the turn unit

Turn unit

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

6

Head-related

Disassembly/cleaning of the platen solenoid

Cleaning of the thermal head

Smooth movement of the plunger

No visual dirt

Exchange if the life has been exceeded.

The life is 30,000 screens.

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

7

Sensor-

related

Clean the slit of the ink start position sensor with a cotton swab.

Cleaning of the disk and the sensor for detection of the ink feed amount

Perform the "Ink Tup Enc" test in service mode.

Perform the "Ink SPY Enc" test in service mode.

Perform the "Media Tup Enc" test in service mode.

Start from Y of the ink

No color deviation

No error

No error

No error

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

8

Fan-related

Confirm that the head cooling fan is operating at all times.

Confirm operation of the card cooling fan at the time of film separation at the time of retransfer operation.

Confirm that the suction fan is operating at all times.

Confirm that the ventilation fan is operating at all times.

Clean all filters.

Operation at all times

Operation at the time of retransfer

Operation at all times

Operation at all times

No clogging

With normal use, the life is about one year.

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

9

Motor-related

Check the motor with the ink take-up motor test in service mode.

Check the motor with the ink supply motor test in service mode.

Check the motor with the retransfer film take-up motor test in service mode.

Check the motor with the card pick up motor test in service mode.

Smooth rotation at the time of start

Smooth rotation at the time of start

Smooth rotation at the time of start

Smooth rotation at the time of start

The life is about 180,000 screens.

The life is about 120,000 screens.

The life is about 200,000 cards.

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

5

Roller-related

Check the card supply feed roller surface for damage and deterioration and clean it.

Check the surface of the cleaning roller for damage, check the adhesive power, and clean it.

Check the surface of the roller in the turn unit for damage and deterioration and clean it.

Check the surfaces of the six card transport main rollers for damage and deterioration and clean them.

Check the surface of heat roller for damage and deterioration.

Remove the bend remedy roller and check the surface for damage and deterioration.

Clean the platen roller and finally print a gray pattern and check for white on a colored background.

There shall be a peak.

There shall be adhesive power after cleaning.

No visual defects

No visual defects

No visual defects

No visual defects

There shall be no white on a colored background.

Card supply roller

With normal use, the life is about one year.

Exchange when the life has been exceeded.

Exchange when the life has been exceeded.

Platen

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

10

Belt-related

Check all belts for stretching and lost teeth.

No elongation or lost teeth

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

11

MG-related

(when built in)

Perform MG head cleaning in user mode.

Perform the read/write test for the MG encoder in service mode.

In this case, there shall be no scratches to the stripe.

Cleaning

No errors.

No scratches.

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

12

IC-related

Perform the contact ON/OFF test for the contact IC encoder in service mode.

Disassembly/cleaning of the contact ON/OFF solenoid

Contact cleaning

Cleaning

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

14

Interlock-related Check that the buzzer sounds when the printer door is opened.

Confirm the following operations.

1. Cassette 2. Cleaning roller unit 3. Card tray

Error display on the LCD.

Error display on the LCD.

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

15

Final

confirmations

Perform printing of sample data from the personal computer (several cards continuously).

Printing of sample data (for storage)

1. Color pattern 2. Step pattern, one card each

Final cleaning. Switch off the power and clean the cleaning roller.

Communication test

Registration within 2 dots.

No thermal head wire break.

No.

Item

Inspection contents

Inspection standard

Work contents

Remarks

13

Printing-

related

Measure the position of an enclosure line.

Check that there is no uneven density of the Vth pattern.

Resin black confirmation

Confirm that there are no wrinkles.

Check that there are no scratches and no dirt.

Check that there are no retransfer defects.

Check for feed deviations.

X= , Y=

Check for uneven density.

Black ink confirmation

No wrinkles

No scratches, no dirt

No retransfer defects

No notable feed deviations.

Color pattern

Vth pattern

Black pattern

Step pattern

Gray pattern

In case of performing periodic inspections by means of a maintenance contract, please use a copy of the following sheet.