59

Error

condition

Error code

Error description and possible diagnosis

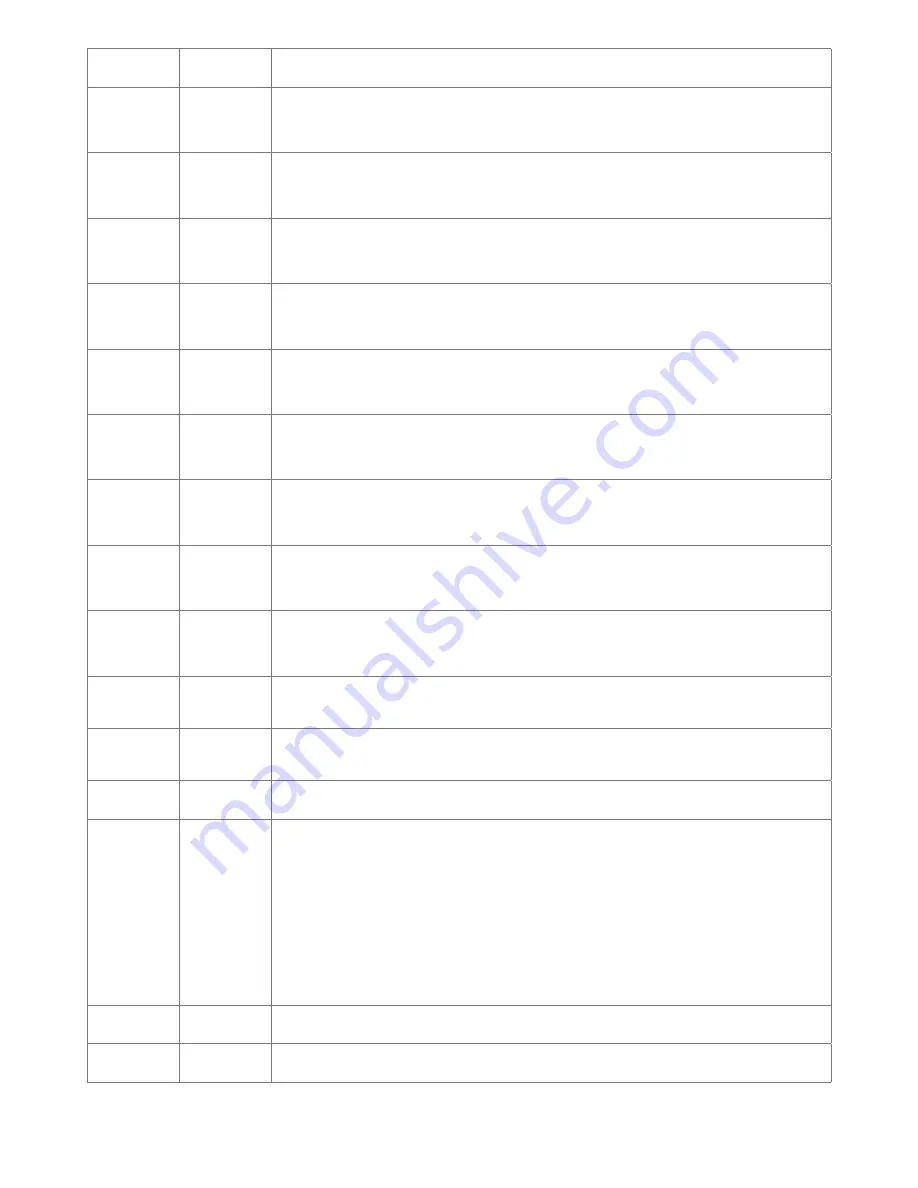

Err

E4.2

MIG SYN SPECIAL FUNCTION (Fx) WRONG

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E4.3

MIG MAN SPECIAL FUNCTION (Fx) WRONG

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E4.4

SPECIAL PULSED MIG FUNCTIONS (Fx) NOT VALID

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E4.5

SPECIAL DOUBLE PULSED MIG FUNCTIONS (Fx) NOT VALID

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E5.0

MIG PROGRAMS MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E5.1

PULSED MIG WELDING PROGRAMMES MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E5.3

MMA PROGRAMS MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E5.4

TIG PROGRAMS MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E5.5

MIG MANUAL PROGRAMS MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Error visible on

DISPLAY

ONLY in the event of a fault and NOT in the

ERROR LOG Menu

.

Err

E6.0

WF 793.M CAN LINK MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Err

E6.1

ROBOT LINK MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

Err

E6.5

NO ROBOT INTERFACE

Automatic reset error.

Err

E7.0

RC ANALOGIC MISSING

NON automatic reset error.

Check that the ANALOGIC RC - OBLIGATORY function is included within the

ADVANCED SETUP

Menu / EQUIPMENT LAYOUT

.

After this initial check you need to know that this error can

only

occur in the following cases:

•

ANALOGIC RC remote control not connected to the relevant connector.

•

The welding plant does not recognise the ANALOGIC RC remote control, even though it is

connected correctly.

•

The ANALOGIC RC remote control disconnected when the welding plant is working normally.

As soon as the remote control is connected again this error condition

resets itself automatically!

If the alarm occurs even when the ANALOGIC RC - OPTIONAL function is included in the

ADVANCED SETUP Menu / EQUIPMENT LAYOUT

,

call Technical Assistance Department

immediately.

Err

E8.3

NO GAS FLOW

Error reset by a command from the robot’s board (see robot interface manual).

Err

E8.4

NO H2O FLOW

Error reset by a command from the robot’s board (see robot interface manual).

(continued)

Summary of Contents for DIX PI 3006.M PULS

Page 10: ...10 2101EA86 Wiring diagram ...