5

MIG-MAG / PULSE MIG / DOUBLE

PULSE MIG Welding

To begin MIG-MAG / PULSE MIG / DOUBLE PULSE MIG weld-

ing, carry out the following tasks (with the welding power source

switched off).

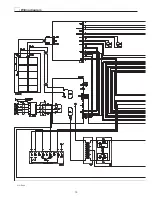

1 - Connecting the gas hose and torch (Fig. B1-B2)

•

Connect the gas hose to the pressure reducer fitted on the

cylinder beforehand.

•

Screw the torch onto the centralised connection on the front

panel of the feeder and connect the feed (blue) and return

(red) water hoses for cooling the torch to the respective (blue

and red) rapid couplings on the front panel of the feeder.

2A - Connecting the cables - Welding with a HAND

HELD TORCH SET as POSITIVE POLE (Fig. B1)

1) The feeder - welding power source connecting cable is

used to connect the welding power source to the feeder.

WARNING: Do not disconnect the wire-feeder until the

welding power source has been switched off.

Connect up the interconnection cables (power cable, an-

cillary wiring and gas tube) to the special attachments and

couplings shown in Fig. B1.

The delivery (blue coloured) and return (red coloured) wa-

ter tubes, used for cooling the torch of the welding power

source, are part of the interconnection cable and should

be connected as follows:

FIG. A

FIG. B1

2000FC15

Summary of Contents for DIX PI 3006.M PULS

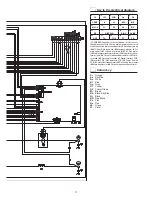

Page 10: ...10 2101EA86 Wiring diagram ...