11

11. Re-assemble the firebox in reverse order.

!

NOTE:

Ensure the rear tab/ledge on the log-set/em-

ber-bed is installed tightly under the bottom of the partially

reflective glass to prevent light leakage.

HEATER ASSEMBLY REPLACEMENT

Tools Required:

Philips head screwdriver

Needle nose pliers

CAUTION:

Follow “Preparation for Service” instructions

before proceeding.

1. Remove 9 screws that secure the top panel to the side

panels of the firebox using a Philips head screwdriver,

2 on the left side; 2 on the right side; 3 on the backside;

2 on the top.

2. Lift the top off the firebox. Turning the panel 45 de-

grees, rest it inside the cavity at the top to provide you

with some support and leverage while following Steps

4 & 5.

3. Noting their original location, disconnect the wires at-

tached to the end of the heater assembly on the blower

motor and element. Using a flat head screwdriver gen-

tly pry between the end of the connector and the heater

to release the wires

!

NOTE:

Some of the wires may have a “piggy-back”

connector that allows a second wire to connect to the same

prong as the first wire. Keep the “piggy-back” connection

together when pulling the wires off the heater assembly.

!

NOTE:

In some cases the wire running from the

cutout will not reach the terminal block where the previous

wire was removed from, see Figure 8. The new wire is

provided with an insert connection, slide the plastic cover

up and bend the connection in half. Remove the wire on

the blower motor, that is running from the same spot off of

the terminal block, install the new bent wire, then install the

previously removed wire onto the bent connection.

4. Remove the 2 mounting brackets that attach the heater

assembly to the top panel. Ensure that the heater as-

sembly is supported when removing the brackets.

5. Remove the mounting brackets from the heater as-

sembly by removing the 2 Philips screws from each

bracket.

6. Attach the brackets to the new heater assembly and

then attach brackets to the top panel.

7. Re-assemble in reverse order as above.

HIGH TEMPERATURE CUTOUT

REPLACEMENT

Tools Required:

Philips head screwdriver

Needle nose pliers

CAUTION:

Follow “Preparation for Service” instructions

before proceeding.

1. Remove 9 screws that secure the top panel to the side

panels of the firebox using a Philips head screwdriver,

2 on the left side; 2 on the right side; 3 on the backside;

2 on the top.

2. Lift the top off the firebox. Turning the panel 45 de-

grees, rest it inside the cavity in the top to provide you

with some support and leverage while following Step 4.

CAUTION:

Support the back underside of the firebox

with a small piece of wood as the feet do not go the entire

depth of the unit and it can easily tip backwards.

3. Remove the 2 mounting brackets that attach to the

heater assembly to the top panel. Ensure that the heat-

er assembly is supported when removing the brackets.

4. Locate the High Temperature Cutout found on the outer

casing of the heater assembly at the elements.

5. Follow the wires to the terminal block and disconnect

the 2 wires at the terminal block.

6. Using a small diameter, Philips screwdriver, remove the

old cutout and replace it with the new one following the

orientation of the original wires. (See Assembly Part

Pictures)

!

NOTE:

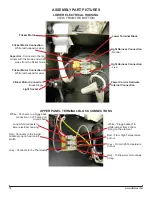

In some cases the wire running from the

cutout will not reach the terminal block where the previous

wire was removed from, see Figure 8. The new wire is

SHORT CONNECTION

BLOWER HEATER ASSEMBLY

TERMINAL BLOCK

ENSURE WIRE IS ROUTED AROUND BLOWER

TERMINAL BLOCK

BLOWER HEATER ASSEMBLY

Figure 8

BEND

HERE

Original Wiring

New Wiring