www.glendimplex.de

DOK4x HOIAO FxDEN · FD 0001

19

Air-to-water heat pump M Flex

English

6.8 Refrigerant pipe connections

!!

ATTENTION!

Work on the system must only be performed by authorised

and qualified after-sales service technicians.

Certain requirements with regard to pipe length and rise must

be complied with when installing refrigerant pipes. Once all

conditions are met, the connection of the connecting pipe from

the outdoor unit to the indoor unit can begin.

6.8.1 Requirements for the pipe length

and rise

The indoor unit of the heat pump is already filled with refriger-

ant. The standard pipe length is 3.0 m. Up to a length of 7 m, no

additional refrigerant filling is required. For pipe lengths over

7 m, the system must be filled with additional refrigerant in ac-

cordance with the table.

!!

ATTENTION!

Incorrect filling with refrigerant could lead to faults during op-

eration.

!!

ATTENTION!

The length of the refrigerant line is calculated based on the

total line length from the respective connection point of the

indoor unit to the outdoor unit.

Incorrect refrigerant filling or refrigerant lines over 10 m result

in a risk of faults during operation and a complete failure of

the heat pump.

*Example: When installing the 9 kW model at a distance of

10 m, 420 g refrigerant must be added according to the follow-

ing calculation: (10 - 7) x 140 g = 420 g

HINWEIS

ºº

º

ºº

º

NOTE

If the indoor unit is mounted 2.5 m or more metres higher or

lower than the outdoor unit, a cooling technology specialist

must perform a separate check to ensure that the devices for

conveying the oil up and down the pipes have been installed

correctly in the exhaust gas pipe. The maximum rise (B) be-

tween the indoor and outdoor units is 5 m.

HINWEIS

ºº

º

ºº

º

NOTE

The specified operating data of the device refers to the stand-

ard pipe length, see device information.

6.8.2 Pipe connection

The connection points for the refrigerant lines must be estab-

lished using the brazing process. All generally applicable instal-

lation and work steps must be followed for this. The reducing

sleeves provided must be used for connecting the outdoor unit

in the M Flex 0609 version.

During the brazing process, the pipe system must be flushed

with an inert gas (e.g. nitrogen). The adjacent components must

be suitably cooled to prevent them being damaged.

6.8.3 Leak test and evacuation

Air and moisture in the cooling system have unwanted effects

as outlined below.

1) The pressure in the system increases.

2) The operating current increases.

3) The cooling (or heating) output falls.

4) Moisture in the cooling circuit can freeze and block the

capillary tubes.

5) Water can cause corrosion on parts in the cooling

system.

This means that the connection pipes must be checked for

leaks and pumped empty to remove any moisture and non con-

densable gases from the system.

Step 1: Preparation

Ensure that every pipe (liquid and intake side) between the in-

door and outdoor unit is connected correctly. Ensure that both

maintenance valves on the liquid and intake of the indoor unit

are closed at this point.

Step 2: Leakage tightness test

Connect a dry nitrogen gas cylinder (with Schrader) on the

maintenance valve.

Apply 40 bar dry nitrogen to the system. Close the cylinder

valve once the test pressure is reached. The next step is to

search for leaks with liquid soap.

HINWEIS

ºº

º

ºº

º

NOTE

In order to prevent liquid nitrogen from entering the cooling

system, the top side of the gas cylinder must be higher than

the bottom side when pressure is building in the system.

All pipe connections (internal and external) must be

checked for leaks with liquid soap. Bubbles indicate a leak.

The soap must then be wiped away with a clean cloth.

If no leaks are found on the system, drain off the nitrogen.

Model

Pipe size (mm)

(external

diameter x wall

thickness)

Length A (m)

*additional

refrigerant

(g/m)

Gas

Liquid

Normal Min. Max.

M Flex 0609

12 x 1

10 x 1

7

3

10

75

M Flex 0916M

18 x 1

12 x 1

7

3

10

140

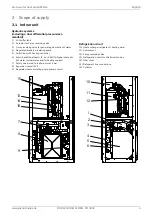

Outdoor unit

Indoor unit

A

B

Outdoor unit

Indoor unit

A

B

max. 5 m

max. 5 m

Summary of Contents for M Flex Air

Page 2: ......

Page 37: ...www glendimplex de DOK4x HOIAO FxDEN FD 0001 35 Air to water heat pump M Flex English...

Page 38: ...36 DOK4x HOIAO FxDEN FD 0001 www glendimplex de English Air to water heat pump M Flex...

Page 39: ...www glendimplex de DOK4x HOIAO FxDEN FD 0001 37 Air to water heat pump M Flex English...