DLM–35

©

Dinel, s.r.o.

3

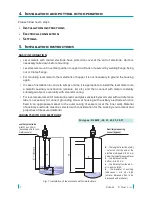

The capacitative level meters DLM

®

are intended for continuous level measurement of liquid

and bulk solids in tanks, vessels, sumps or silos, hoppers etc. They are comprised of a housing

with electronic module and measuring electrodes. The electronic part converts the size of the

capacity to the current signal (4 ... 20 mA) or voltage signal (0 ... 10 V).Level meters are made

in several modifications of measuring electrodes (rod and rope). The electrodes can be covered

by an insulating coating in case level measurement of adhesive, aggressive or electrically

conductive media. Rod electrodes are also available in a version with reference (coaxial) tube for

level measurement of liquids in tanks made from non-conductive material.

Level meters are produced in the following performances:

N

– for non-explosive areas,

NT

– high temperature for non-explosive areas,

Xi

– Explosion proof – intrinsically safe for hazard-

ous (explosive) areas and

XiM

– Explosion proof – intrinsically safe for use in mines with methane

or flammable dust presence danger (see technical specifications). There are high temperature per-

formance

NT, XiT, XiMT

available. DLM are offered in variants with various types of process con-

nection (metric and pipe thread, pressure thread NPT).

1 . Basic description

To ensure maximum safety of control processes, we have defined the following safety instructions

and information. Each instruction is labelled with the appropriate pictogram.

Alert, warning, danger

This symbol informs you about particularly important instructions for installation and operation of

equipment or dangerous situations that may occur during the installation and operation. Not observing

these instructions may cause disturbance, damage or destruction of equipment or may cause injury.

Information

This symbol indicates particularly important characteristics of the device.

Note

This symbol indicates helpful additional information.

Used symbols

Safety

All operations described in this instruction manual have to be carried out by trained personnel

or by an accredited person only. Warranty and post warranty service must be exclusively

carried out by the manufacturer.

Improper use, installation or set-up of the sensor can lead to crashes in the application.

The manufacturer is not responsible for improper use, loss of work caused by either direct

or indirect damage, and for expenses incurred at the time of installation or during the period

of use of the level sensors.