45

2.

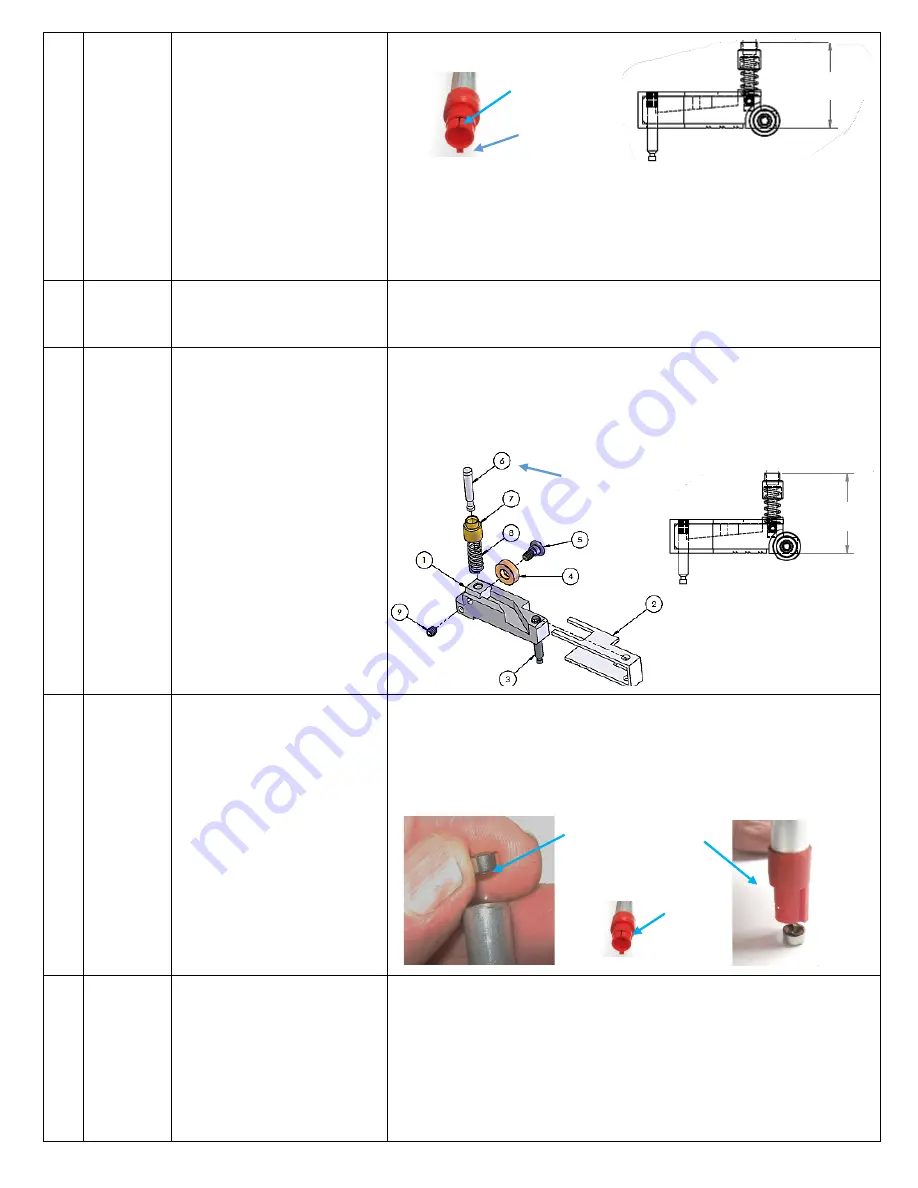

To replace the tip, remove the old tip and gently start the new tip on the

aluminum Magazine tube. Make sure it is the correct size/color for the primers

used—Blue for Small Primers and Red for Large Primers. Put the Magazine Tube

in the Magazine Shield Tube and orient the tip in the mating slot inside the

primer feed body. Screw magazine Cap on and gently use this to push the

magazine tip on the rest of the way—do not over tighten.

Primer Slide is not moving

smoothly back and forth

1.

The Primer Roller or White Slide Bearing is dirty or worn. Disassemble and clean

the Roller and both sides of the Primer Slide Bearing with Alcohol and reinstall

using no lube! If worn call Dillon for a new Bearing.

Primer Slide Punch, Cup and or

Spring are Dirty or have come apart

1.

Disassemble Punch (6), Cup (7), and Spring (8) by loosening Set Screw (9), clean

with alcohol, and dry.

2.

Re-assemble by fully compressing the Punch, Cup and Spring until they stop

moving and firmly re-tightening the Set Screw (9)—Compressing the

Spring requires some force—do not damage the top of the cup when doing this.

The installed height should be as shown below—1.404±.005”

Primer is not “Dropping" through

the Magazine Tube

1.

Perform a single primer drop test with the Magazine Tube out of the system.

Hold the Mag Tube vertically with the tip resting on a flat surface. Drop one

primer into the top of the tube, shiny side down. Gently pick up the tube. The

Primer should be sitting on the flat surface. If not, check the tip for damage and

or burrs on the semicircular "fingers." If no damage and the primer is caught in

the “fingers”, gently and very lightly open the two "fingers." Try the test again.

If still unsuccessful, replace the Tip and perform the test until successful.

1.

Crushed primers

1.

Dirt or debris in Shellplate pockets. Remove with a pick or similar tool.

2.

Crimped primer military brass. Military primer pockets must be chamfered or

swaged before priming.

3.

“Ringed” primer pocket. A remnant of the primer cup remains in the primer

pocket after being de-primed.

4.

Primer Punch is not assembled correctly in the Primer Slide.

5.

Wrong size/type primer for that caliber.

6.

Abrupt or jerky movement of the Operating Handle. Cycle the machine using a

smooth motion. Slow down during the primer-seating step; be ready to stop if

the primer is not seating smoothly or there is excessive seating resistance.

"Fingers"

Alignment Tab

Drop primer into top of

Mag Tube Held vertically

on a flat surface--Primer

should fall freely through

tip on to flat surface

1.404±.005

1.404±.005

"Fingers"

Summary of Contents for Square Deal B

Page 50: ...50 13 DILLON PRECISION Square Deal B EXPLODED VIEWS AND PARTS IDENTIFIER 13 1 Main Assembly ...

Page 51: ...51 13 2 Frame and Lower Assembly Index Assembly Index Assembly installed in Frame Index Pawl ...

Page 52: ...52 13 3 Typical Toolhead Assembly 45ACP Shown ...

Page 53: ...53 13 4 Automatic Primer Assembly ...

Page 55: ...55 13 6 Primer Early Warning System ...