DINO 105T

20

5.

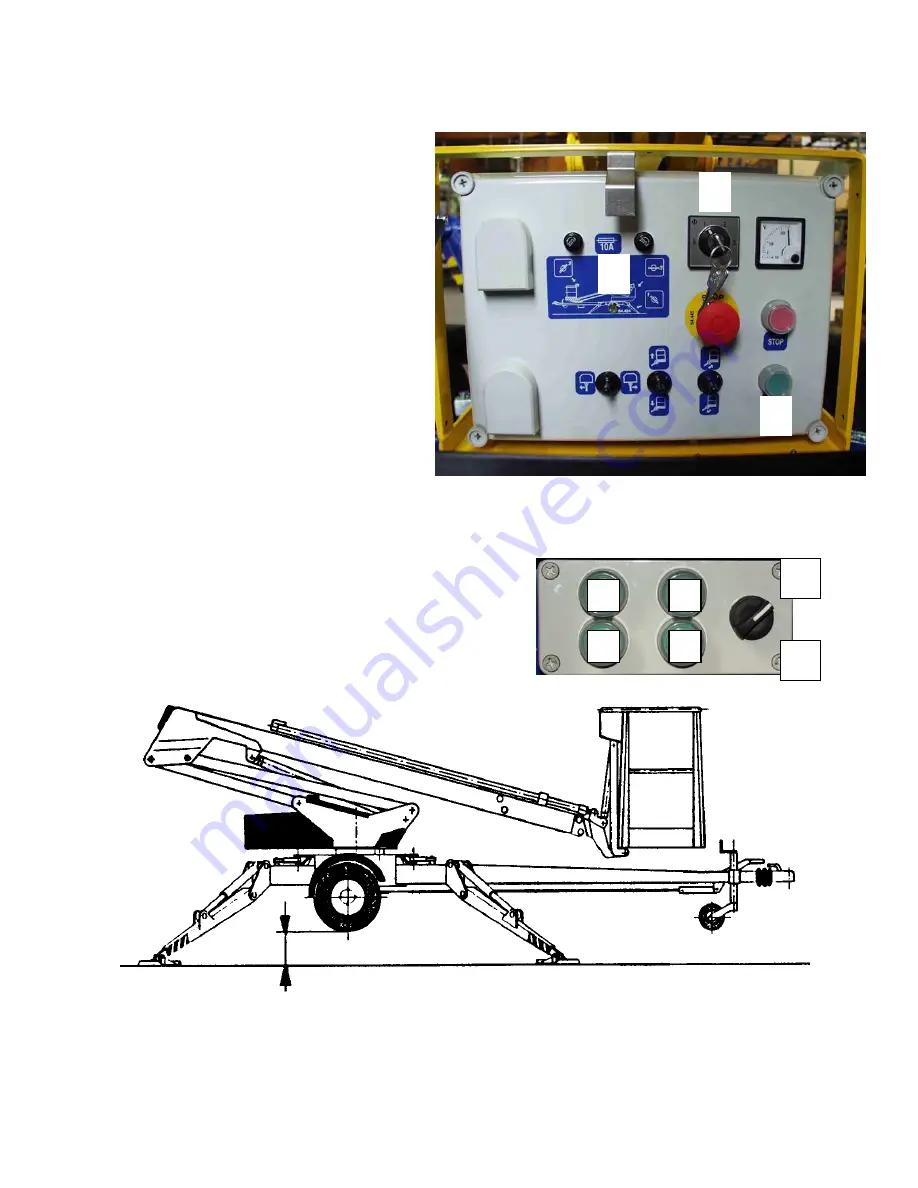

To access the operating controls open the cover on the chassis.

6.

Turn the selector switch (1) to

position 1

7.

Start the engine with button 2 (green).

8.

Lower the front support outriggers (3

and 4, on the towbar side)

9.

Lower the rear support outriggers (1

and 2, do not damage the towbar

jockey wheel)

10.

Level the chassis with the outriggers

with the help of the level indicator.

-

the signal light 4 in the main centre is lit while the

limit switches on the outriggers are closed

-

make sure all outriggers are firmly supported on the

ground

Make sure that the wheels are off the ground.

1

2

3

4

A

B

2

1

4

Summary of Contents for DINO 105T

Page 2: ...DINO 105T 2...

Page 3: ...DINO 105T 3 OPERATING INSTRUCTIONS...

Page 4: ...DINO 105T 4 Valid from serial number 5336...

Page 8: ...DINO 105T 8 REACH DIAGRAM 120 kg...

Page 34: ...DINO 105T 34 LUBRICATION PLAN...

Page 37: ...DINO 105T 37...

Page 69: ...DINO 105T 69 ELECTRIC DIAGRAM 5336...

Page 70: ...DINO 105T 70...

Page 71: ...DINO 105T 71...

Page 72: ...DINO 105T 72...

Page 73: ...DINO 105T 73...

Page 74: ...DINO 105T 74...

Page 75: ...DINO 105T 75 Notes...

Page 77: ...DINO 105T 77 HYDRAULIC DIAGRAM 5336...

Page 78: ...DINO 105T 78 Notes...