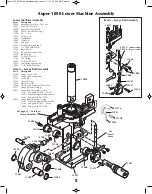

14

that there is a specially designed screw-

driver supplied for the bushing (in-

cluded in the accessory bag).

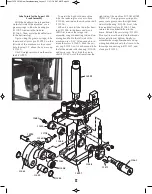

Fig. 40

You should clean your machine at

this time.

Fig. 41

Prior to installation, lube the base of

the primer punch. Now adjust your new

punch (#12849 - large or #13307 -

small) so that it is flush with the bushing

(#13130 - large or #13222 - small) by

turning set screw (#13226) up or down.

If the primer punch is too low, dirt will

collect on top of it leaving imprints on

your primers. If it is too high it will bind

the slide. Note: You can use the slide for

a guide. Slide it back and forth over the

bushing to check your adjustments. See

the schematic on page 29 or the trou-

bleshooting section for additional infor-

mation.

To return the lever arm bracket assem-

bly to proper position, manually move

the primer slide underneath the

shellplate. Pull the operating handle

down. Loosen the bracket screw, slide

the assembly down until it touches the

bottom of the primer slide slot in the

frame. Back the bracket up about .010”,

retighten bracket screw.

Toolhead Removal

Disconnect the powder bar return rod

(#13960) from the bellcrank (#11234) by

releasing the return rod clip (#13929).

Fig. 42

Remove the Primer Early Warning de-

vice.

Raise the primer slide lever assembly

(#20488) and lock in place - see

Fig. 34

.

Obtain a 15/16” socket or wrench

(not supplied) to remove the toolhead

bolt (#13342) and washer (#13449).

Fig. 43

Now remove the toolhead (#20420).

Due to being spring loaded, there will be

some resistance. Wiggle the toolhead up

and off while holding the handle.

After removing the toolhead, carefully

lower the handle.

When reinstalling the toolhead bolt

(#13342) turn it in only finger tight then

cycle the handle up and down to make

sure everything is properly located. With

the handle in the down position, tighten

the toolhead bolt with the above men-

tioned wrench.

Shellplate Removal

Loosen the ejector tab screw

(#13896) and swing the ejector tab

(#13189) out of the way.

Fig. 38

Loosen the four locator tab screws

(#13895) about four full turns.

Fig. 37

Use a toothbrush to remove any pow-

der that may be in the threads before re-

moving the lock ring.

Next remove the lock ring (#20311).

Now push the casefeed plunger back

(#13073*) and lift the shellplate off. Be

sure to lightly grease the bore of the

shellplate when reinstalling it.

Fig. 44

Rule of thumb: turn the lock ring

down until tight then back off one-eighth

of a turn. Then tighten the four locator

tab screws (#13895).

Fig. 39 - Rotate the primer slide stop 90˚ to

move the primer slide freely in or out.

Fig. 40 - A special screwdriver for the bush-

ing has been included in your accessory bag.

Fig. 41 - It is very important to keep the ma-

chine free of grit and debris.

Fig. 44 - Your machine will work its best

when properly cleaned and lubricated.

Fig. 43 - Due to being spring loaded, there

will be some resistance when pulling the

toolhead off.

Fig. 42 - After removing the clip and discon-

necting the rod, replace the clip in the rod

for safe-keeping.

slide stop

Super 1050 2018 New Casefeeder.qxp_Layout 1 1/31/18 6:47 AM Page 14