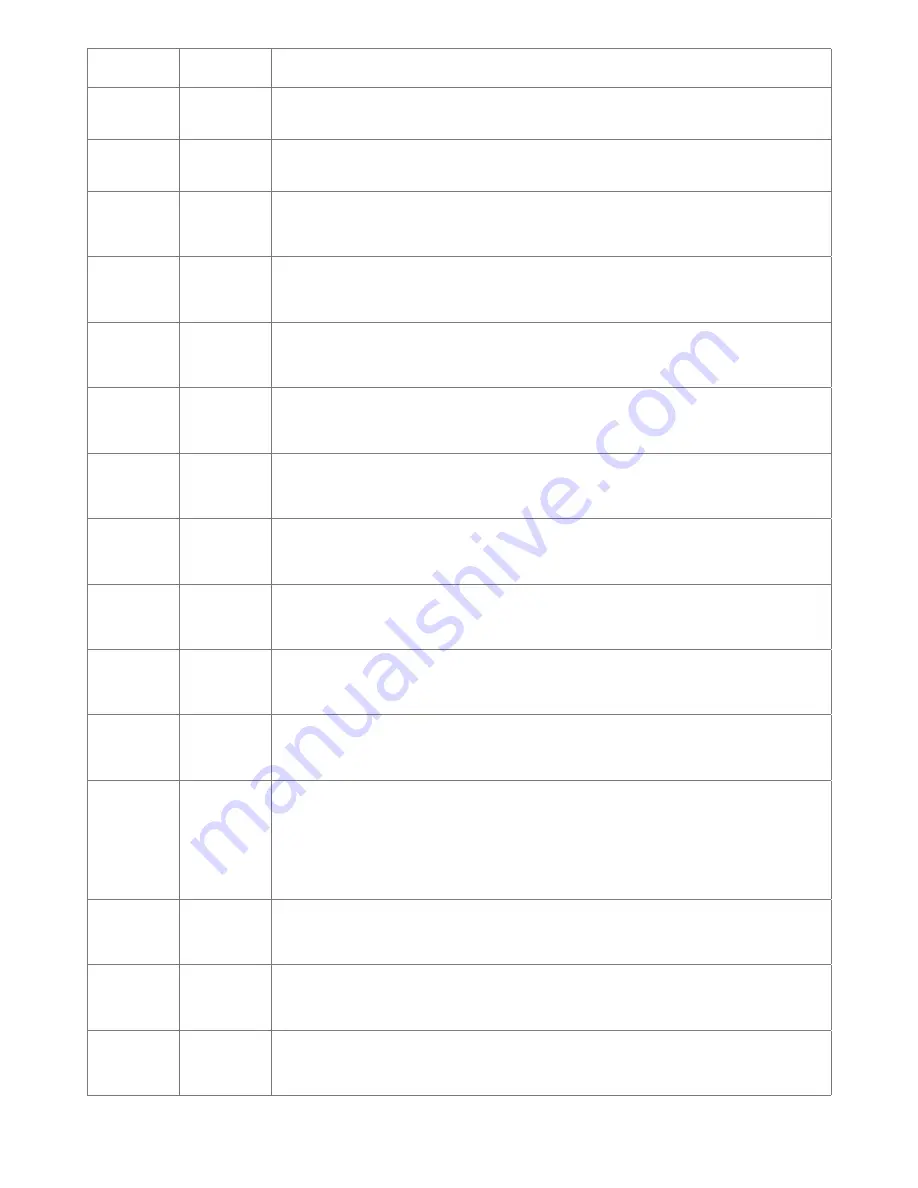

58

Error

condition

Error code

Error description and possible diagnosis

Err

T°C

THERMAL PROTECTION

The welding stops due to an excessively high temperature (thermostat activated).

Automatic reset error.

Err

H20

COOLER PRESSURE

The fluid in the cooling system is at low pressure.

NON automatic reset error.

Err

E1.0

CONFIG. FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E1.1

USER FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E1.2

TORCH FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E1.3

CALIBRATION FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E1.6

MMA DEFAULTS MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E1.7

TIG DEFAULTS MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E1.8

MIG DEFAULTS MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E1.9

WELDER DEFAULTS MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E2.0

FILE SYSTEM ERROR

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E3.2

STICKING

This error is displayed when a short-circuit has been formed between the machine’s output

terminals for more than 1.2 seconds.

NON automatic reset error.

To remove the error state, eliminate the short circuit so that the voltage on the torch goes above the

threshold value again. At this stage the error condition disappears and the welding machine goes

back to the mode prior to the sticking. If the torch trigger is still pushed, it must be released and

pressed again to begin welding again.

Err

E3.3

MOTOR SPEED FAULT

NON automatic reset error.

Check that the rollers on the wire feeder mechanism are not stuck and that the welding wire comes

out correctly, otherwise

contact Technical Assistance Department immediately

.

Err

E4.0

LAST SETUP NOT VALID

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E4.1

JOBS WRONG

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

(continued)

Summary of Contents for DIX PI 3006.M PULS

Page 10: ...10 2101EA86 Wiring diagram ...