ENGINE

【

6-27

】

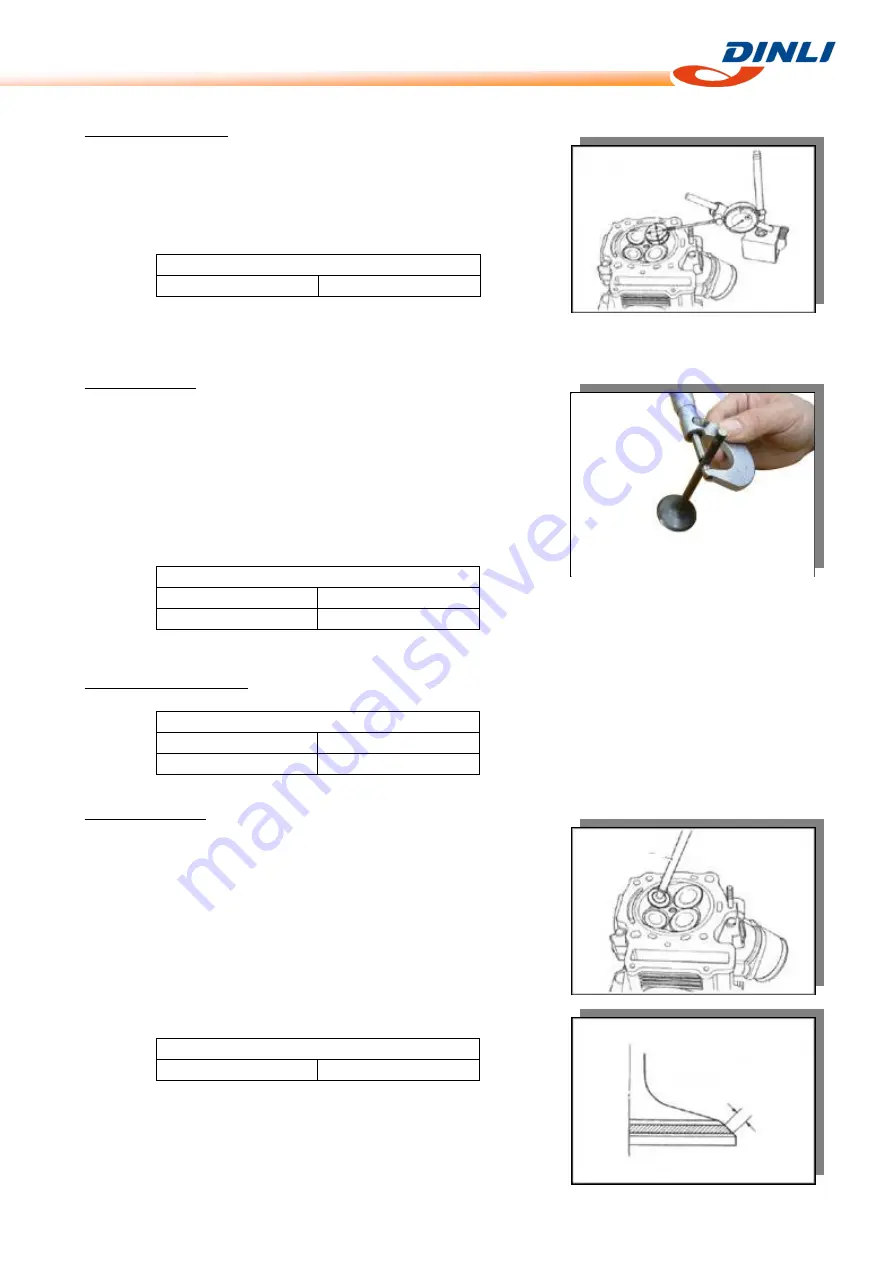

Valve

stem

deflection

●

Lift

the

valve

about

8

mm

from

the

valve

seat.

Measure

the

valve

stem

deflection

in

two

directions,

perpendicular

to

each

other,

by

positioning

the

dial

gauge.

●

If

the

deflection

measured

exceeds

the

limit,

then

determine

whether

the

valve

or

the

guide

should

be

replaces

with

a

new

one.

Service

Limit

of

Valve

stem

deflection

IN

&

EX

0.35

mm

Dial

Gauge

(1/100

mm)

Magnetic

Stand

Valve

stem

wear

●

If

the

valve

stem

is

worn

down

to

the

limit,

as

measured

with

a

micrometer,

where

the

clearance

is

found

to

be

in

excess

of

the

limit

indicated,

replace

the

valve;

if

the

stem

is

within

the

limit,

then

replace

the

guide.

●

Measure

OD

of

Valve

Stem

sliding

portion

at

total

6

points;

upper,

middle

and

lower

positions

and

X

‐

and

Y

‐

directions,

by

means

of

micrometer.

Service

Limit

of

Valve

Guide

OD

IN

5.450

‐

5.465

mm

EX

5.430

‐

5.445

mm

Micrometer

(0

–

25

mm)

Valve

Guide

Attachment

Valve

Guide

Attachment

Height

IN

12.7

mm

EX

12.5

mm

Valve

Seat

Width

●

Coat

the

valve

seat

uniformly

with

bright

color.

Fit

the

valve

and

tap

the

coated

seat

with

the

valve

face

in

a

rotating

manner,

in

order

to

obtain

a

clear

impression

of

the

seating

contact.

In

this

operation,

use

the

valve

lapper

to

hold

the

valve

head.

●

The

ring

like

dye

impression

left

on

the

valve

face

must

be

continuous

without

any

break.

In

addition,

the

width

of

the

dye

ring,

which

is

visualized

seat

“width”,

must

fit

the

specification.

Valve

Seat

Width

Standard

0.9

mm

–

1.1

mm

Valve

Lapper

Set

W

Summary of Contents for DL-702 2008

Page 1: ...FOREWORD INDEX 0 0...

Page 41: ...3 11 BRAKE...

Page 180: ...6 70 ENGINE Install the starter motor...

Page 201: ...7 21 COOLING AND LUBRICATION SYSTEM Engine Lubrication System Chart...

Page 202: ...7 22 COOLING AND LUBRICATION SYSTEM Engine Lubrication System 1 2 3 1 2 3 1 2 3...

Page 203: ...7 23 COOLING AND LUBRICATION SYSTEM 1 2 3...

Page 235: ...7 32 ELECTRICAL SYSTEM Wiring Diagram...

Page 236: ...7 33 ELECTRICAL SYSTEM Wiring Diagram...

Page 237: ...7 34 7 34 ELECTRICAL SYSTEM ELECTRICAL SYSTEM...

Page 238: ...7 35 ELECTRICAL SYSTEM NOTE...

Page 240: ...9 2 PERIODIC MAINTENANCE...

Page 246: ...9 8 PERIODIC MAINTENANCE Intake Side...

Page 247: ...9 9 PERIODIC MAINTENANCE Exhaust Side Side...

Page 270: ...9 32 PERIODIC MAINTENANCE 1 2 3 4 18 19 12 16 17 21 13 14 15 22 23 5 6 7 8 9 12 10 11 20...