12

Adjustments

Casefeeder

It may be necessary to readjust the

micro-switch for different calibers.

Cases may become lodged between the

micro-switch and the tube wall. The

other extreme is the case failing to put

enough pressure on the micro-switch to

shut off the system causing it to con-

tinue running and over flowing the

tube.

Remove the two clutch screws

(#13732), lock washer (#13813) and

upper clutch (#13632) and the casefeed

plate. Place the spacer on the shoulder

of the lower clutch and reassemble –

see the schematic on page 31 for more

details. The casefeed plate should now

be approximately 1/8” above the floor

of the casefeed bowl. Note: Make sure

the casefeed plate is centered in the

bowl.

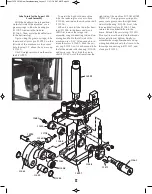

Fig. 26

Handle

The operating handle is adjustable to

three different length settings

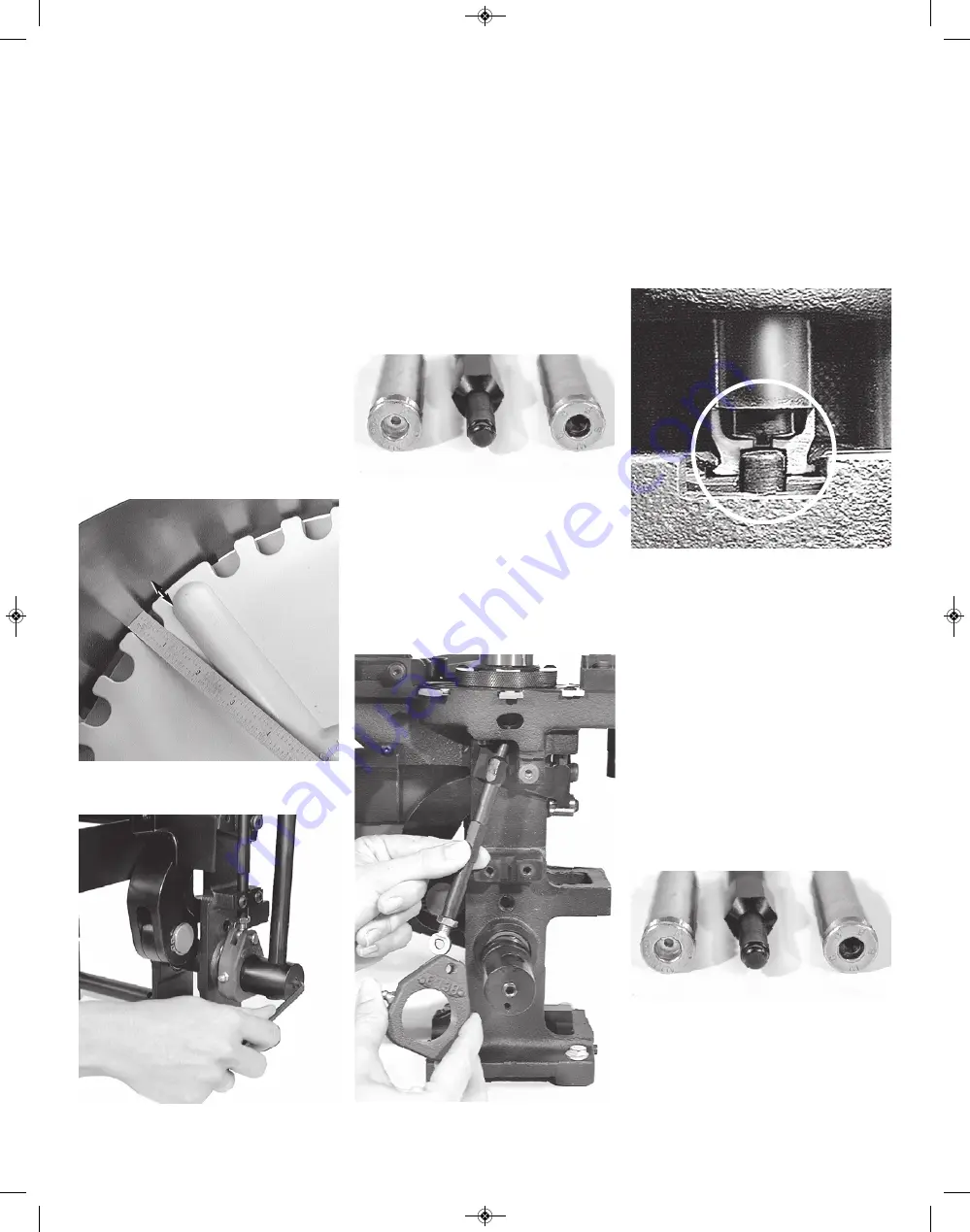

Fig. 27

.

Choose the one most comfortable for

your operation. Loosen the set screw

(#13432) then retighten when the handle

is in the most comfortable position.

Swager

Swaging on the Super 1050 is a simple

process and is necessary on all cartridge

cases as a means of uniforming the en-

trance of the primer pocket.

Fig. 28

The

swage rod (#20314 large or #20313 -

small) is fully adjustable.

Swage Conversion and Adjust-

ment Conversion – Fig. 29

Begin by removing the swage cover

(#13064). Next remove the hitch pin

(#13840) and slide out the clevis pin

(#13522). Remove the operating handle.

Rotate the swage connecting rod a half

turn and remove it. This will allow you

access to the swager. Pull the swager

down and out of the machine.

Fig. 29

Insert the new swager and reassem-

ble.

Swage Adjustments

Use ONLY an unswaged military case

for these adjustments.

With the handle in the down posi-

tion, screw the swage back-up ex-

pander down until it makes contact

with the case bottom and holds it in

place.

Fig. 30

With the handle still in the down posi-

tion, turn the swage rod up until it makes

contact with the case bottom.

Raise the handle halfway and rotate

the swage rod a quarter turn. Now, cycle

the handle. Inspect the case and when

you achieve a completed swage of the

primer pocket, tighten the swage lock nut

(#14067).

A properly swaged pocket will show

a rounded edge around the rim. Some

military cases (.223 & .308) start out

with three small dents around the base

Fig. 26 - Make sure the casefeed plate is cen-

tered in the bowl with approximately 1/8”

all the way around.

Fig. 29 - See the schematics on page 28 for

more details.

Fig. 28 - Note the difference between the

swaged primer pocket (left) and the

unswaged primer pocket (right).

Fig. 31 - Note the difference between the

swaged primer pocket (left) and the

unswaged primer pocket (right).

Fig. 27 - Note that there are three different

positions for mounting the operating handle.

Fig. 30 - A cutaway view of a .45 ACP with

the swage rod and the back-up rod properly

adjusted in the swaging position.

1/8”

Super 1050 2018 New Casefeeder.qxp_Layout 1 1/31/18 6:47 AM Page 12