9

©

Dinel, s.r.o. UL_–53

•

The ultrasonic signal can be scattered or attenuated if the

surface is moderately stirred or rippled (due to a mixer, inflow

of liquid, etc.). This may result in

reduction of the measure-

ment range

or unreliable operation of the device (Fig. 11).

For a rippled or swirling level, you can use the directional

horn to eliminate scattering of the ultrasonic signal.

!

Fig. 11: Moderately stirred surface

•

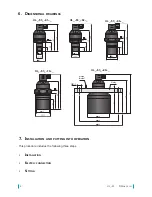

The site for installing the level meter needs to be chosen so that the emitted acoustic signal is not

affected by

nearby objects

(reinforcements, supports, brackets, ladders, heating elements, mixers,

etc.). These obstacles may result in false rebounds, increasing measurement inaccuracy (Fig. 9).

x – distance from the edge of the longest

object

c – maximum reach of the level meter

UL_–53–01 ;02 ; 10

x > c/12

(min. 200 mm)

UL_–53–06

x > c/8

(min. 200 mm)

UL_–53–20

x > c/10

(min. 200 mm)

Fig. 9: Minimum distance from close objects in the tank

•

Foam may be produced on the surface of the measured liquid

during filling, mixing and other processes. The thick foam

significantly absorbs the ultrasound signal and may cause

malfunction of the device (Fig.10). In those cases it is neces-

sary to test the device in advance or contact the manufacturer .

In case of a thin layer of foam, it is also possible to use

directional horn for improving receipt of the reflected echo.

!

Fig. 10: Thick foam on the surface

!

Fig. 12: Strongly stirred

surface

Fig. 13: False reflection from

mixer blades

•

The device should not be installed in places

with the risk of

false reflections

of the ultra-

sonic signal from the mixer’s blades (Fig. 13).

• False surface reflections of the ultrasonic

signal and unreliable operation of the device

might result from the mixer’s

rotating blades

that ripple the surface level(Fig. 12).

Summary of Contents for ULM-53 series

Page 2: ......

Page 27: ...27 Dinel s r o UL_ 53 ...