76

3.

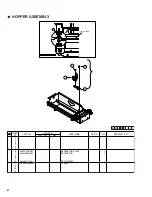

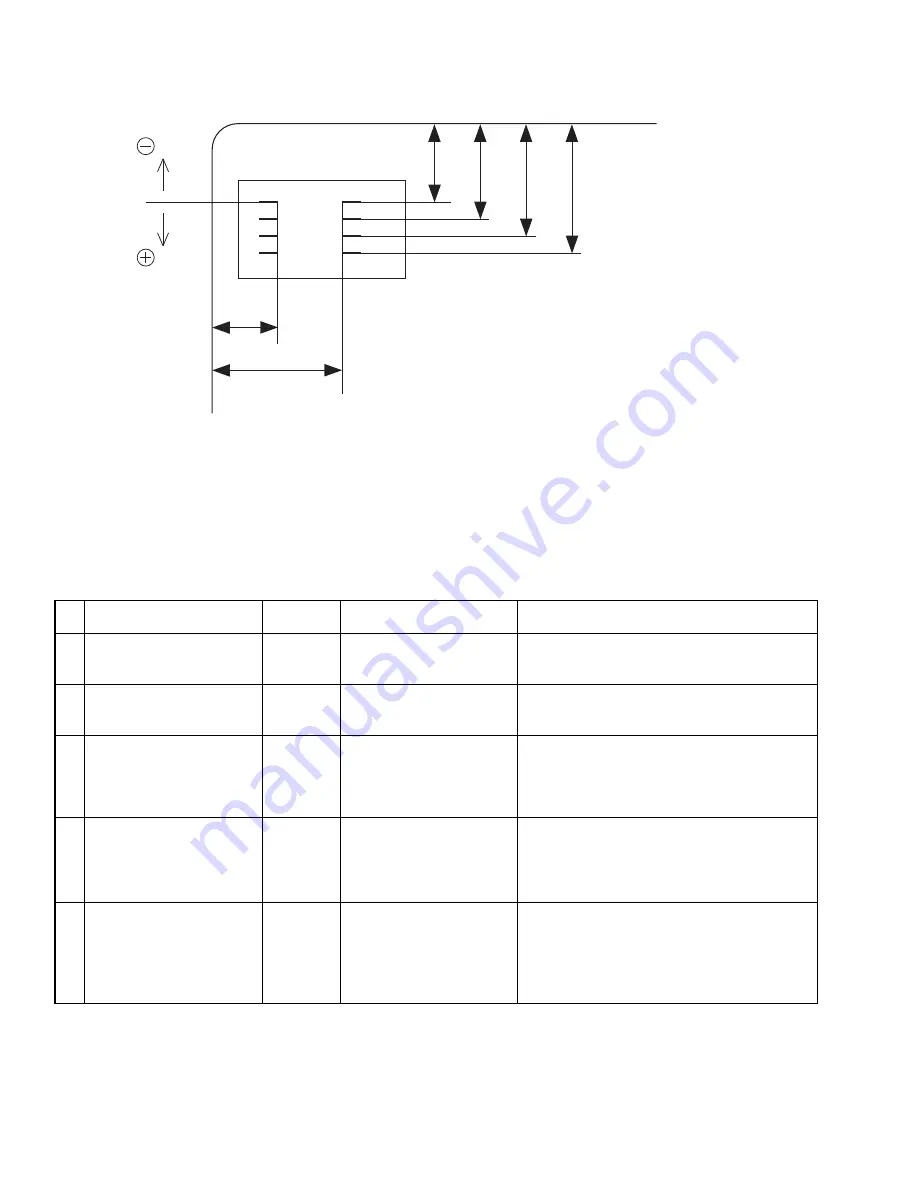

After completion of the test, measure the contact scratches on the CONTACT LABEL with slide calipers and confirm

that the above “a” and “f” are within the standard.

4.

When the values of “c” to “f” are outside the standard, first set the direction with bit 5 of SW1, and then set the

adjustment value with bits 6 to 8. The value of “c” to “f” can be adjusted, and "a" and "b" are only checked because

it cannot adjust.

4. Error Messages

(Standard)

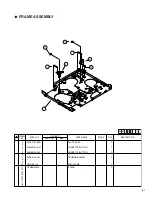

direction

direction

c

a

b

d

e

f

a : 10.25~12.25 mm

b : 17.87~19.87 mm

c : 19.23~20.93 mm

d : 21.77~23.47 mm

e : 24.31~26.01 mm

f : 26.85~28.55 mm

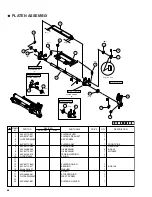

No

Printer LCD indication

Cause

IC unit

LED (D1)

EXT.Unconnected

EXT.SW Setting

EXT.jam

EXT.Communicate

No error message (when an

error has been detected on

the side of the personal

Lit

Blinking

Blinking

Blinking

Not lit

Disconnection 24V line

Switch setting error

Jam error

Communication error with

the printer

IC encoding error

Treatment

1) Is the printer I/F cable connected correctly?

2) Defective IC main circuit board

3) Is 24V output by the printer?

1) Are the DIP switch settings on the IC main

circuit board correct?

2) Defective IC main circuit board

1) Is card feed performed correctly?

¥ Card feed motor

¥ Defective IC main circuit board

¥ Defective card position sensor

¥ Dirty feed roller

1) Is the printer I/F cable connected correctly?

2) The IC main circuit board or the analog

circuit board of the printer unit is defective.

(Caused by connecting/disconnecting the printer

I/F cable while the power is on,)

1) Are the DIP switch settings on the IC main

circuit board correct?

2) Confirm the IC card setting direction.

3) Defective IC main circuit board

4) Check the card feed roller for dirt and clean

1

2

3

4

5