9

©

Dinel, s.r.o. ULM–53L

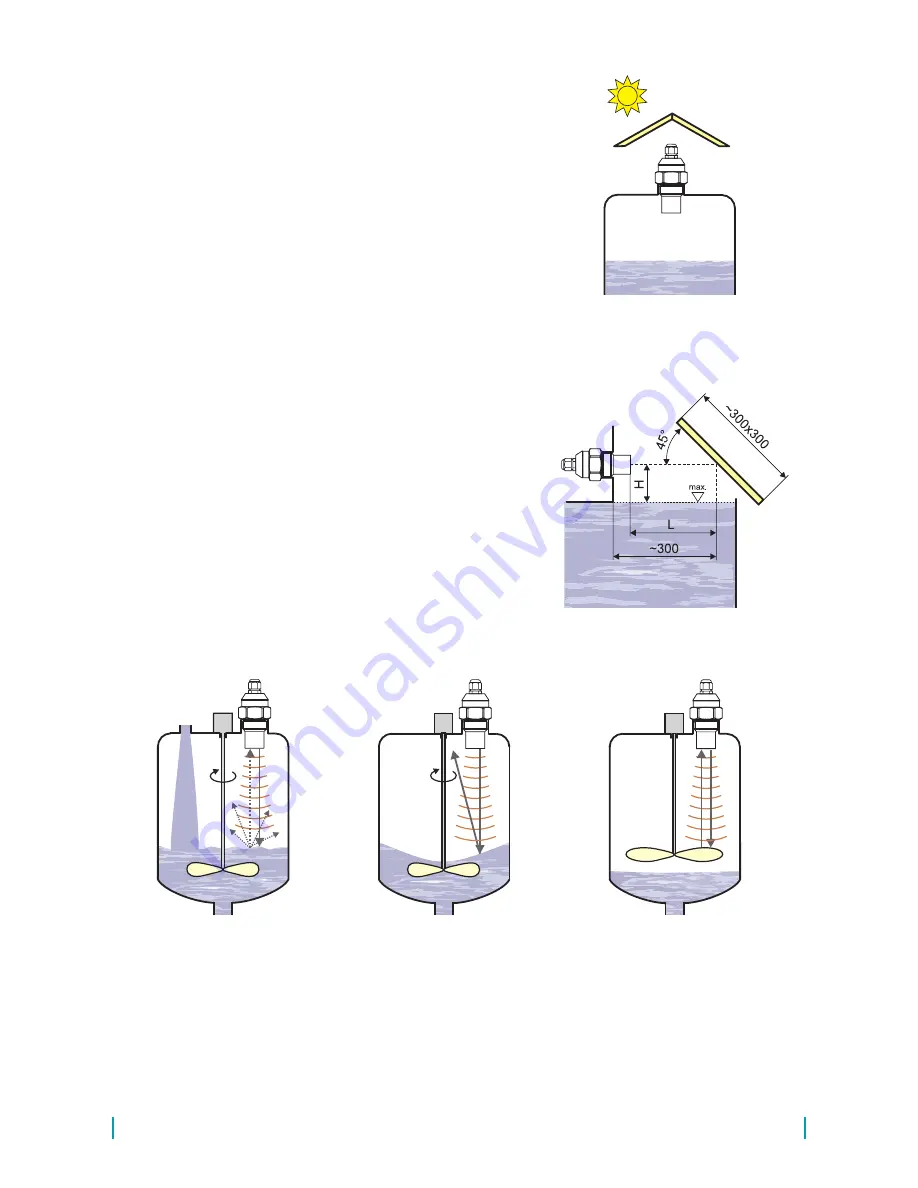

Fig. 9:

Reflection board

H + L = Dead zone

Fig. 11: Intensely stirred

surface

!

Fig. 8: Direct solar radiation shielding

cover

k) The level meter must

not be installed

in places

with direct solar radiation and must be protected

against weather conditions.

l) In case the installation at places with direct solar

radiation is inevitable, it is necessary to mount

a

shielding cover

above the level meter (Fig. 8).

m) To lower the minimum distance to the medium meas

-

ured, a

reflection board

made from solid, even and

smooth material can be installed together with the

level meter (Fig. 10). Subsequently, the tank can be

filled nearly up to the maximum volume. The solution

is suitable for open tanks and reservoirs.

n) Scattering or attenuation of the ultrasonic signal can

result if the surface level has been moderately stirred

or rippled as a consequence a stirrer’s operation,

inflow of liquid and the like. Consequently, measuring

range or unreliable level meter’s functioning

might

follow

(Fig. 11).

o) False surface reflections of the ultrasonic signal

might result as a consequence of

rotating mixer’s

blades

that ripple the surface level and thus cause

unreliable level meter’s functioning (Fig. 12).

p) The level meter should not be installed at places

where ultrasonic signal

false reflections

caused

by stirrer blades might occur (Fig. 13).

!

Fig. 10: Moderately stirred

surface

Fig. 12:

False reflection caused by

mixer blade