11

locations Pliers may be required for grip when discon-

necting the wire/spade connectors.

Cut and remove plastic cable tie that hold the wires in

7.

place on the top of the panel.

Properly orientate the new temperature limit switch and

8.

connect all of the wiring connections.

Reassemble in the reverse order as above.

9.

BLOWER/FAN ASSEMBLY

REPLACEMENT

Tools required:

Phillips head screw driver.

Needle nosed pliers.

CAUTION:

Follow “Preparation for Service” instructions

before proceeding.

Remove the 4 screws that secure the angled switch

1.

housing cover located just below the manual control

switches on the top right. Remove cover and set aside.

Remove the panel that spans across the top front facia.

2.

To do so, locate 4 screws, (2) on the left and (2) right

on the angled part behind the facia. Wires from the

switch housing are connected to this piece so carefully

move it farther down in the body of the unit, to give

some room to access the heater assembly cover.

Remove the heater assembly cover in the top center by

3.

removing the 10 screws on the side brackets, (5) on the

left and (5) on the right. Wires from the switch housing

are also connected to this piece, so carefully move it

farther down in the body of the unit, to give some room

to access the heater assembly housing.

Release the top panel of the heater assembly hous-

4.

ing by removing 2 screws on the side brackets, (1) left

and (1) right. Pull the top panel of the heater assembly

housing out from between the brackets.

From the top panel of the heater assembly housing, lo

-

5.

cate and remove the 6 screws that hold the blower/fan

assembly to the housing panel. Separate the blower

assembly from the housing panel.

CAUTION:

When removing the blower assembly

mounting screws support the assembly to prevent any

damage to the unit.

Disconnect the wiring connections noting their original

6.

locations. Pliers may be required for grip when discon-

necting the wire/spade connectors.

Properly orientate the new blower assembly and con-

7.

nect all of the wiring connections.

Reassemble in the reverse order as above.

8.

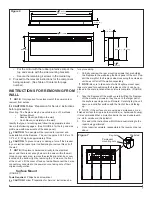

MAIN POWER SWITCH REPLACEMENT

Tools required:

Phillips head screw driver.

Needle nosed pliers.

CAUTION:

Follow “Preparation for Service” instructions

before proceeding.

Remove the 4 screws that secure the angled switch

1.

housing cover located just below the manual control

switches on the top right. Remove cover and set aside.

Remove the panel that spans across the top front facia.

2.

To do so, locate 4 screws, (2) on the left and (2) right

on the angled part behind the facia. Wires from the

switch housing are connected to this piece so carefully

rotate it up 180 degrees and move it farther down in the

body of the unit, to give some room for access. This

will make the switch visible from behind.

Note original locations of the switch wires and pull them

3.

off the switch prongs. Pliers may be required for grip

when disconnecting the wire/spade connectors.

Using needle nose pliers, pinch the tabs on either side

4.

of the switch to release and push the switch forward

out of the front of the panel. Note the orientation of the

switch prior to removing.

From the front of the panel, insert new switch by push

-

5.

ing switch back through the hole past the side tabs on

the switch, securing it in the opening.

Reconnect wires onto the prongs at the back of the

6.

switch in their original configuration.

Reassemble in the reverse order as above.

7.

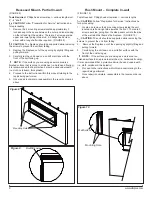

3-POSITION SWITCH BOARD

REPLACEMENT

Tools required:

Phillips head screw driver.

Needle nosed pliers.

Small cutter or snips

CAUTION:

Follow “Preparation for Service” instructions

before proceeding.

Remove the 4 screws that secure the angled switch

1.

housing cover located just below the manual control

switches on the top right. Remove cover and set aside.

Remove the panel that spans across the top front facia.

2.

To do so, locate 4 screws, (2) on the left and (2) right

on the angled part behind the facia. Wires from the

switch housing are connected to this piece so carefully

rotate it up 180 degrees and move it farther down in the

body of the unit, to give some room for access. This

will make the switch visible from behind.

Note original location and orientation of the switch

3.

wires attached to a Molex plug and pull them off the

switch board on the back right side of that facia panel.

To remove the board off the plastic mounts, cut or pinch

4.

the plastic mounting tabs with snips or needle nose pli-

ers. Pull the old board off.

Push the old mounts out towards the front/top of the fa-

5.

cia panel. Insert and push the new mounts all the way

through into the same opening. Line up the holes on

the circuit board and gently press the new board onto

the mounts. Make sure the board is secure.

Reconnect the Molex plug/wires onto the back of the

6.

switchboard in its original configuration. .

Reassemble in the reverse order as above.

7.