www.glendimplex.de

DOK4x HOIAO FxDEN · FD 0001

11

Air-to-water heat pump M Flex

English

6 Assembly / connection

6.1 Assembly of the refrigerant line

and electric wire

The refrigerant lines and electric wires for connecting the in-

door unit with the outdoor unit must be ordered separately as

accessories.

To route the connection wires, create wall openings at suitable

points. The wall opening must be protected from water pene-

tration according to the local conditions.

The wall openings should be sealed again correctly once the

routing work is complete. (For connecting the electric wire, see

cap. 6.6 on page 14, for connecting the refrigerant line, see

cap. 6.8 on page 19).

6.2 Condensate drain

Condensate that forms during operation must be drained off

frost free. To ensure proper drainage, the outdoor unit must be

mounted horizontally.

The condensate tray offers various options for the condensate

drain:

Foundation covered with gravel. The leaching should be

min. 1.5 l per kW of heat output per day, and the diameter

of the drain pipe should be at least 50 mm.

Channel into a waste water, rain water or drainage channel

If the condensate drain is installed at risk from frost, it must be

protected from freezing with a condensate drain heater, which

is available as a special accessory.

The connection takes place in the outdoor unit and must take

place in accordance with the electrical documentation.

HINWEIS

ºº

º

ºº

º

NOTE

The frost line can vary according to the climatic region. The

regulations of the countries in question must be observed.

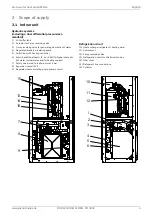

6.3 Connection on heating side

Before connecting the heating system to the heat pump, the

heating system must be flushed to remove any impurities, resi-

due from sealants, etc. Any accumulation of deposits in the liq-

uefier may cause the heat pump to completely break down.

A purging option must be arranged directly upstream and

downstream of the indoor unit.

Once the heat pump has been connected to the heating sys-

tem, it must be filled, purged and pressure-tested.

When doing so, it must be ensured that all heating circuits and

isolating valves are open and that the 3-way reversing valve is in

heating operation (pos. 1 factory default). Fill the heating sys-

tem at the fill and drain cock (pos. 2) until system pressure (ap-

prox. 1.5 bar) is reached. A suitable fill hose with a pressure

gauge should be used. When doing so, check all connections

and the entire heating system for leakages. The heating system

should be purged at the highest point (pos. 3, e.g. radiator, heat

pumps connection).

After all of the air has been purged, the indoor unit must be

purged on the domestic hot water cylinder (if present), on the

electric auxiliary heating (pos. 4), buffer tank (pos. 5), dirt filter

(pos. 6) and plate heat exchanger (pos. 7) until the heating

water also exits free of bubbles here.

If the power supply is connected, the reversing valve can be

switched for more effective purging on the touch display in the

installer level under Service and Analytics

Control functions

pumps. The generator pump M16 can also be activated for ad-

ditional support.

Finally, close the fill and drain cock, check the system pressure

and top up if necessary.

3

3

3

3

2

4

5

1

6

7

Summary of Contents for M Flex Air

Page 2: ......

Page 37: ...www glendimplex de DOK4x HOIAO FxDEN FD 0001 35 Air to water heat pump M Flex English...

Page 38: ...36 DOK4x HOIAO FxDEN FD 0001 www glendimplex de English Air to water heat pump M Flex...

Page 39: ...www glendimplex de DOK4x HOIAO FxDEN FD 0001 37 Air to water heat pump M Flex English...