55

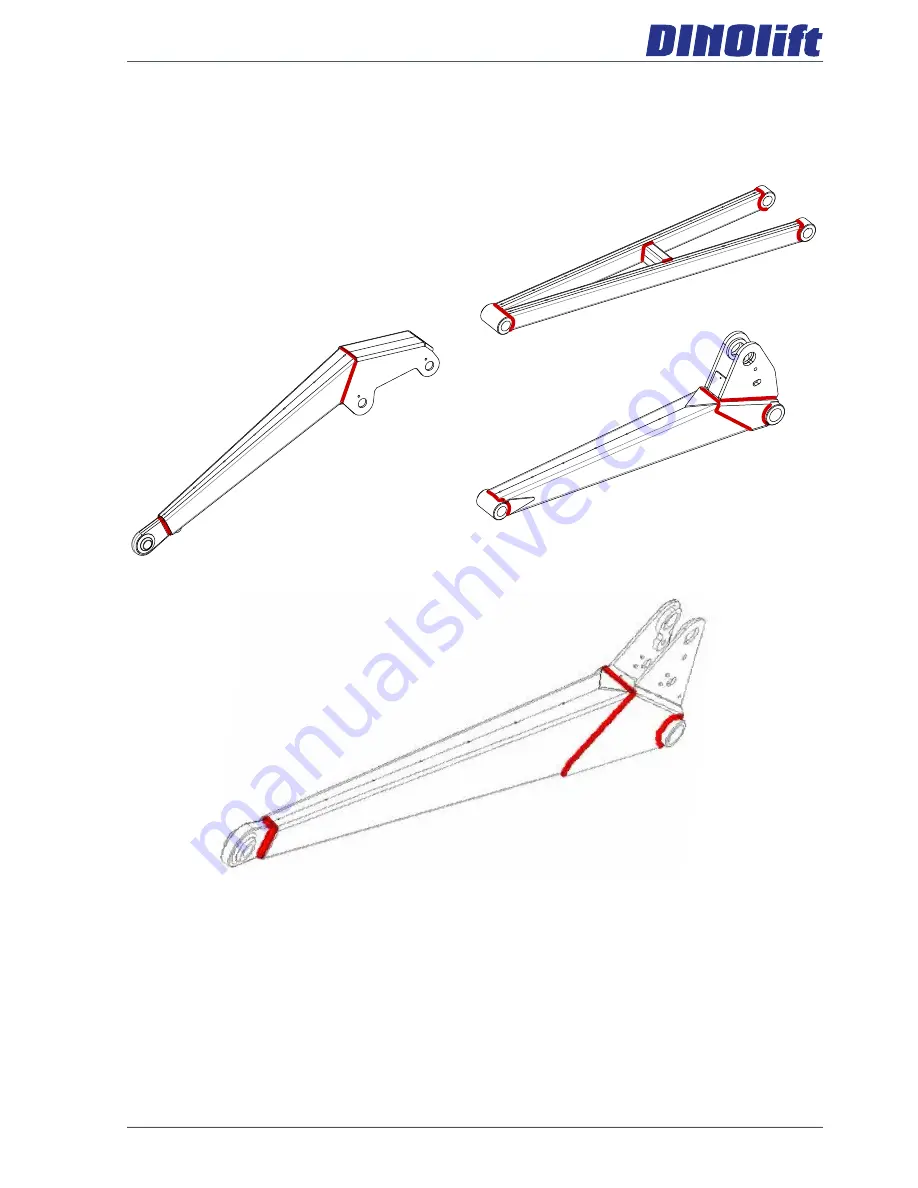

twists, dents, deformations or signs of corrosion. If you observe signs of corrosion,

measure the thickness of the plate.

6.

Inspect the welded seams highlighted in the picture by applying the magnaflux method

160XT

7. Inspect the outrigger cylinder brackets on the central frame side by applying the

magnaflux method

Check:

8. the bearings and play of the outrigger joints

9. the attachment and bearings of the foot plates

10. clean the limit switch mechanisms of the outriggers and check the bushings. Check the

operation.

Summary of Contents for DINO 160XT II

Page 2: ......

Page 19: ...19 6 9 7 11 7 8 1 5 5 3 2 12 3 4 10 13 2 2 LUBRICATION PLAN 14...

Page 79: ...79...

Page 80: ...80 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 81: ...81...

Page 82: ...82 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 83: ...83...

Page 84: ...84 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 85: ...85...

Page 86: ...86 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 87: ...87...

Page 88: ...88 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 89: ...89...

Page 90: ...90 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 91: ...91...

Page 92: ...92 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 93: ...93...

Page 94: ...94 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 95: ...95...

Page 96: ...96 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 97: ...97...

Page 98: ...98 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 99: ...99...

Page 100: ...100 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 101: ...101...

Page 102: ...102 Maintenance instructions DINO 160XT II 180XT II 210XT II...

Page 103: ...103...