10

www.dimplex.com

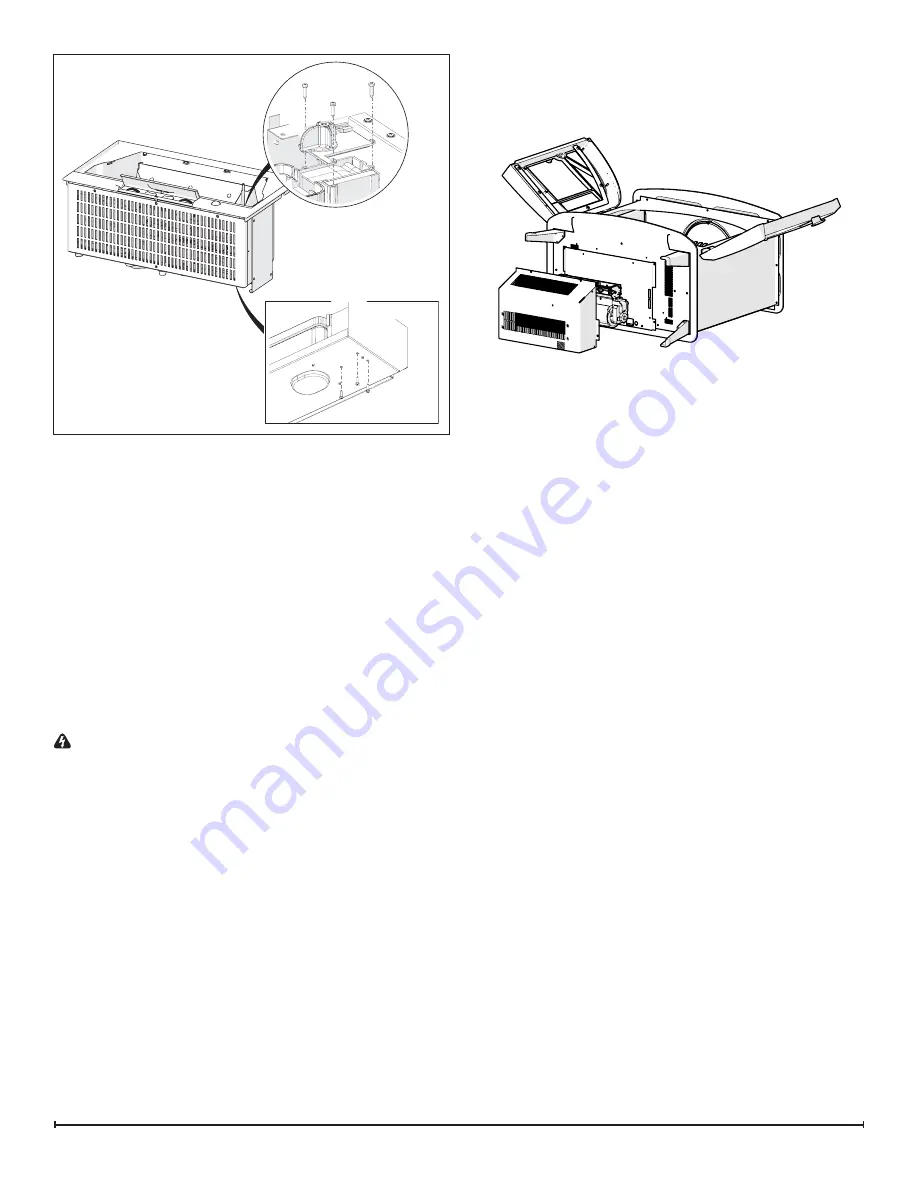

Figure 6

semble the remainder of the cassette in revers order

from the instructions above.

• If replacing the housing, remove the 3 screws attaching

the base to the cassette. (Figure 6)

8. Attach new fan housing base to the cassette.

9. Transfer the filter from the old housing to the new hous-

ing.

10. Reinstall the fan motor and reconnect the wire.

11. Re-assemble the remainder of the cassette in reverse

order from the instructions above.

HEATER ASSEMBLY REPLACEMENT

Tools Required:

Phillips head screwdriver

Flat head screwdriver

WARNING:

Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

!

NOTE:

Ensure that all of the components that

contain water have been emptied before performing any

maintenance.

1. Disconnect and remove the log set from the unit and

put it in a safe place.

2. Lay the unit on it’s back to access the heater assembly

area.

3. Remove the 4 screws that secure the assembly to the

stove. (Figure 7)

4. Allow the assembly to separate from the stove by gen-

tly pulling the cord out of the opening in the bottom of

the stove.

5. Remove the 2 screws on the top of the assembly, 2 on

the bottom on either side and 2 on either side of the

heater outlet.

6. Set the top panel up against the bottom of the stove.

Figure 7

7. On the bottom of the heater assembly remove the 4

screws around the inlet of the heater, to release the

heater assembly.

8. Slide the heater assembly backwards to remove it out

of the assembly.

9. Transfer the wiring connections from the old assembly

to the new assembly.

!

NOTE:

A flat head screwdriver can be used to gently

pry between the end of the connector and the switch to

release the wires.

10. Slide the heater assembly back into the assembly and

re-assemble the remainder of the cassette in reverse

order from the instructions above.