7

Put the mirror with the rubber protective strip at the

•

top and secure with the side mounting brackets

Secure the remaining 4 screws in the media tray.

•

Proceed to the relevant instructions for the component

9.

being replaced. (See Table of Contents for page

number).

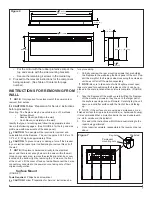

INSTRUCTIONS FOR REMOVINg FROM

WALL

!

NOTE:

Only required for replacement of the power cord or

removal from service.

CAUTION:

Follow “Preparation for Service” instructions

before proceeding.

Mounting - The fireplace may be mounted in one of 3 methods:

Surface Mount

•

Recess Mount (partially in the wall)

•

Flush Mount (completely in the wall)

•

Identify the type of mounting and follow the appropriate instruc-

tions in the following pages. (See FIGURE 6 for the top and side

profile view with measurents of the back panel).

CAUTION:

Two people will be required for removal and

re-installation of the fireplace. The unit is approx. 50 5/16”w x 19

1/2”h x 7”d. Weight is approximately 75lbs.

CAUTION:

To prevent injury or damage, turn off the breaker

in your electrical panel prior to attempting to remove this unit off

the wall.

!

NOTE:

If fireplace is hardwired directly to the electrical

panel, and there is not enough slack in the wires within the wall

to reach your work area, remove the electrical junction box cover

located on the bottom right by removing the 1 screw on the front

of the cover. Lift the cover off and set aside.Disconnect the 2 wire

connectors connected to the power source, taking note of their

original configuration.

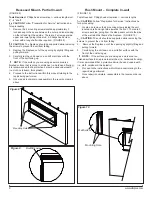

Surface Mount

(FIGURE 7)

Tools Required:

Philips head screwdriver

CAUTION:

Follow “Preparation for Service” instructions be

-

fore proceeding.

Partially unscrew the rear mounting screws that are holding

1.

the fireplace to the wall along the back panel of the unit. Sup

-

port the weight of the fireplace when loosening the screws so

unit does not fall off the wall unexpectedly.

!

NOTE:

Be sure to take note of which keyhole mount open-

ings were used for positioning the fireplace so that it can be re-

placed in the same location when service is complete. (FIGURE

7)

Take the fireplace off the wall by carefully lifting the fireplace

2.

off the mounting screws so they line up to the larger part of

the keyhole openings and pull forward. Carefully lay the unit

down on a solid flat surface with the front of the unit facing

up.

!

NOTE: If the surface you are using as a work area on is a

finished surface that is prone to scratches (i.e. hardwood flooring),

it is recommended that a protective barrier be used underneath,

(i.e. cloth, cardboard, thick plastic).

Proceed to the instructions within this manual relating to the

3.

repair being performed.

Once repair is complete, reassemble in the reverse order as

4.

above.

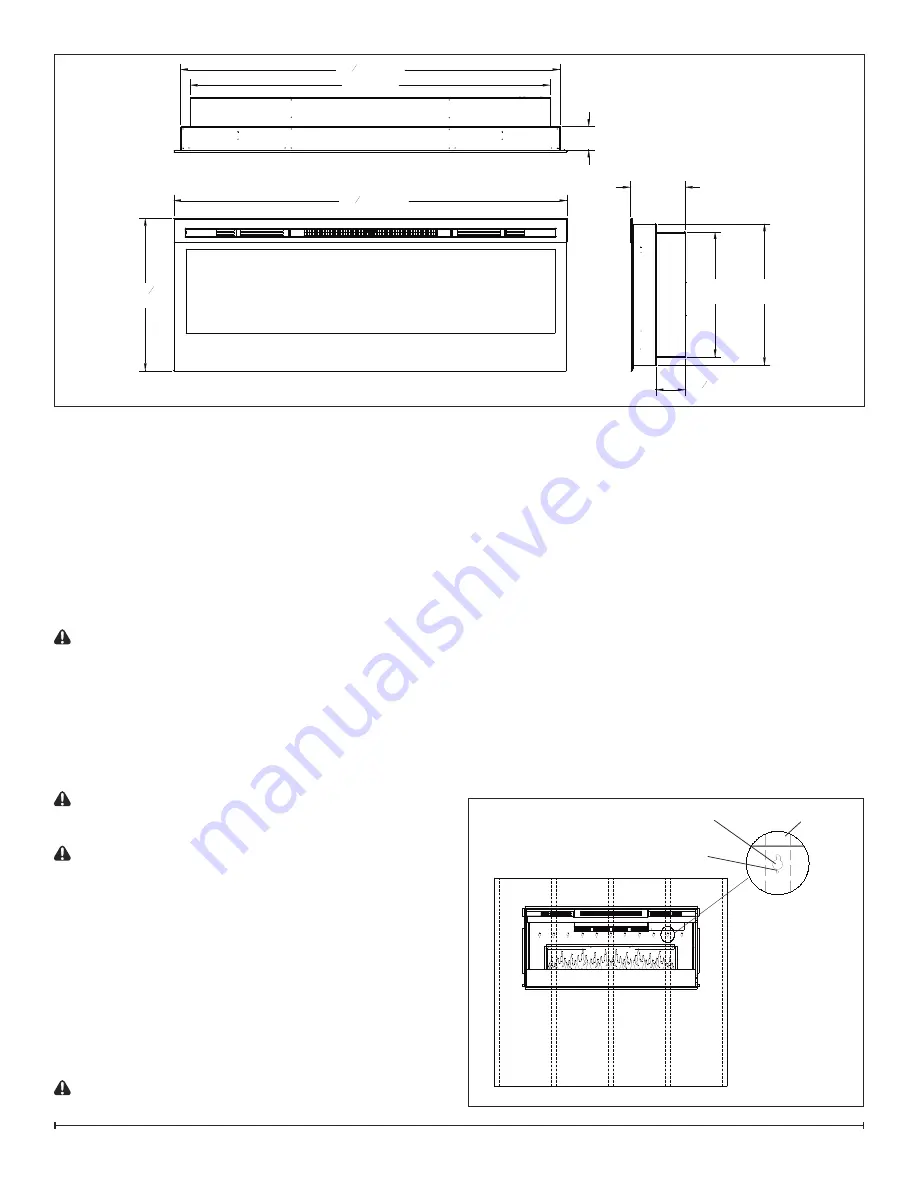

50

5

16

" (128 cm)

19

1

2

(49.5 cm)

46" (116 cm)

48

1

2

" (123 cm)

3" (7.6 cm)

7"

(17.8 cm)

3

13

16

"

(9.7 cm)

18"

(45.7 cm)

16"

(40.6 cm)

Figure 6

Figure 7

Key-hole

Wall stud

Permanent

mounting hole