【

6-17

】

ENGINE

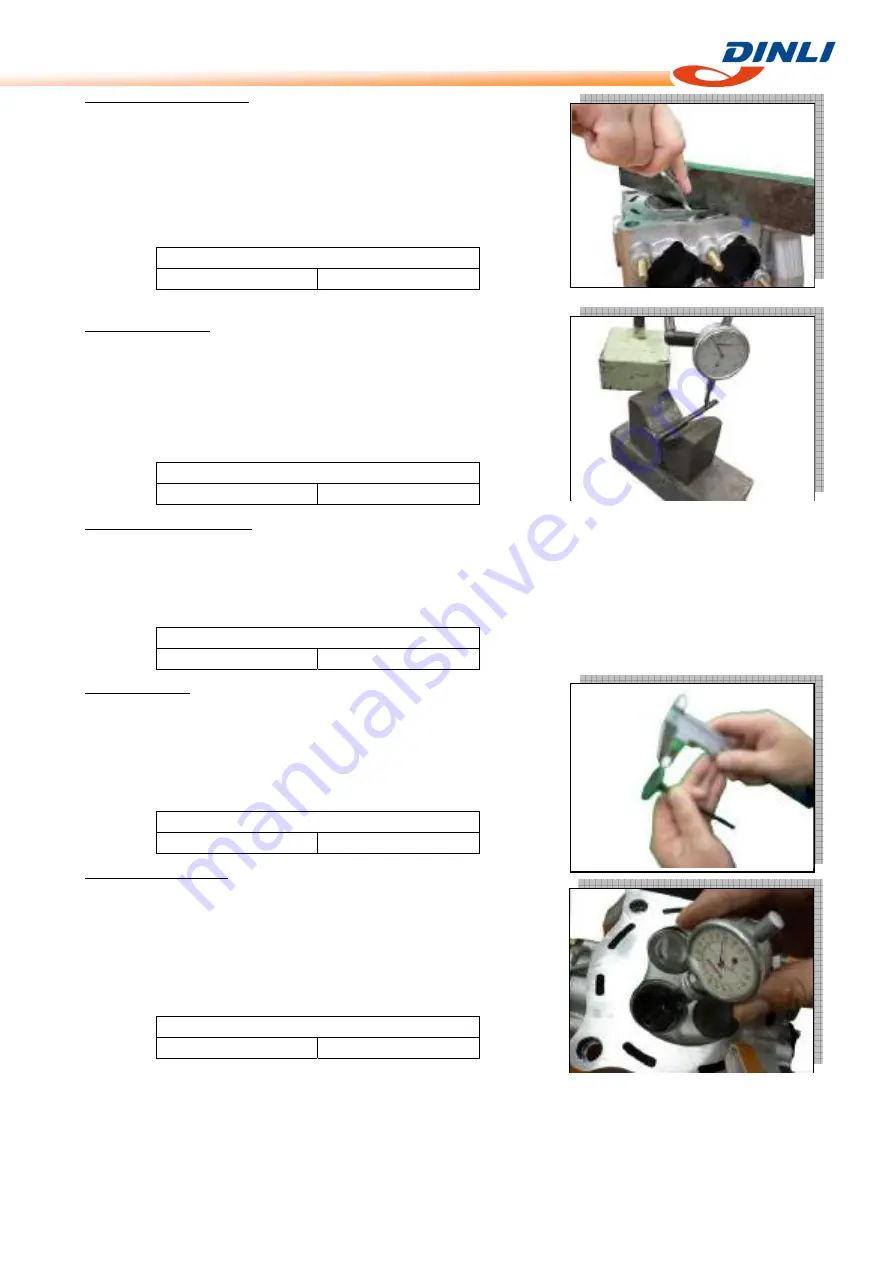

Cylinder head distortion

●

Clean and remove carbon deposits from the surface. Never damage

the surface when cleaning.

●

Place straight edge on the surface, and check with thickness gauge.

●

If the result is out of specifications, replace with new Cylinder

Head.

Cylinder Head Distortion

Service Limit

0.05 mm

Valve Stem runout

●

Remove carbon deposits.

Place on the V-block.

●

Measure the runout by means of dial gauge.

●

If the result is out of specifications, replace with new Valve.

Valve Stem runout

Service Limit

0.05 mm

Valve head radial runout

●

Place the dial gauge at right angles to the valve head face, and

measure the valve head radial runout.

●

If it measures more than the limit, replace the valve.

Service Limit of Valve head radial runout

IN & EX

0.03 mm

Valve face wear

●

Inspect each valve for wear of its seating face. Replace any valve

with an abnormally worn face.

●

Measure the thickness, and if it measures less than the limit, replace

the valve.

Service Limit of Valve head thickness

IN & EX

0.5 mm

Valve stem deflection

Lift the valve about 8mm from the valve seat. Measure the valve stem

deflection in two directions, perpendicular to each other, by

positioning the dial gauge.

If the deflection measured exceeds the limit, then determine whether

the valve or the guide should be replaces with a new one.

Service Limit of Valve stem deflection

IN & EX

0.35 mm

Summary of Contents for DL702

Page 1: ... 0 0 FOREWORD INDEX ...

Page 88: ... 7 13 ELECTRICAL SYSTEM Wiring Diagram ...

Page 89: ... 7 14 ELECTRICAL SYSTEM Wiring Diagram ...

Page 90: ... 7 15 ELECTRICAL SYSTEM NOTE ...