10

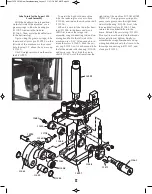

place as shown in

Fig. 22

, pull the re-

taining pin and allow the primers to

drop into the magazine. Pivot the switch

the lever back over the Early Warning

System housing. Gently slide the fol-

lower rod down through the switch

lever and into the primer magazine

tube. When you are nearly out of

primers, approximately three remaining,

the follower will activate the buzzer.

The Electric Casefeeder

Use only clean cartridge cases that

have been inspected for any potential

problems; split cases, rocks or smaller

caliber cartridges that may be hidden in

larger caliber cartridges.

Fig 23

Warning:

Be sure that no loaded

rounds are mixed with your empty cases.

It is possible to feed a blunt nosed car-

tridge like a .38 Sp. WC into the

shellplate upside down and explode it

when it is hit by the decap pin.

Now fill the casefeed bowl with ap-

proximately 500 pistol cases or about

350 rifle cases.

Fig 24

Your Super 1050 is now charged with

components and ready to go, but before

you start reloading, read the following

explanation of the sequence of the eight

reloading stations and the processes that

are done at each station.

Review: How the Super 1050

Works

Stations 1 - 8 (counterclockwise)

Station 1:

Empty cases are automati-

cally inserted into the shellplate via the

electric casefeeder.

Station 2:

Here the spent cartridge

cases are resized and deprimed.

Station 3:

This station is totally unique.

The case is supported from the inside

and slightly expanded (not belled) while

simultaneously a swager is driven into

the primer pocket to remove any crimp.

Station 4:

A new primer is installed

at this station. The spring driven primer

slide is extremely smooth. The steel

shrouded primer magazine is capped

with an electronic Early Warning De-

vice to let you know when you’re

down to approximately three primers.

Station 5:

Here the case is belled and

powder is dropped by the case-activated

powder measure. It is extremely accurate

and will not drop powder unless a case

is present. Dillon Precision offers an op-

tional accessory to be utilized with the

automatic powder measure at this station

– Dillon’s Low Powder Sensor provides

an audible and visual reminder when it’s

time to refill the powder reservoir.

Station 6:

This station is open to allow

for case inspection.

Station 7:

The bullet is seated to its

proper depth at this station.

Station 8:

In this station, the bullet is

crimped into place. The cartridge is then

automatically ejected into a collection

bin.

As stated earlier, your dies have been

adjusted at the factory. Before you

change anything, try it the way it is,

once you thoroughly understand the

machine’s operation, make whatever

adjustments to the dies you feel neces-

sary.

Reminder: There may be some varia-

tion due to components.

To Begin Reloading

Turn on the switch on the front of the

casefeed motor housing. The casefeeder

plate should begin to turn. Cases will

begin to dispense, base down, into the

clear plastic casefeed tube. The motor

will continue to run until the tube is full,

at which point a micro-switch will tem-

porarily stop the case flow.

From this point the casefeeder will au-

tomatically fill the tube as you reload. If

the casefeeder does not function prop-

erly or the cases do not fall base down,

refer to the Troubleshooting section of

this manual.

Fig. 24 - The casefeed bowl will hold approx-

imately 500 pistol cases or 350 rifle cases.

Do not overload the casefeed bowl.

Fig. 23 - When loading, use only cleaned and

inspected cartridge cases.

Station 1 - The casefeed plunger inserts the

case into the shellplate.

Fig. 25 - Dillon’s Low Powder Sensor gives

an audible and visual warning when the

powder reservoir gets low.

Super 1050 2018 New Casefeeder.qxp_Layout 1 1/31/18 6:47 AM Page 10