【

1-8

】

GENERAL INFORMATION

Fuel,

Oil

and

Engine

Coolant

Recommendation

Fuel

(For

USA

and

Canada)

●

Use

only

unleaded

gasoline

of

at

least

87

pump

octane

(R/2

+

M/2)

or

95

octane

or

higher

rated

by

the

Research

Method.

●

Gasoline

containing

MTBE

(Methyl

Tertiary

Butyl

Ether),

less

than

10%

ethanol,

or

less

than

5

%

methanol

with

appropriate

cosolvents

and

corrosion

inhibitor

is

permissible.

Fuel

(For

Other

Countries)

●

Gasoline

used

should

be

graded

95

octane

(Research

Method)

or

higher.

An

unleaded

gasoline

is

recommended.

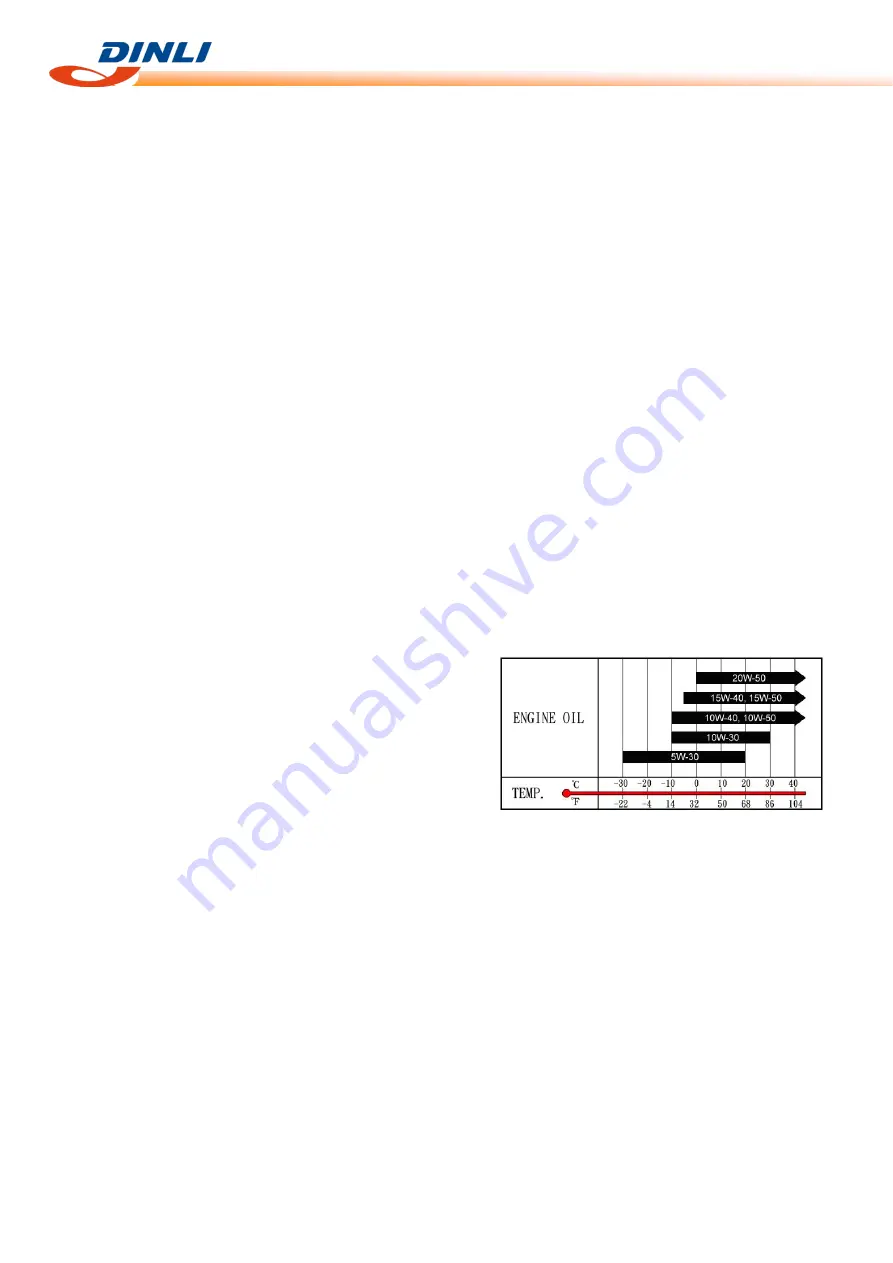

Engine

Oil

(For

USA)

●

Dinli

recommends

the

oil

which

is

rated

SF

or

SG

under

the

API(American

Petroleum

Institute)

service

classification.

The

recommended

viscosity

is

SAE

10W

‐

40.

If

SAE

10W

‐

40

oil

is

not

available,

select

an

alternative

according

to

the

following

chart.

Engine

Oil

(For

Other

Countries)

●

Use

a

premium

quality

4

‐

stroke

motor

oil

to

ensure

longer

service

life

of

your

vehicle.

Use

only

oil

which

are

rated

SF

or

SG

under

the

API

service

classification.

The

recommended

viscosity

is

SAE

10W

‐

40.

If

SAE

10W

‐

40

motor

oil

is

not

available,

select

an

alternative

according

to

the

right

chart.

Front

Differential

Gear

Oil

●

Use

hypoid

gear

oil

that

meets

the

API

service

classification

GL

‐

5

and

is

rated

SAE

#80W

‐

90.

Rear

Gear

(Final)

Box

Oil

●

Use

hypoid

gear

oil

that

meets

the

API

service

classification

GL

‐

5

and

is

rated

SAE

#80W

‐

90.

Summary of Contents for DL-702 2008

Page 1: ...FOREWORD INDEX 0 0...

Page 41: ...3 11 BRAKE...

Page 180: ...6 70 ENGINE Install the starter motor...

Page 201: ...7 21 COOLING AND LUBRICATION SYSTEM Engine Lubrication System Chart...

Page 202: ...7 22 COOLING AND LUBRICATION SYSTEM Engine Lubrication System 1 2 3 1 2 3 1 2 3...

Page 203: ...7 23 COOLING AND LUBRICATION SYSTEM 1 2 3...

Page 235: ...7 32 ELECTRICAL SYSTEM Wiring Diagram...

Page 236: ...7 33 ELECTRICAL SYSTEM Wiring Diagram...

Page 237: ...7 34 7 34 ELECTRICAL SYSTEM ELECTRICAL SYSTEM...

Page 238: ...7 35 ELECTRICAL SYSTEM NOTE...

Page 240: ...9 2 PERIODIC MAINTENANCE...

Page 246: ...9 8 PERIODIC MAINTENANCE Intake Side...

Page 247: ...9 9 PERIODIC MAINTENANCE Exhaust Side Side...

Page 270: ...9 32 PERIODIC MAINTENANCE 1 2 3 4 18 19 12 16 17 21 13 14 15 22 23 5 6 7 8 9 12 10 11 20...