【

6-24

】

ENGINE

●

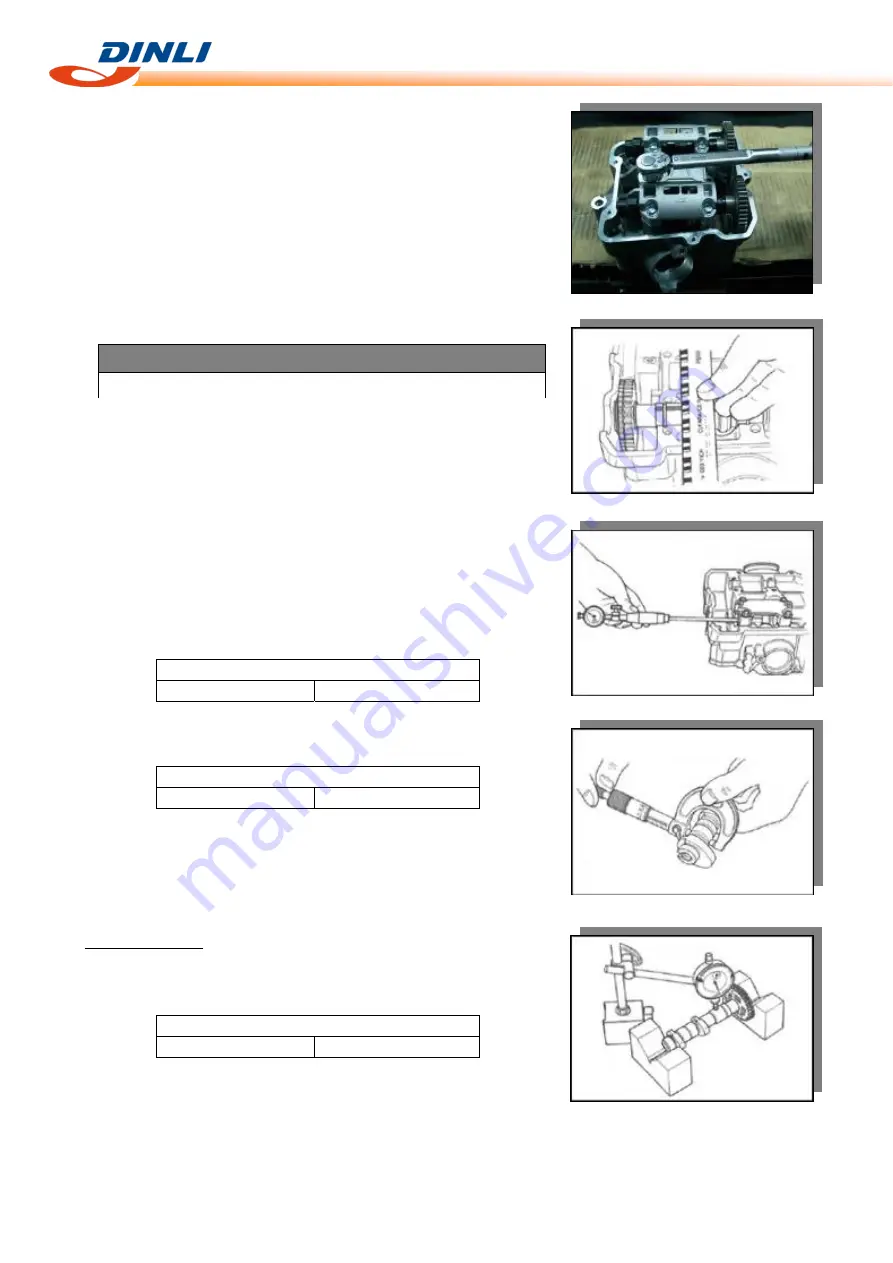

Tighten

the

camshaft

journal

holder

bolts

evenly

and

diagonally

to

the

specified

torque.

Tightening

Torque:

10N

‐

m

(1.0

kgf

‐

m,

7.0

lb

‐

ft)

NOTE

Do

not

rotate

the

camshaft

with

the

plastigauge

in

place.

●

Remove

the

camshaft

holders,

and

read

the

width

of

the

compressed

plastigauge

with

envelope

scale.

●

This

measurement

should

be

taken

at

the

widest

part.

●

If

the

camshaft

journal

oil

clearance

measured

exceeds

the

limit,

measure

the

inside

diameter

of

the

camshaft

journal

holder

and

outside

diameter

of

the

camshaft

journal.

●

Replace

the

camshaft

or

the

cylinder

head

depending

upon

which

one

exceeds

the

specification.

ID

of

cam

journal

portion

Standard

(IN

&

EX)

23.000

‐

23.021

mm

Small

Bore

Gauge

(18

–

35

mm)

Dial

Gauge

(1/1000

mm,

1

mm)

OD

of

Camshaft

journal

portion

Standard

(IN

&

EX)

22.959

‐

22.980

mm

Micrometer

Camshaft

Runout

●

Measure

the

runout

from

using

the

dial

gauge.

●

Replace

the

camshaft

if

the

runout

exceeds

the

limit.

Service

Limit

Of

Camshaft

Runout

IN

&

EX

0.10

mm

Dial

Gauge

(1/1000

mm,

10

mm)

Magnetic

Stand

V

‐

block

Set

(100

mm)

Summary of Contents for DL-702 2008

Page 1: ...FOREWORD INDEX 0 0...

Page 41: ...3 11 BRAKE...

Page 180: ...6 70 ENGINE Install the starter motor...

Page 201: ...7 21 COOLING AND LUBRICATION SYSTEM Engine Lubrication System Chart...

Page 202: ...7 22 COOLING AND LUBRICATION SYSTEM Engine Lubrication System 1 2 3 1 2 3 1 2 3...

Page 203: ...7 23 COOLING AND LUBRICATION SYSTEM 1 2 3...

Page 235: ...7 32 ELECTRICAL SYSTEM Wiring Diagram...

Page 236: ...7 33 ELECTRICAL SYSTEM Wiring Diagram...

Page 237: ...7 34 7 34 ELECTRICAL SYSTEM ELECTRICAL SYSTEM...

Page 238: ...7 35 ELECTRICAL SYSTEM NOTE...

Page 240: ...9 2 PERIODIC MAINTENANCE...

Page 246: ...9 8 PERIODIC MAINTENANCE Intake Side...

Page 247: ...9 9 PERIODIC MAINTENANCE Exhaust Side Side...

Page 270: ...9 32 PERIODIC MAINTENANCE 1 2 3 4 18 19 12 16 17 21 13 14 15 22 23 5 6 7 8 9 12 10 11 20...