CLM–36

©

Dinel, s.r.o.

11

8 . e

lectrical

connection

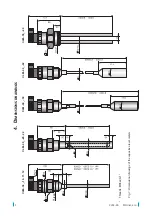

The level meter is designed to be connected to supply unit or to controller through a cable with the

outer diameter of 6 ÷ 8 mm (recommended cross-section of cores 0.5 ÷ 0.75 mm

2

) by means of

connector which is included in delivery. The scheme and the inside of the connector are on pictures.

Procedure to connect the cable to the level

meter:

1.

Unscrew connector from the body of the level

meter using a suitable screwdriver.

2.

Use a flat screwdriver to remove the inner

part of the connector (screwdriver into the

gap marked by arrow).

3.

Unscrew the cable gland and put the cable

inside.

4. Connect the cable wires to the screw termi-

nals as shown in Fig. 10 (current output 4-20

mA) or Fig. 12 (voltage output 0-10 V). Tigh-

ten the terminals firmly.

5. Push the terminals back into the connector so

that the terminal no. 3 is oriented toward the

cable entry. Tighten the cable gland.

6. Check the seal on the connector and connect

the connector back to the body of the sensor.

Electrical connection must be done in de-energized state!

The voltage source should be preferably realized as a stabilized power supply unit with safe voltage from

18 to 36 V DC (18

÷

30 V DC at version Xi(XiT)), which can be a part of the evaluation or display device.

In case of strong electromagnetic interferences (EMI), parallel cable ducting with power lines, or when

cable length exceeds 30 m we recommended to use shielded cable.

Fig. 9: Connection scheme with current

output

Shielding

(Green-Yellow)

+U (

Brown

)

0V (

Blue

)

Fig. 10: Connection scheme with

current output

U

out

(

Black

)

+U (

Brown

)

Shielding

(Green-Yellow)

0V (

Blue

)

Fig. 11: Connection scheme with voltage

output

Fig. 12: Connection scheme with

voltage output

Summary of Contents for CLM-36

Page 2: ......

Page 27: ...26 Dinel s r o CLM 36...