11

GLASS MEDIA ASSEMBLY AND

PARTIALLY REFLECTIVE PANEL

REPLACEMENT

Tools Required:

Phillips Head Screwdriver

CAUTION:

If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING:

Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2.

Remove the firebox from the back of the mantel by

removing the retaining screws which secure the firebox

brackets to the mantel.

3. Remove the three screws along the back of the unit

and the two on either side along the bottom edge.

(Figure 6)

4.

Lay the Compact Fireplace on its back.

5. Gently open the bottom panel, laying it on the work sur-

face so that all of the components can easily be seen.

(Figure 7)

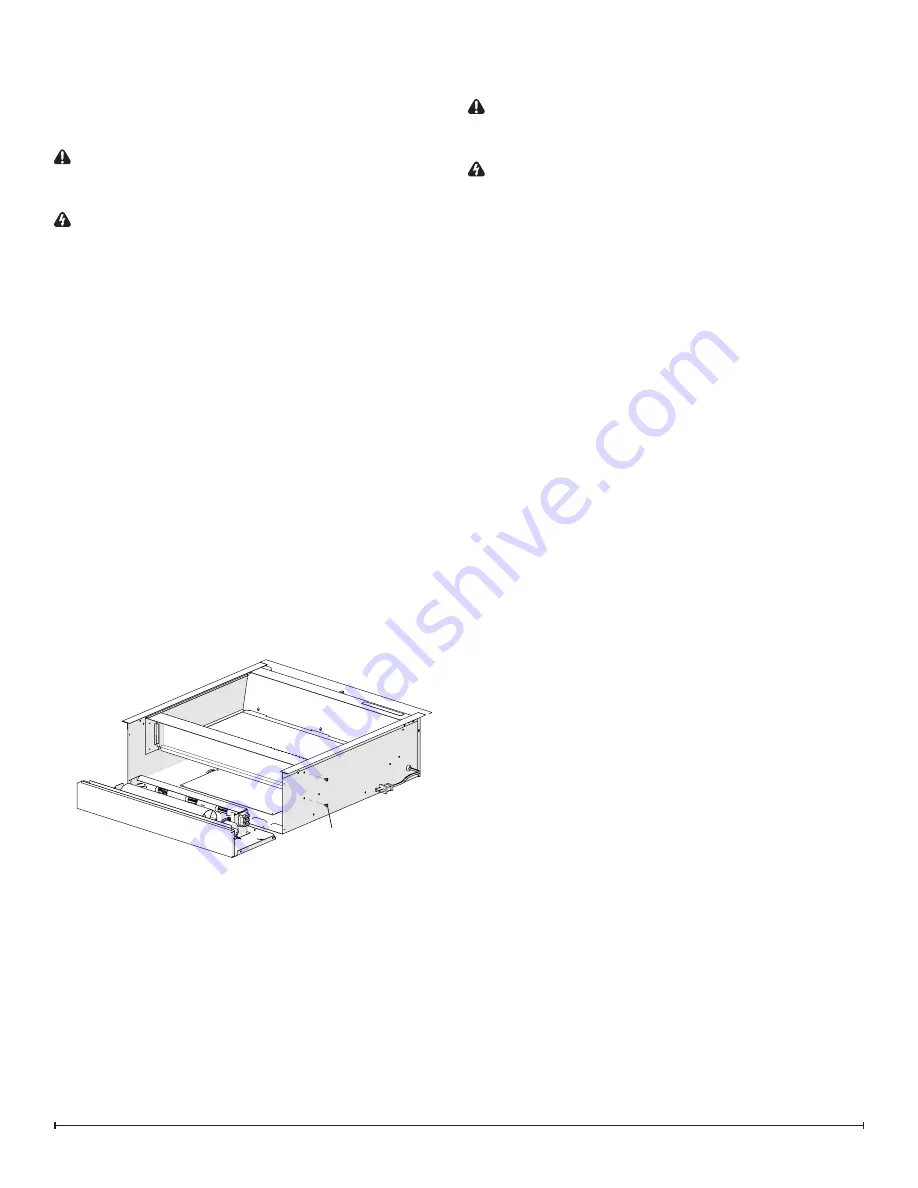

6. Remove the two screws on each side that secure the

glass media support brackets to the firebox. (Figure 9)

7. Remove the glass media and the support bracket.

8.

If required remove the partially reflective panel by slid

-

ing it out of the side channels towards the bottom.

9. Reassemble in the reverse order as above.

THERMISTOR REPLACEMENT

Tools Required:

Phillips Head Screwdriver

CAUTION:

If unit was operating prior to servicing allow

at least 10 minutes for lights, heating elements and top

panel to cool off to avoid accidental burning of skin.

WARNING:

Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2.

Remove the firebox from the back of the mantel by

removing the retaining screws which secure the firebox

brackets to the mantel.

3. Remove the three screws along the back of the unit

and the two on either side along the bottom edge.

(Figure 6)

4.

Lay the Compact Fireplace on its back.

5. Gently open the bottom panel, laying it on the work sur-

face so that all of the components can easily be seen.

(Figure 7)

!

NOTE:

Steps 6-7 are only applicable for units with

Glass Media assemblies.

6. Remove the two screws on each side that secure the

glass media support brackets to the firebox. (Figure 9)

7. Remove the glass media and the support bracket.

!

NOTE:

Steps 9-11 are only applicable for units with

logset assemblies.

8. Remove the two screws that secure the front glass

retaining bracket to the unit. (Figure 5)

9. Remove the front glass and set aside in a safe place.

10. Remove the retaining screw in the front middle of the

grate.

11. Pull the front edge of the plastic Ember Bed or plastic

grate up and forward until the rear tab releases from

the ledge located at the bottom of the Partially Reflect

-

ive Panel. (Figure 8)

!

IMPORTANT: Only handle the Log Set by the Ember

Bed.

!

NOTE: Log Set fits tightly into firebox, some force may

be necessary to remove.

12.

Remove the partially reflective panel by sliding it out of

the side channels towards the bottom.

13. Locate and release the thermistor from the back panel

by using needle nose pliers to depress the tab on the

mounting standoffs and gently lift the board off.

14. There is one connection located on the display/control

board that may require the board to be removed. This

can be done by removing the two screws on the right

hand side of the unit to remove the display/control

board to remove the connection and replace it with the

new one.

15. Install the new thermistor.

16. Reassemble in the reverse order as above.

Figure 9

Support Bracket

Screws