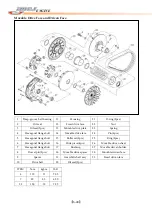

ENGINE

【

6-39

】

●

Apply

THREAD

LOCK

to

the

bolts.

●

Tighten

the

starter

clutch

bolts

to

the

specified

torque.

Tightening

Torque

:

26

N

‐

m

(2.6

kgf

‐

m,

19.0

lb

‐

ft)

●

Install

the

starter

driven

gear

to

the

starter

clutch.

●

Check

that

the

starter

driven

gear

is

in

the

opposite

direction

of

the

arrow

mark

[A]

on

the

rotor

while

holding

the

generator

motor.

The

gear

never

turns

in

the

direction

of

the

arrow.

●

If

there

is

anything

unusual,

replace

the

one

way

clutch.

●

Check

the

starter

driven

gear

bearing,

If

there

is

anything

unusual,

replacing

the

bearing.

●

Remove

the

bearing

with

the

special

tool.

●

Install

the

bearing

with

the

special

tool.

Oil

Gallery

Copper

Plug

●

Inspect

the

copper

plug

and

its

O

‐

ring.

If

any

damages

has

found

in

the

O

‐

ring,

replace

it

with

a

new

one.

CAUTION

If

the

O

‐

ring

does

not

changed

even

if

the

damages

are

found,

the

oil

pressure

will

be

too

low

to

run,

and

may

turns

on

the

oil

pressure

indicator.

Summary of Contents for DL-702 2008

Page 1: ...FOREWORD INDEX 0 0...

Page 41: ...3 11 BRAKE...

Page 180: ...6 70 ENGINE Install the starter motor...

Page 201: ...7 21 COOLING AND LUBRICATION SYSTEM Engine Lubrication System Chart...

Page 202: ...7 22 COOLING AND LUBRICATION SYSTEM Engine Lubrication System 1 2 3 1 2 3 1 2 3...

Page 203: ...7 23 COOLING AND LUBRICATION SYSTEM 1 2 3...

Page 235: ...7 32 ELECTRICAL SYSTEM Wiring Diagram...

Page 236: ...7 33 ELECTRICAL SYSTEM Wiring Diagram...

Page 237: ...7 34 7 34 ELECTRICAL SYSTEM ELECTRICAL SYSTEM...

Page 238: ...7 35 ELECTRICAL SYSTEM NOTE...

Page 240: ...9 2 PERIODIC MAINTENANCE...

Page 246: ...9 8 PERIODIC MAINTENANCE Intake Side...

Page 247: ...9 9 PERIODIC MAINTENANCE Exhaust Side Side...

Page 270: ...9 32 PERIODIC MAINTENANCE 1 2 3 4 18 19 12 16 17 21 13 14 15 22 23 5 6 7 8 9 12 10 11 20...