CLM–70

©

Dinel, s.r.o.

8

BASIC INFO

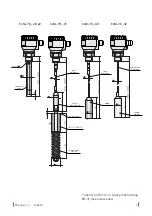

• The level meters with an insulated electrode are equipped with a protective cap at the

electrode end, which must be removed before installation.

•

The level meters are mounted vertically into the upper lid of the tank or hopper or on fixing

brackets using a welding flange for a fixing nut or a Clamp-type flange.

• When installing the level meter in a metal tank or hopper, the housing is not necessary to

be grounded separately.

• In the case of installation in concrete sumps or silos, the level meter is advisable to

be installed on an auxiliary metal structure (bracket, lid, etc.) and then connected to

a permanently submerged metal object or steel reinforcements in concrete (armouring).

E - electrode length [mm] –

select so that the electrode

end is submerged at least

20 mm below the lowest

measured level

h - distance from the bottom

– at least 50 mm

a - distance from the wall – at

least approx. E/20

d - diameter of the auxiliary

tubular vessel – at least 40

+ E/20 (smaller dimensions

must be discussed)

Auxiliary electrode

width = minimum

30 mm

(required for non-

metal vessels only)

Fig. 1: Installation of level meters with rod electrodes

6 .

i

nstallation

and

pUtting

into

operation

This procedure has the following three steps:

• i

nstallation

instrUCtions

• e

leCtriCal

ConneCtion

• s

ettings

7 .

i

nstallation

instrUCtions

METAL AND NON-METAL VESSELS

APPLIES TO: CLM-70_-10, 11, 12, 13

Summary of Contents for CLM-70

Page 2: ......