EN-4

451903.66.17 · FD 9908

www.gdts.one

English

LWP 200E

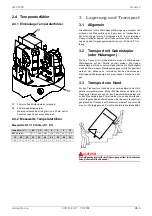

2.2 Refrigerant circuit (heat pump

operating principle)

The refrigerant circuit is a closed system in which the R134a re-

frigerant is the energy source. The finned heat exchanger ex-

tracts heat from the drawn-in air at a low evaporation tempera-

ture, and transfers it to the refrigerant. The vaporous refrigerant

is taken in by a compressor, where it is compressed to a higher

pressure and temperature level before being transported to the

liquefier, where the heat absorbed in the evaporator and part of

the compressing energy is transferred to the water. Subse-

quently, the high condensation pressure is lowered to the evapo-

ration pressure by a throttle mechanism (expansion valve), and

the refrigerant can again extract heat from the intake air in the

evaporator.

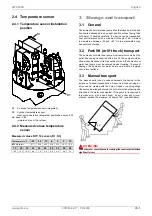

2.3 Safety and regulation devices

The domestic hot water heat pump is equipped with the following

safety devices:

High pressure switch (HP)

The high pressure switch protects the heat pump against unac-

ceptably high operating pressure in the refrigerant circuit, and

switches the heat pump off in the event of a fault. The heat pump

restarts automatically as soon as the pressure in the refrigerant

circuit has dropped again.

Safety temperature limiter for heating element

(STL)

The STL protects the domestic hot water system against unac-

ceptable temperature increases.

The heating element switches off if the set switching value

(99 °C) is exceeded.

The heating element cannot be switched on again until the hot

water temperature has decreased to

90 °C and the reset button

(see illustration) on the STL is pressed (this must only be done by

qualified personnel).

The domestic hot water heat pump is also equipped with the fol-

lowing regulation and control devices:

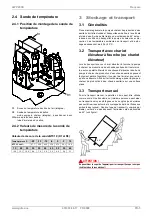

Heating element temperature controller (TC)

The heating element thermo controller regulates the hot water

temperature during heating element operation. The maximum

controller temperature is factory set to 65 °C (the controller and

the STL are installed together in a casing). Temperature settings

can be changed using suitable tools (see Fig. under 2.3).

Changes to this setting may only be carried out by qualified per-

sonnel.

In contrast to heat pump only operation, a smaller amount of

water is heated up to minimise the operating period of the heat-

ing element.

The heating element can be manually switched. In this operating

status, the domestic hot water is heated to the maximum temper-

ature of the heating element controller.

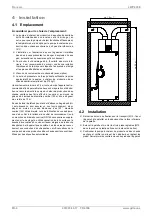

Heat pump temperature controller

Temperature control in the domestic hot water cylinder and the

regulation for compressor operation is carried out by the control

electronics. Electronic sensors measure the water temperature,

which is regulated based on the setpoint. The desired tempera-

ture level (setpoint) is set via the keypad on the control panel.

Air intake temperature

The sensor connected to the controller measures the tempera-

ture in the Domestic hot water heat pump directly in front of the

evaporator (air intake temperature). If the set switching value is

not reached (12 ±1.5 °C, reset value 2 K,

delay 30 min), the domestic hot water preparation is switched au-

tomatically from heat pump operation to heating element opera-

tion.

Partition

(in the device)

Reset button

STL

85°

30°

B5

F17