22

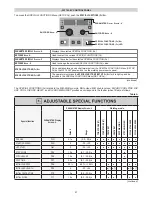

Special function

PARAMETER Display

Screen - A

PARAMETER Display Screen - V

Welding mode

Default

Range

TWO STR

OK

E (2T)

FOU

R STR

OK

E (4T)

CR

ATER

2T

CR

ATER

4T

SPOT WELDIN

G

STITC

H WELDIN

G

CYC

LE ST

AN

DA

RD

CYC

LE A

DV

AN

CED

FINAL SLOPE

F12

1.0s

(0.0 - 20.0)s

●

●

●

●

FINAL CURRENT

F13

-30%

-100% - +50%

●

●

●

●

FINAL ARC LENGTH

F14

0

-30 - +30

● (*) ● (*)

● (*) ● (*)

FINAL CRATER TIME

F15

0.0s

(0.0 - 20.0)s

●

BURN BACK

bub

0

-30 - +30

●

●

●

●

●

●

●

●

POST GAS

PoG

1.0s

(0.0 - 10.0)s

●

●

●

●

●

●

●

●

FIRST SLOPE ( I

1

TO I

2

)

F18

0.05s

(0.00 - 2.00)s

●

CYCLE CURRENT

F19

20%

-99% - +100%

●

●

CYCLE ARC LENGTH

F20

0

-30 - +30

●

●

SECOND SLOPE ( I

2

TO I

1

)

F21

0.05s

(0.00 - 2.00)s

●

FIRST SLOPE ( I

1

TO I

2

)

F22 *

5

(0 - 100)

● (°) ● (°) ● (°) ● (°) ● (°) ● (°) ● (°) ● (°)

DUAL PULSE DELTA CURRENT

F23 *

50%

-100% - +200%

●

●

●

●

●

●

●

●

DUAL PULSE ARC LENGTH

F24 *

0

-30 - +30

● (°) ● (°) ● (°) ● (°) ● (°) ● (°) ● (°) ● (°)

DUAL PULSE BALANCE

F25 *

0%

-40% - +40%

●

●

●

●

●

●

●

●

DUAL PULSE FREQUENCY

F26 *

2.7Hz

(0.1 - 5.0)Hz

●

●

●

●

●

●

●

●

SECOND SLOPE ( I

2

TO I

1

)

F27 *

5

(0 - 100)

● (°) ● (°) ● (°) ● (°) ● (°) ● (°) ● (°) ● (°)

SLOPE JOB

F28

0.5s

(0.1 - 20.0) s

●

●

●

●

●

●

●

●

DYNAMICS

din **

0

-30 - +30

●

●

●

●

●

●

●

●

* Only for the

MIG double pulsed

process.

** Only for the

DIX ARC MEGA FAST

process.

WARNING:

•

The STANDARD or ADVANCED welding CYCLE mode can only be activated by opening the

ADVANCED SETUP Menu

-

AD-

VANCED MODE

-

CYCLE

(for further explanations, see the relevant paragraph).

•

(*) This

SPECIAL FUNCTION

is only to be found if the

ADVANCED CRATER

function has been activated by accessing the

AD-

VANCED SETUP Menu

-

ADVANCED MODE

-

CRATER - ADVANCED

(for further explanations, see the relevant paragraph).

•

(°) These

SPECIAL FUNCTIONS

can only be activated for all the welding machine’s welding modes but going to the

ADVANCED

SETTINGS Menu - ADVANCED MODE - DOUBLE PULSED - ADVANCED

(for further explanations, see the relevant paragraph).

•

It is possible to access editing of the

SPECIAL FUNCTIONS (Fx)

during welding.

•

Some of the values edited will be used immediately by the operator, while others will be active from when the next welding

task begins.

Summary of Contents for DIX PI 3006.M PULS

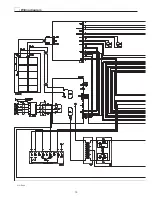

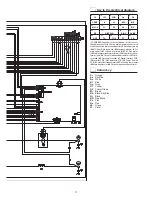

Page 10: ...10 2101EA86 Wiring diagram ...