23

9. Annex

一

.

Nozzle Selection

Spraying the spray paint and the flow rate is determined by the nozzle, so choosing the

right nozzle is very important and appropriate spraying construction sites can enhance the

efficiency of the flow is appropriate to reduce unnecessary waste of paint, and vice versa

Ran.Generally speaking, the viscosity of the coating in the choice of spray nozzle and the

flow rate, an important subject, when used by the lower viscosity of the coating, we usually

recommend the use of spray flow rate narrower and smaller nozzle Conversely, if coating

viscosity higher or solid components in a higher viscosity, we would recommend that you

use a wide spray and the rate of flow to the larger atomizing nozzle coatings, in the table

below is different coating viscosity we recommended by the nozzle aperture size.

!!

notice

!!

Do not use more than the support of equipment nozzle

diameter.

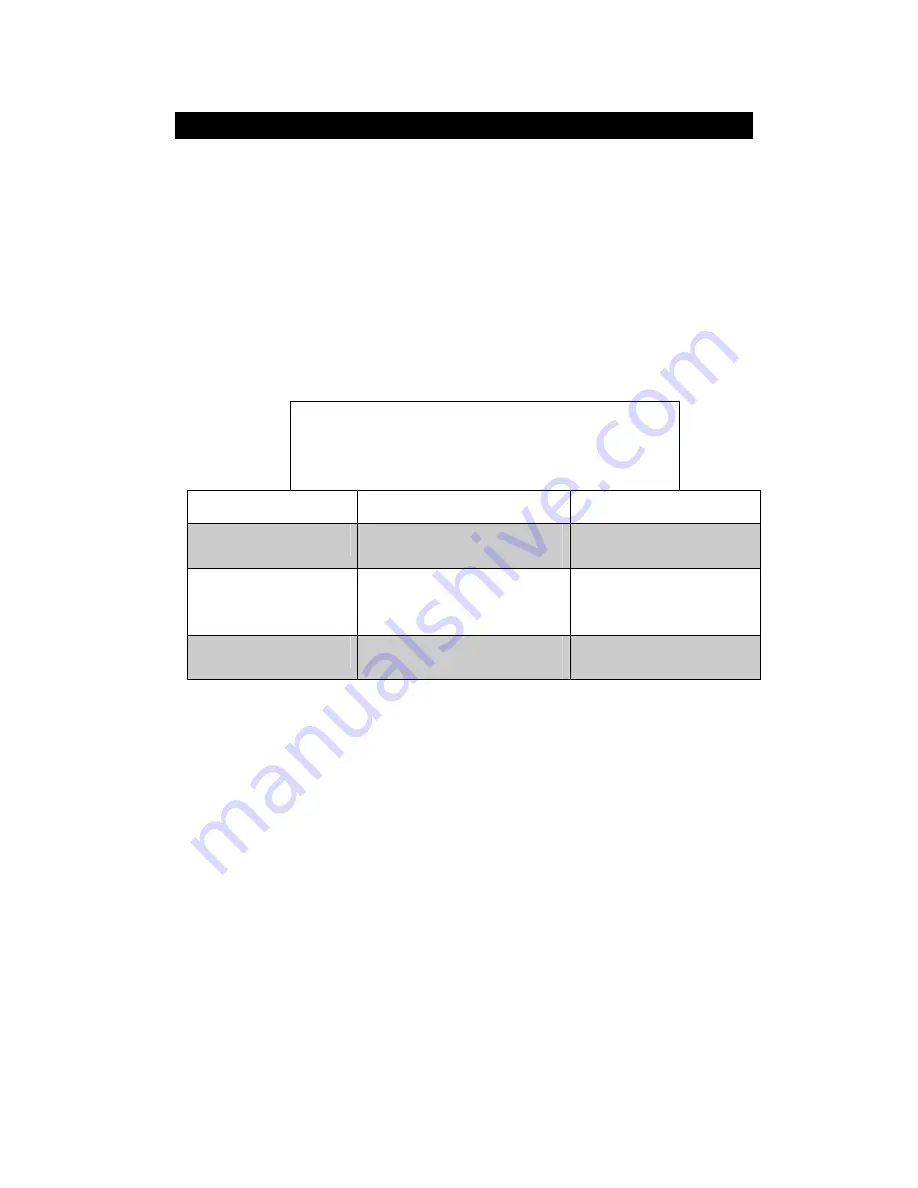

Nozzle diameter (inches)

spray paint

head of Fliter

.011

—

.013

Low Viscosity Varnish or color

paint

100 head

(

red

)

.015

—

.019

Oil and latex paint, exterior wall

coating

60 head

(

white

)

.021

—

.026

High solid content heavy-duty

coatings

30 head

(

green

)

1. seal oil and the protection of the pump body

Spraying in fixed before sealing oil will not only add to the role of sealing equipment,

and better ensure that the cylinder piston rod sealing life, and in long-term storage does not

work, let the body protection equipment inhalation solution is to prevent equipment corrosion

or rust

.