4

www.dimplex.com

MAINTENANCE

WARNINg:

Disconnect all power coming to fireplace at

main service panel before attempting any maintenance

or cleaning to reduce risk of fire, electric shock or

damage to persons.

WARNINg:

If the fireplace was operating prior to

servicing allow at least 10 minutes for light bulbs and

heating elements to cool off to avoid accidental burning

of skin.

Light Bulb Replacement

Light bulbs need to be replaced when you notice a dark

section of the flame of when the clarity is reduced. There

are four bulbs under the log set which generate the flames

and embers.

Helpful Hints:

It is a good idea to replace all light bulbs

at one time if they are close to the end of their rated life.

Group replacement will reduce the number of times you

need to open the unit to replace light bulbs. Long life

bulbs are recommended to reduce the frequency of bulb

changes.

Bulb Requirements:

Quantity of 4 clear chandelier or

candelabra bulbs with an E-12 (small) socket base, 60 watt

rating. Example: GE 60BC or Philips 60CTC.

Do not exceed 60 Watts per bulb.

Tool Requirements:

Philips Screw Driver

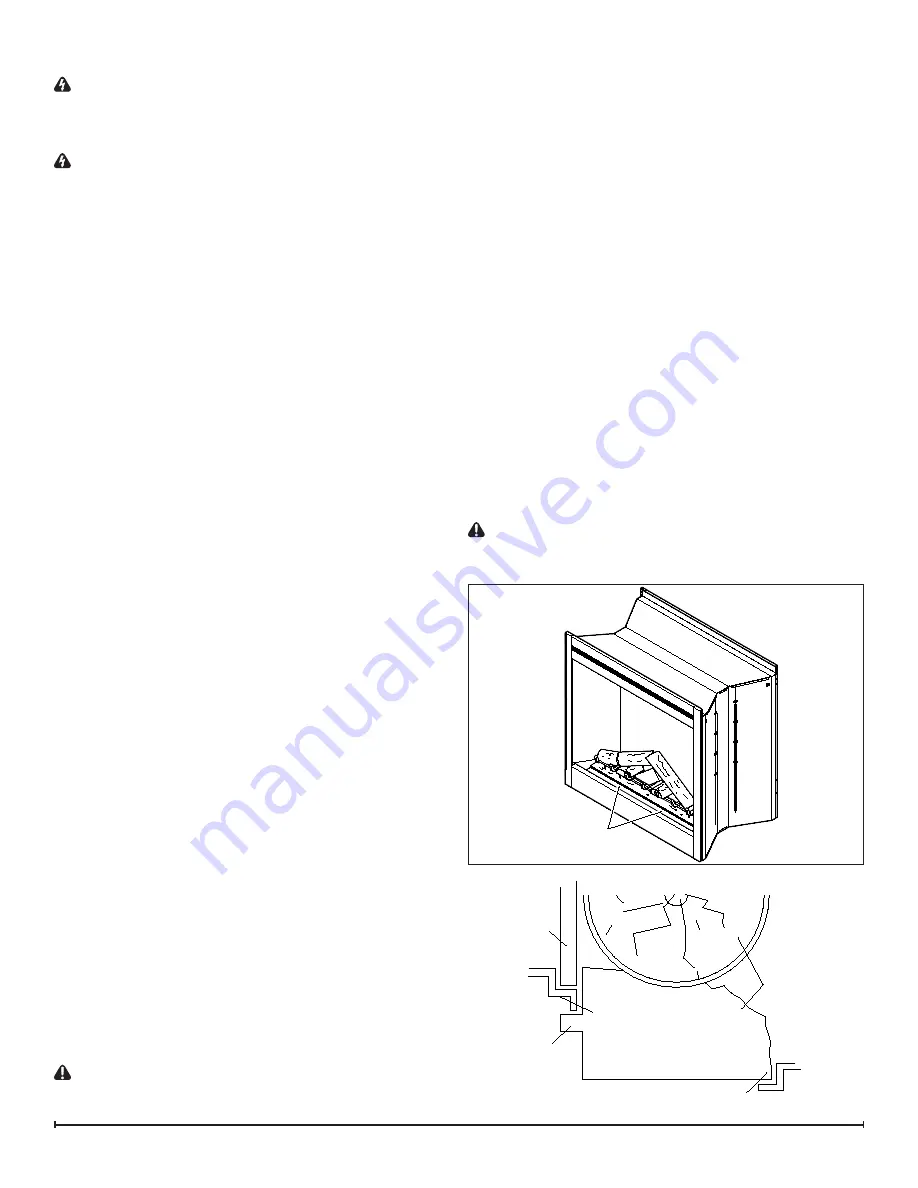

Open steel curtain (remove glass doors if applicable).

1.

The bulbs can be accessed from either side of the

fireplace.

Remove two screws on log bracket and remove log

2.

plate (Figure 3).

Pull the rear edge of the log set forward by grasping

3.

the ember bed by the sides, pull firmly until the rear tab

pops out from under the back ledge, then lift the logs

out. (Figure 4)

!

IMPORTANT:

Only handle the log-set by the plastic

ember-bed, not the logs themselves.

!

NOTE:

Log-set fits tightly into firebox. Some force may

be necessary to remove.

Examine the bulbs to determine which bulbs require

4.

replacement.

Remove the flicker rod. Begin by removing the plastic

5.

grommet, which holds the end of the rod in the left

bracket. Grasp and turn it ¼ turn, releasing it from the

slot in the bracket, and then lift it out of the bracket.

The motor side of the rod may be attached to the motor

6.

in one of two ways:

Secured with a spring - attach needle nose pliers to

•

the spring on the motor shaft and pull while rotating in

the same direction of the spring winding.

Secured with a rubber gasket - pull and twist the gas-

•

ket away from the motor simultaneously until it comes

off the motor shaft.

CAUTION:

Ensure that the flicker rod does not get

bent during removal and re-connecting, ensure the rod is

straight when replaced, otherwise, it may cause excessive

noise during operation.

!

NOTE:

To replace the flicker rod that uses a spring,

attach needle nose pliers to the flicker rod spring and push

onto the flicker motor shaft while rotating in the opposite

direction of the spring winding.

Unscrew bulbs counter clockwise.

7.

Insert new bulbs.

8.

Reassemble in the reverse order as above.

9.

!

NOTE:

To replace the log set insert the front edge,

pushing back down until the rear tab snaps under the back

ledge and the logs are resting against the partially reflective

glass.

Partially Reflective Glass Cleaning

The partially reflective glass is cleaned in the factory during

the assembly operation. During shipment, installation,

handling, etc., the partially reflective glass surface may

collect dust particles; these can be removed by buffing

lightly with a clean dry cloth.

To remove fingerprints or other marks, the partially

reflective glass can be cleaned with a damp cloth using

good quality household glass cleaner. The partially

reflective glass should be completely dried with a lint free

cloth or paper towel.

CAUTION:

Do not use abrasive cleaners on partially

reflective glass surface or spray liquids directly onto any

surface.

Figure 3

Ember Bed

Assembly

Front Edge

Rear Tab

Back Ledge

Mirror

Figure 4

SCREWS