11

Pull the operating handle smoothly to

the bottom stop, then raise the handle, a

case has been fed to

Station 1

. Cycle the

handle again, strive to be smooth in your

operation.

The first case should be indexed to

Station 2

. Cycle the handle again.

It is not necessary to apply any force

on the upstroke of the handle. All you

are doing on the upstroke is indexing the

shellplate. Remember that priming is

done on the down stroke. A slow meas-

ured upstroke gives you lots of time to

pick up the next bullet and ready it for

seating. If you count one second down,

and one second up, you’ll have a good

pace.

The first case should now be in

Station

3

with a case in Stations 1 & 2 as well.

Cycle the handle again. The case is

swaged and expanded at Station 3. Ob-

serve the swage operating part

(#20314*), if the swage is proper, pro-

ceed – if not see items 3 and 4 in the

Troubleshooting section of this manual.

Cycle the handle again and the case gets

primed at

Station 4

.

If the primer is not seated properly (too

high or too deep) you will need to adjust

the primer push rod (#12819). Clockwise

turns of the primer push rod will cause

the primer to be seated deeper while

counterclockwise turns will seat the

primer higher.

The first case in the sequence should

now be primed and at

Station 5

. Re-

move the locator button (#20637*), ex-

tract the round and check the primer. If

everything looks okay, replace the case

and button and proceed. However, if

the primer is not seated properly (too

high or too deep) you will need to adjust

the primer push rod (#12819). Clockwise

turns of the primer push rod will cause

the primer to be seated deeper while

counterclockwise turns will seat the

primer higher.

Cycle the handle again, the automatic

powder measure will drop the charge

you’ve selected. Pistol casemouths will

be belled at this time. Look through the

inspection hole in

Station 6

– you should

be able to see your powder charge in the

case.

Cycle the handle again. Now, with

your left hand, place a bullet on the

powder-charged case at

Station 7

and

cycle the handle. Your bullet will be

seated to its proper depth, if not, a sim-

ple height adjustment to the seating stem

may be necessary. Refer to a loading

manual for proper loaded length (OAL).

Cycle the handle again and check for

crimp at

Station 8

. Refer to Troubleshoot-

ing item 8 for adjustments if necessary.

Add a bullet, cycle again. Your first

loaded round should now be ejected into

the collection bin.

If all has gone well to this point you’ve

got it made. Just keep adding bullets,

watch your fingers so they don’t get

caught and don’t hurry. Just try to be

smooth in your operation. The speed will

come naturally and you’ll be doing a

thousand rounds per hour before you

even realize it.

The following are some adjustment

suggestions as well as Troubleshooting

hints.

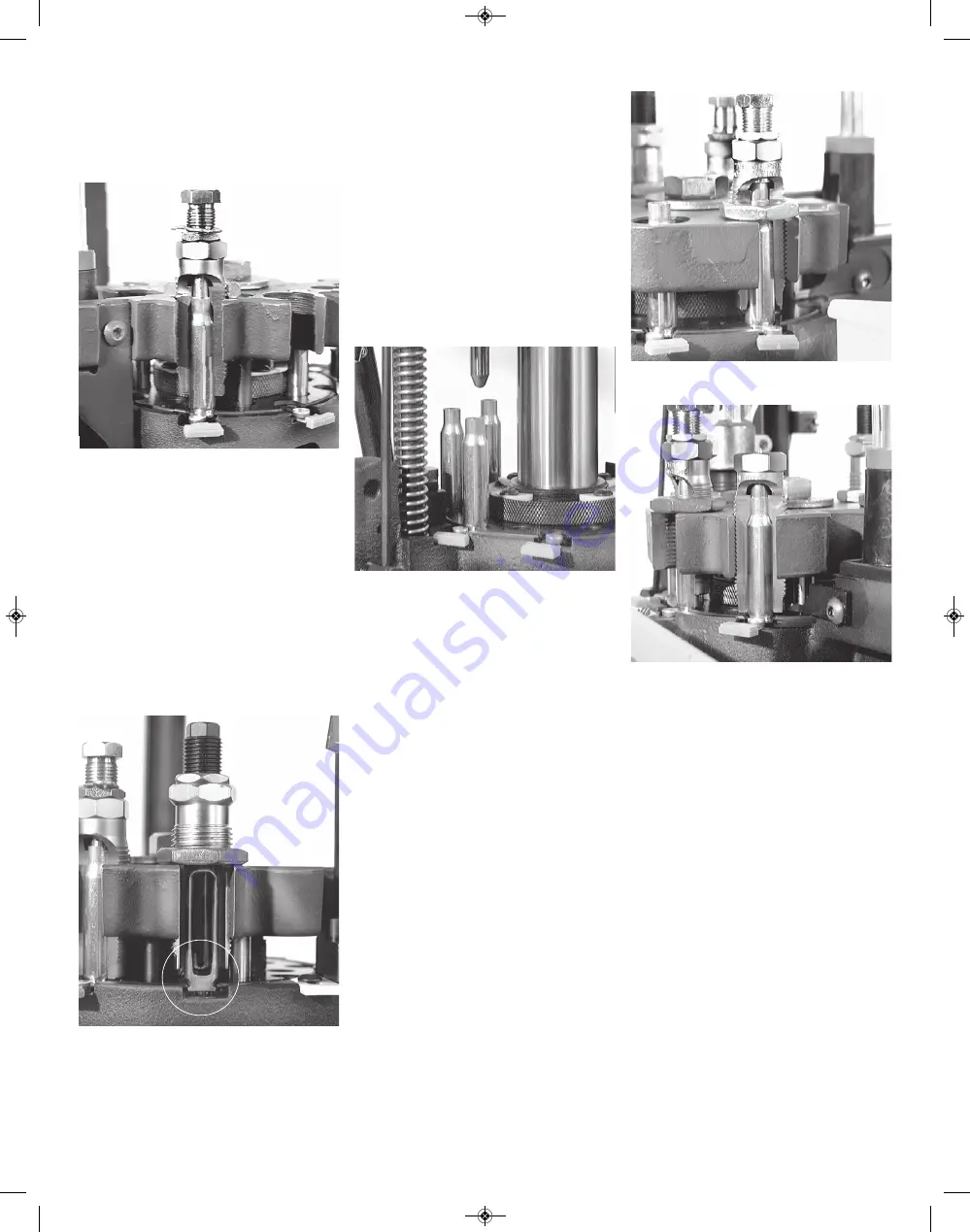

Station 5 - Here the case mouth is belled

and powder dispensed.

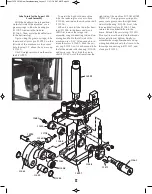

Station 2 - Here, spent cartridge cases are

resized and deprimed.

Station 7 - In this station, the bullet is seated

to its proper depth.

Station 8 - Here the case is crimped and

then ejected out of the shellplate with the

next pull of the handle.

Station 3 - Here the case mouth is ex-

panded while a rod supports the case base

for swaging.

Super 1050 2018 New Casefeeder.qxp_Layout 1 1/31/18 6:47 AM Page 11