Instruction manual DNDS Kompakt

Products: safety

technique

DNDS KOMPAKT

Version 04 / 2011.03.16

page 7 from 20

Circuit diagram

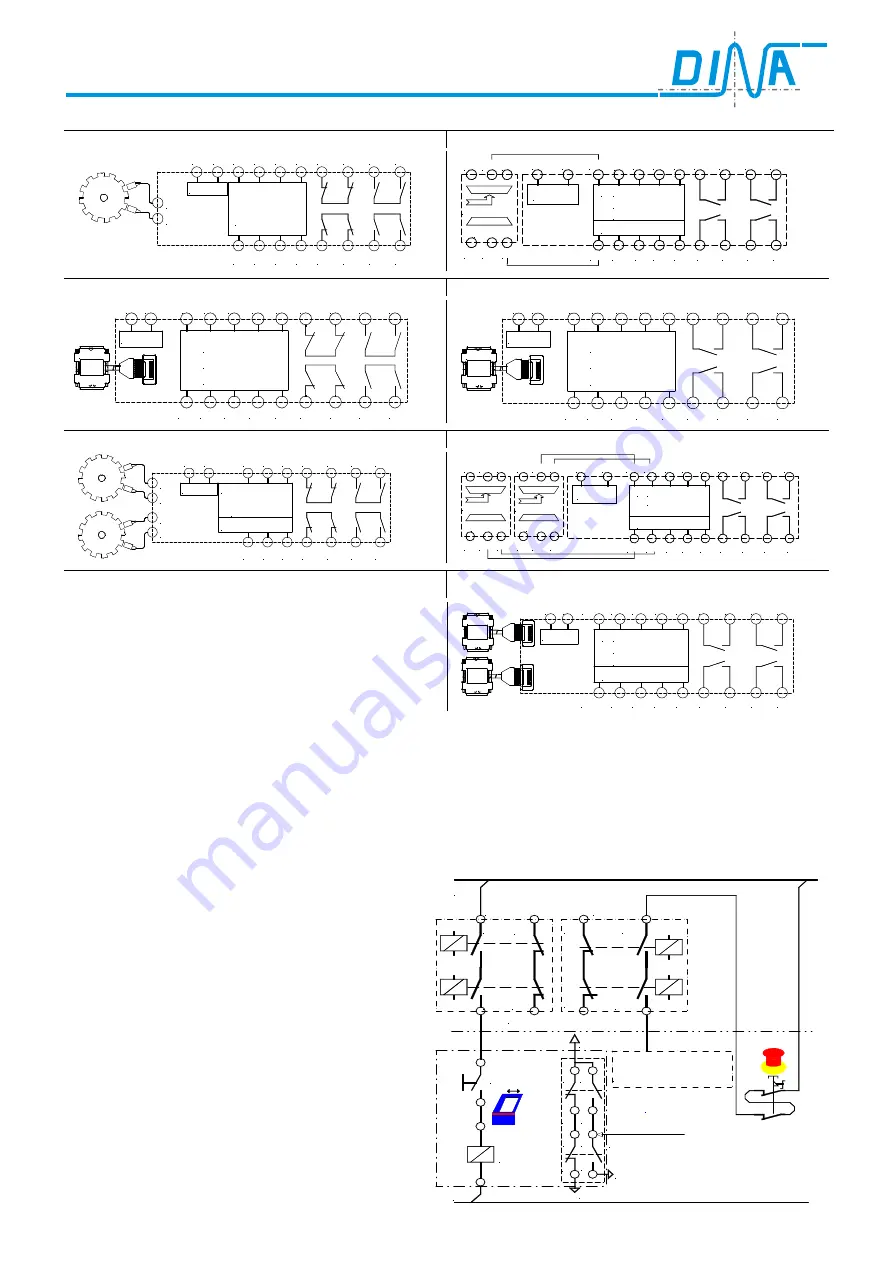

DNDS1C

Motion detection:

proximity sensors

DNDS 1D

Motion detection:

encoder

24VDC

Überwachung

Monitoring

Surveillance

A1 A2

F2 F3 F4 11 12 13 14

D2 D3 D4 21 22 23 24

IN1

IN2

F1

D1

24VDC

Surveillance

A1

A2

F1

13 14 23 24

33 34 43 44

IN1

Überwachung

Monitoring

1.

2.

F2 F3 F4

D1

IN2

D2 D3 D4

A1

A1 IA1

IA1

IA2

IA2

DNDA --/15

DNIA

DNDS 1FA

Motion detection:

encoder

DNDS 1GA

Motion detection:

encoder

24VDC

Surveillance

A1 A2

F1 F2 F3 F4 11

R

Überwachung

Monitoring

D1 D2 D3 D4

SH

12

13

14

21

22

23

24

Encoder

Meßsystem

24VDC

Surveillance

A1 A2

F1 F2 F3 F4 13

R

Überwachung

Monitoring

D1 D2 D3 D4

SH

14

23

24

33

34

43

44

Encoder

Meßsystem

DNDS 2C

Motion detection:

proximity sensors

DNDS 2D

Motion detection:

encoder

24VDC

Überwachung

Monitoring

Surveillance

A1 A2

IN1

D1 D2 D3 11 12 13 14

D4 D5 D6 21 22 23 24

IN2

IN3

IN4

1.

2.

DNIA

DNDA --/15

IA1

IA1

A1

A1

IA2

IA2

24VDC

Surveillance

A1

A2

IN2

13 14 23 24

33 34 43 44

IN1

Überwachung

Monitoring

1.

2.

D1 D2 D3

IN4

IN3

D4 D5 D6

A1

A1 IA1

IA1

IA2

IA2

DNDA --/15

DNIA

DNDS 2GA

Bewegungserfassung:

Encoder

Motion detection:

encoder

24VDC

Surveillance

A1 A2

D11 D12 D13 D14 13

SH11

Überwachung

Monitoring

1.

2.

D21 D22 D23 D24

SH21

14

23

24

33

34

43

44

Encoder

Meßsystem

Encoder

Meßsystem

DNDS 1C, 1FA, 2C, 2FA:

Applications of the outputs

STOP contacts: Standstill monitoring

If the protection cover is closed and one or more drives are in movement, the NO-contacts

13-14

open immediate-

ly. The NC-contacts

11-12

close. The LED STOP is not illuminated. The protection cover cannot be opened.

If all drives are stopped the contacts 13-14 close and 11-12 close. The protection cover can be opened. The LED

STOP is illuminated.

SPEED contacts: Motion monitoring

If the protection cover is closed, the F-inputs and

respectively the D-inputs of DNDS will be connected

to 24V DC via the switch of the protection cover. The

automatic mode will be monitored.

In case of the protection cover is open DNDS moni-

tors the standstill of all drives, if there is no function

mode selected.

If there is some function mode selected, as example

tool setting via SH-, R-input of DNDS, this function

mode will be monitored.

If one or more drives break the standstill as well as

the adjusted speed of the function mode, the NO

contacts

23-24

open and

21-22

close immediately.

The LED SPEED does not illuminated.

The drives will be stopped by emergency stop circuit

(STOP category 0). See principal schematic.

The contacts 23-24 close and 21-22 open again, if

the actual speed is 10% lower than the adjusted

speed. The LED SPEED illuminates.

Emergency stop

circuit

24

23

22

21

11

12

13

14

STOP

SPEED

L1

L2

to unlock

cover

Magnets

for bolt

DNDS

DNDS F- or D-inputs

Quit

Protection cover

switch

11 13

12 14

21 23

22 24

24V DC

CNC

Information contacts

Summary of Contents for DNDS 1C

Page 20: ......