We recommend cleaning the following components once every 2 weeks, particularly in hard water areas:-

Water Tank, Sump, Nozzle, Tank cap and seal, Air filter.

For general cleaning use a soft clean duster – never use abrasive cleaners.

To remove any accumulation of dust or fluff, the soft brush attachment of a vacuum cleaner should occasionally be

used.

Water tank

1. Remove water tank, as described earlier, put into sink and empty water.

2. Using the supplied brush gently rub the inside surfaces of the cap paying particular attention to the rubber ring in

the outer groove and the centre rubber seal.

3. Put a small quantity of washing up liquid into the tank, refit the cap and shake well, rinse out until all traces of

washing up liquid are gone.

4. Refill with filtered tap water only, replace the cap, do not overtighten.

Sump

1. Press Switch ‘A’ to the ‘OFF’

(0)

position

2. Gently lift out the fuelbed and place carefully on the ground.

3. Remove the water tank by lifting upwards.

4. Disconnect the electrical connector, located on the right side of the sump. (See Fig.5) .

5. Release the right sump locking tabs by turning 90º. This allows the sump to be lifted completely from its location.

6. Gently lift up the sump, taking care to keep level so as not to spill any water. Sit the assembly in the sink.

7. Release the left sump locking tabs by turning 90º, then lift off the Nozzle. (See Fig.3)

8. Lift out the transducer and carefully tilt, as shown, so that the liquid drains out of the sump. (See Fig.13)

9. Put a small amount of washing up liquid into the sump, and using the supplied brush, gently clean all surfaces in the

sump and gently clean the transducer including the metal discs located in the top grooved surface. (See Fig.14)

10. When cleaned, thoroughly rinse the sump with clean water to remove all traces of washing up liquid.

11. Clean the Nozzle with the brush and flush out thoroughly with water. (See Fig.15)

12. Reverse the above steps to reassemble.

Air filter

1. Gently lift out the fuelbed and place carefully on the ground.

2. Gently slide the air filter upwards out of its plastic holder. (See Fig.16)

3. Gently rinse with water in the sink and dry with fabric towel before returning.

4. Replace the filter making sure that the coarse black filter is facing the front of the fire.

5. Replace the fuelbed.

Summary of Contents for RND020

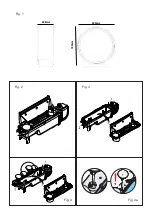

Page 2: ...Fig 1 Fig 4 Fig 4a Fig 2 Fig 3 650mm 288mm 700mm...

Page 3: ...Fig 5 Fig 5a Fig 5b Fig 6 Fig 7 Fig 8...

Page 4: ...Fig 9 Fig 10 Fig 11 Fig 12 2 3...

Page 5: ...REMOTE CONTROL SENSOR Fig 15 Fig 16 Fig 17 Fig 13 Fig 14...

Page 12: ......

Page 13: ......