20

4.4.2.

Debugging Content

a)

Measuring and recording operating parameters of the unit (return air

temperature, air temperature, the liquid pipe pressure, intake

pressure, temperature of the valve before the intake air

temperature);

b)

Adjusting the operating parameters of the compressor (the

compressor suction, discharge pressure control in a suitable range,

and adjust the degree of superheat and subcooling to a suitable

value);

c)

Running the debug electrode humidifier (humidifier operating

current measurement), if no configuration is ignored;

d)

Running the debug electric heater (heater operating current

measurement).

[Note: Start-up operation by professional engineers to complete.]

5.

Maintenance

5.1.

Daily Operations

In the daily management of the engine room, the air conditioning for

precision management and maintenance mainly refrigeration systems,

fans, air filters, humidifiers, heaters, drainage and so on. The adequacy of

daily operations management, stable operation of the unit will, life and

energy savings has a significant impact, and please users strictly enforce

the daily management of precision air conditioning.

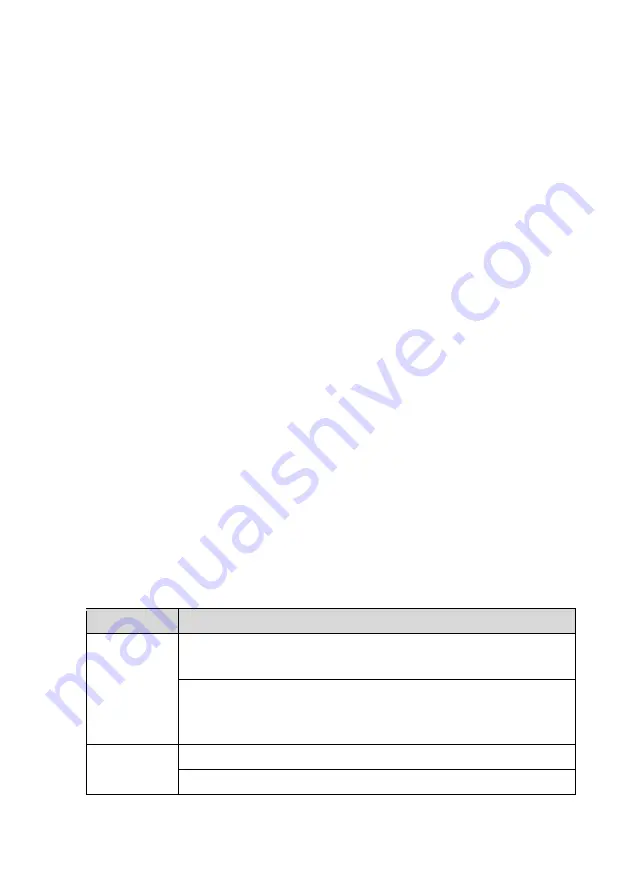

Table 5-1 Daily operations project

Project

Content

Tour

Check that the air conditioning system in normal

operation

Various functions and parameters are normal, if an

alarm situation to check the alarm log, and analyze the

cause of the alarm

Ventilation

system

Check the Fan If abnormal noise

Check that the motor current is normal