8

www.dimplex.com

Accessing Top Components

Tools Required:

Phillips head screwdriver

WARNING:

If the firebox was operating prior to

servicing, allow at least 10 minutes for the heating

elements to cool off to avoid accidental burning of skin.

WARNING:

Disconnect power before attempting any

maintenance to reduce the risk of electric shock or injury

to persons.

1. Unhook the front glass to remove it by pulling it up

slightly and pulling it out. Set it aside in a safe place.

2. Remove the firebox from the mantel by removing the

retaining screws that secure the firebox to the mantel.

These may be located on the inside of the firebox near

the front, or behind the firebox if it is secured with L-

brackets.

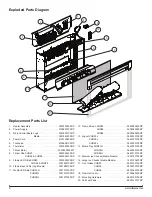

3. Unfasten the top panel by removing the 12 screws lo

-

cated around the periphery of the top panel. There are

2 screws on each side, 3 on the back, and 5 at the very

top, directly behind the front flange. Some units may

have 6 screws on the top, totaling 13 screws. (Figure 1)

4. Slide the top panel toward the back to release it.

5. Carefully lay the firebox on its back and lay the top

cover flat so that the attached components are acces

-

sible.

Accessing Bottom components

Tools Required:

Phillips head screwdriver

WARNING:

If the firebox was operating prior to

servicing, allow at least 10 minutes for the heating

elements to cool off to avoid accidental burning of skin.

WARNING:

Disconnect power before attempting any

maintenance to reduce the risk of electric shock or injury

to persons.

1. Unhook the front glass to remove it by pulling it up

slightly and pulling it out. Set it aside in a safe place.

2. Remove the firebox from the mantel by removing the

retaining screws that secure the firebox to the mantel.

These may be located on the inside of the firebox

near the front, or behind the firebox if it is secured with

L-brackets.

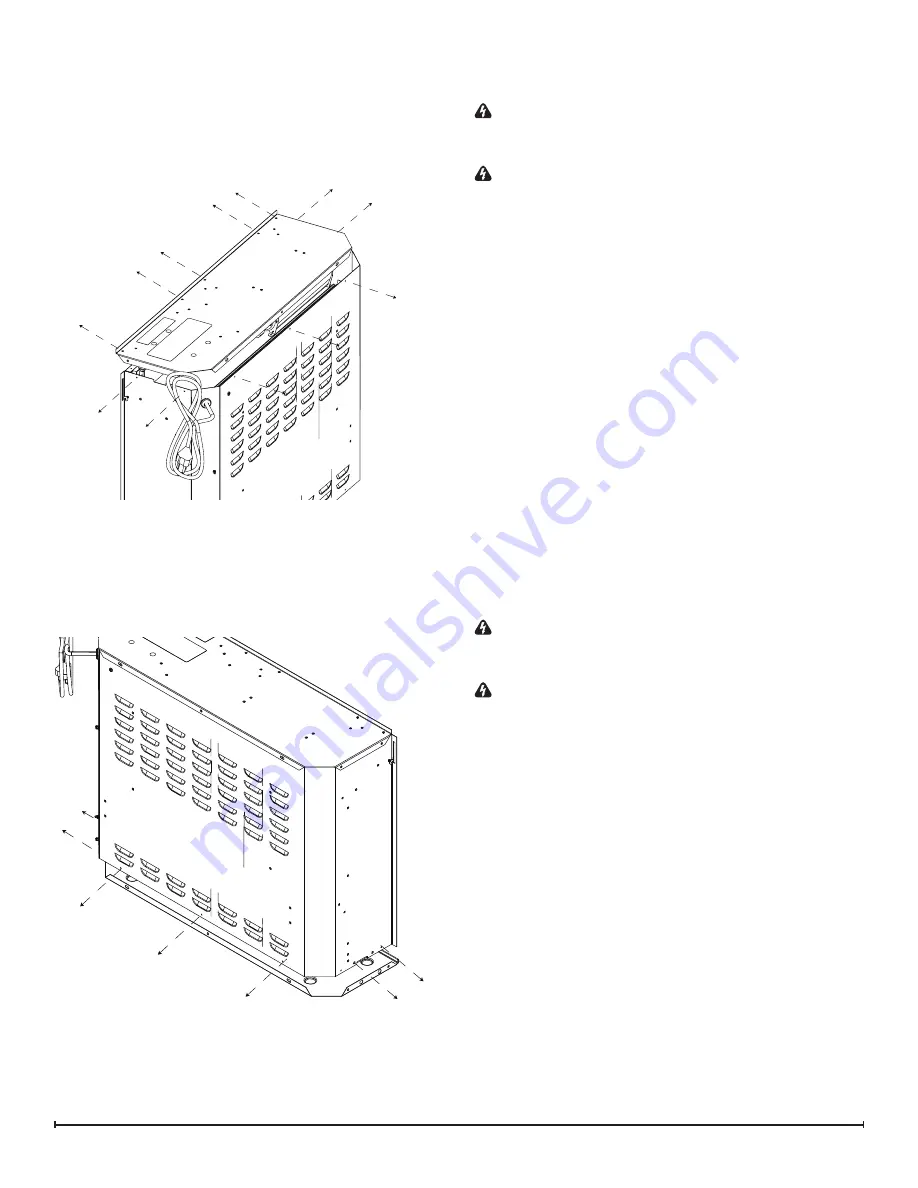

3. Unfasten the bottom panel by removing the 11 screws

located on the back and sides of the bottom panel.

There are 3 screws on the back, and 4 screws on each

side. Note that the two middle screws on each side

are longer, and hold the media tray or log set in place.

(Figure 2)

!

NOTE:

When reinstalling the base panel, align the

2 middle screw holes on each side of the logset/media

tray with the corresponding holes on the base panel

to ensure that the logset or media tray are properly af

-

fixed. (Figure 4)

Figure 1

Figure 2