3

- Exclusive SWS “Smart Welding Stop” system at the end of

TIG welding. Lifting up the torch without switching off the

arc will introduce a slope down and it will switch off auto-

matically.

- “Energy Saving” function to operate the power source cool-

ing fan and the torch water cooling only when necessary.

- Auto-diagnostic feature for trouble shooting.

- Password-controlled total or partial equipment access.

•

High electrical performance resulting in a reduction in ener-

gy consumption.

•

Remote parameter adjustment directly from WF 793.M feed-

er.

Technical data

The general technical data of the system are summarized in

table 1.

Usage limits (IEC 60974-1)

The use of a welder is typically discontinuous, in that it is made

up of effective work periods (welding) and rest periods (for the

positioning of parts, the replacement of wire and underflush-

ing operations etc. This welder is dimensioned to supply a I

2

max nominal current in complete safety for a period of work of

40/50% of the total usage time. The regulations in force estab-

lish the total usage time to be 10 minutes. The work cycle is

considered to be 40/50% of this period of time. Exceeding the

work cycle allowed could cause a trip switch to trip, which pro-

tects the components inside the welding power source against

dangerous overheating. After several minutes the overheat cut-

off rearms automatically and the welder is ready for use again.

How to lift up the system

Strap the system safely and securely in the slings working from

the bottom, then lift up from the ground.

This welding power source has a robust handle built into the

frame for moving the equipment.

NOTE: These hoisting and transportation devices conform to

European standards. Do not use other hoisting and transpor-

tation systems.

Table 1

Model

DIX PI 3006.M PULS

DIX PI 4006.M PULS

DIX PI 4606.M PULS

MIG-MAG welding

Three-phase input 50/60 Hz

V

400 ± 20%

400 ± 20%

400 ± 20%

Mains supply: Z

max

Ω

0,037

0,028

0,017

Input power @ I

2

Max

kVA

18,8

25,5

32

Delayed fuse (I

2

@ 60%)

A

25

30

40

Power factor / cosφ

0,64 / 0,99

0,66 / 0,99

0,66 / 0,99

Efficiency degree

η

0,83

0,86

0,89

Open circuit voltage

V

63

70

70

Current range

A

10 ÷ 330

10 ÷ 400

10÷500

Duty cycle @ 100% (40°C)

A

280

330

380

Duty cycle @ 60% (40°C)

A

300

370

460

Duty cycle @ X% (40°C)

A

330 (40%)

400 (50%)

500 (50%)

Wires diameter (*)

mm

0,6 ÷ 1,2 (*)

0,6 ÷ 1,6 (*)

0,6 ÷ 1,6 (*)

N° rollers (*)

4 (*)

4 (*)

4 (*)

Power output of feeder motor (*)

W

100 (*)

100 (*)

100 (*)

Rated wire feeding speed (*)

m/min

0,5 ÷ 25 (*)

0,5 ÷ 25 (*)

0,5 ÷ 25 (*)

Spool (*)

Diameter

Weight

mm

kg

Ø300 (*)

15 (*)

Ø300 (*)

15 (*)

Ø300 (*)

15 (*)

Standards

IEC 60974-1 - IEC 60974-5 (*) - IEC 60974-10

Protection class

IP 23 S

IP 23 S

IP 23 S

Insulation class

H

H

H

Dimensions

mm

660 - 515 - 290

660 - 515 - 290

660 - 515 - 290

Weight

kg

35

40

44

(*) On the WF 793.M feeder, fitted separately.

WARNING: This equipment complies with EN//IEC 61000-3-12 provided that the maximum permissible system impedance Z

max

is less than or

equal to 0,037 Ω DIX PI 3006.M PULS - 0,028 Ω DIX PI 4006.M PULS - 0,017 Ω DIX PI 4606.M PULS at the interface point between the user’s

supply and the public system. It is the responsibility of the installer or user of the equipment to ensure, by consultation with the distribution net

-

work operator if necessary, that the equipment is connected only to a supply with maximum permissible system impedance Z

max

less than or

equal to 0,037 Ω DIX PI 3006.M PULS - 0,028 Ω DIX PI 4006.M PULS - 0,017 Ω DIX PI 4606.M PULS.

This system, tested according to EN/IEC 61000-3-3, meets the requirements of EN/IEC 61000-3-11.

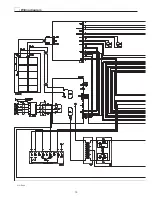

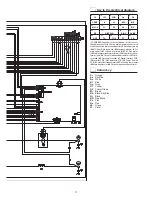

Summary of Contents for DIX PI 3006.M PULS

Page 10: ...10 2101EA86 Wiring diagram ...