2

Introduction

Thank you for buying our product.

In order to get the best performance out of the plant and ensure

the maximum lifespan of its parts, the use and maintenance

instructions contained in this manual must be read and strictly

complied with, as well as

the safety instructions contained

in the relevant folder

. If repairs to the plant are required, we

recommend that our clients contact our service centre work-

shops, as they have the necessary equipment and personnel

that are specifically trained and constantly updated.

All our welding power sources and equipment are constantly

developed and so changes may be made in terms of their con-

struction and features.

Description

MULTI-FUNCTION INVERTER WELDING POWER SOURCE

for MIG-MAG, MMA, and TIG WELDING

The multi-function equipments are characterised by cutting

edge, attractive design combined with latest generation inverter

technology and digital welding control. Innovative, technologi-

cally advanced, robust, and easy to use, they can be used for

very high quality MIG-MAG and Pulse MIG welding for all ma-

terials and especially stainless steel and aluminium, reducing

repeat work due to spray to a minimum, using electrodes, and

in TIG with “Lift” type ignition, and they represent the best so-

lution for all industrial fields and all specialist welding purposes

that call for high precision and repeatable results. These weld-

ing equipments, fitted with an innovative synergic digital control,

colour display, and the extraordinary software

DIX ARC

meet

the needs of those that wish to combine synergy with complete

control of all welding parameters.

They come in a version with a separate feeder (WF 793.M).

These are systems open to the future evolution of technology -

the control software can be kept up to date with the latest ver-

sions with the help of a personal computer.

Operating features

The main feature of the welding unit

DIX PI 3006.M PULS,

DIX PI 4006.M PULS and DIX PI 4606.M PULS

are:

•

Metallic main structure with shockproof plastic front frames.

•

Controls protected by a visor.

•

Spatter free exceptional welding characteristics in both MIG/

MAG, MIG Pulsed and MIG Dual Pulsed on any material and

with any gas.

•

High welding performance in both MMA and TIG by “Lift”

mode striking.

•

Synergic digital control of all welding parameters, displayed

via the innovative colour display, also featuring the follow-

ing functions:

- Allows less expert operators to regulate all welding param-

eters in a user-friendly way and extremely easily, choos-

ing the type of program on the basis of the material, wire

diameter, and gas used.

- Innovative “

DIX ARC

” software for controlling all welding

parameters.

- With the special MIG torches you can adjust the welding

parameters at a distance straight from the torch.

- BURN BACK control. At the end of each weld, in any con-

dition and with any material, the digital control ensures a

perfect wire cut, prevents the typical “wire globule” from

forming and ensures correct arc restriking.

- WSC Wire start control. This arc striking control device pre-

vents wire from sticking to the workpiece or torch nozzle

and ensures precise and smooth arc striking, particularly

when welding aluminium.

- Welding parameters that are controlled digitally by a micro-

processor, are monitored and modified in just a few sec-

onds, maintaining a consistently precise and stable arc as

the welding conditions continue to vary due to the move-

ment of the torch and the irregularities of the parts to be

welded.

Introduction

2

Description

2

Operating features

2

Technical data

3

Usage limits (IEC 60974-1)

3

How to lift up the system

3

Opening the packaging

4

Installation and connections

4

Connection to the electrical supply

4

Usage norms

4

MIG-MAG / PULSE MIG / DOUBLE PULSE MIG

Welding 5

Spot welding

7

Interval welding

7

Aluminium welding

7

Electrode welding (MMA)

7

TIG welding with “Lift”

8

Maintenance

8

Optional

8

The pointing out of any difficulties and their elimination 9

Replacing the digital interface PCB

9

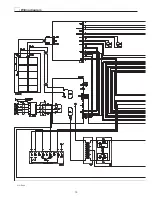

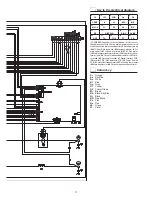

Wiring diagram

10

Key to the electrical diagram

11

Colour key

11

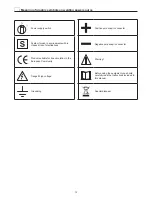

Meaning of graphic symbols on welding power

source 12

Copyright © 2018 DINSE G.m.b.H., Hamburg.

These instructions or excerpts there of shall not be duplicated, transla-

ted or reproduced, nor shall they be stored, processed, transmitted or

distributed by any electronic means without the prior written permission

of DINSE G.m.b.H.

D I N S E G . m . b . H .

Tarpen 36 • D-22419 Hamburg

Tel. +49 (0)40 658 75-0

Fax +49 (0)40 658 75-200

info@dinse.eu – www.dinse.eu

Summary of Contents for DIX PI 3006.M PULS

Page 10: ...10 2101EA86 Wiring diagram ...