10

www.dimplex.com

If the 3 bottom screws to the front panel are accessible

2.

in your application, you can remove them to obtain the

most clearance for the repair. If they are not acces-

sible, you can still proceed with them attached and

pulling the front panel forward from the top end by ap-

proximately 2” inches.

Remove the electrical junction box cover located on the

3.

bottom right hand side by removing the 1 screw on a

small mounting-flange on the front face of the junction

box cover. Lift the cover out and set aside. Once the

cover is removed, the flicker motor and terminal block

will now be visible.

Remove the flicker motor wires from the terminal block

4.

by removing the 3 small Philips screws holding each

wire in place then gently pulling the wires out of the

terminal block. Note their original locations, (black

wire towards the front, white in the middle and brown

to the back). Also note that the white and the brown

wires each include a capacitor lead going into the same

terminal. (The writing on the capacitor should be facing

upward when re-inserting the wires from the new mo-

tor).

Remove the 2 screws holding the flicker motor to the

5.

mounting bracket. Gently pull the motor away from the

flicker rod.

CAUTION:

When removing and replacing the flicker

motor try to keep any slight bending of the flicker rod

minimal so as to not damage it. If flicker rod is damaged, it

should be replaced to ensure proper operation.

Properly orientate the new flicker motor onto the motor

6.

bracket and re-attach with the 2 mounting screws.

Reassemble in the reverse order as above.

7.

ELEMENT REPLACEMENT

Tools required:

Phillips head screw driver.

Needle nosed pliers.

Small cutter or snips

3/8” ratchet or wrench

CAUTION:

Follow “Preparation for Service” instructions

before proceeding.

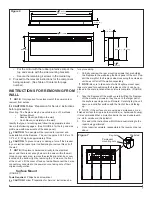

Remove the 4 screws that secure the angled switch

1.

housing cover located just below the manual control

switches on the top right. Remove cover and set aside.

Remove the panel that spans across the top front facia.

2.

To do so, locate 4 screws, (2) on the left and (2) right

on the angled part behind the facia. Wires from the

switch housing are connected to this piece so carefully

move it farther down in the body of the unit, to give

some room to access the heater assembly cover.

Remove the heater assembly cover in the top center by

3.

removing the 10 screws on the side brackets, (5) on the

left and (5) on the right. Wires from the switch housing

are also connected to this piece, so carefully move it

farther down in the body of the unit, to give some room

to access the heater assembly housing.

Release the top panel of the heater assembly hous-

4.

ing by removing 4 screws on the side brackets, (2) left

and (2) right. Pull the top panel of the heater assembly

housing out from between the brackets.

From the top panel of the heater assembly housing, re

-

5.

move the 4 screws, (2) on the far left and (2) on the far

right that hold the element cover to the housing panel.

Disconnect wires from the ends of the elements noting

6.

their original locations. Pliers may be required for grip

when disconnecting the wire/spade connectors.

!

NOTE:

Some of the wires may have a “piggy-back”

connector that allows a second wire to connect to the same

prong as the first wire. (Two wires will connect on one

prong). Try and keep the “piggy-back” connection together

when pulling the wires off the circuit board.

Using a 3/8” ratchet or wrench remove the hex head

7.

screw from both sides of the element. Remove ele-

ments from the element housing and replace with the

new elements.

Reassemble in the reverse order as above.

8.

CAUTION:

When re-installing covers and panels, be

sure the wires are guided and tucked into the proper open-

ings along the right side so they are not pinched and allows

enough space to reinstall panel.

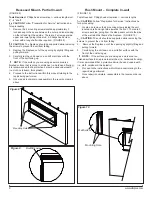

HIgH TEMPERATURE CUTOUT

REPLACEMENT

Tools required:

Phillips head screw driver

Needle nosed pliers

Small cutter or snips

CAUTION:

Follow “Preparation for Service” instructions

before proceeding.

Remove the 4 screws that secure the angled switch

1.

housing cover located just below the manual control

switches on the top right. Remove cover and set aside.

Remove the panel that spans across the top front facia.

2.

To do so, locate 4 screws, (2) on the left and (2) right

on the angled part behind the facia. Wires from the

switch housing are connected to this piece so carefully

move it farther down in the body of the unit, to give

some room to access the heater assembly cover.

Remove the heater assembly cover in the top center by

3.

removing the 10 screws on the side brackets, (5) on the

left and (5) on the right. Wires from the switch housing

are also connected to this piece, so carefully move it

farther down in the body of the unit, to give some room

to access the heater assembly housing.

Release the top panel of the heater assembly hous-

4.

ing by removing 2 screws on the side brackets, (1) left

and (1) right. Pull the top panel of the heater assembly

housing out from between the brackets.

Locate the temperature limit switch and remove the

5.

mounting screw.

Disconnect the wiring connections noting their original

6.