8

1,2 ÷ 2

1,5 ÷ 3

3 ÷ 5

5 ÷ 12

≥ 12

≥ 20

1,6

2

2,5

3,25

4

≥ 5

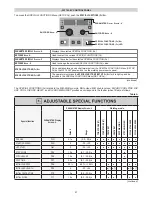

Table 4

Ø electrode (mm)

Current (A)

1,6

2

2,5

3,25

4

5

6

30 ÷ 60

40 ÷ 75

60 ÷ 110

95 ÷ 140

140 ÷ 190

190 ÷ 240

220 ÷ 330

The current to be used depends on the welding positions and

the type of joint, and it increases according to the thickness and

dimensions of the part.

The current intensity to be used for the different types of weld-

ing, within the field of regulation shown in table 4 is:

•

High for plane, frontal plane and vertical upwards welding.

•

Medium for overhead welding.

•

Low for vertical downwards welding and for joining small pre-

heated pieces.

A fairly approximate indication of the average current to use in

the welding of electrodes for ordinary steel is given by the fol-

lowing formula:

I = 50 × (Øe - 1)

Where:

I = intensity of the welding current

Øe = electrode diameter

Example:

For electrode diameter 4 mm

I = 50 × (4 - 1) = 50 × 3 = 150A

TIG welding with “Lift”

This type of ignition is commonly used where high frequency

igniters are not permitted, e.g. Hospitals and nuclear power

plants. The “Lift” type ignition makes it possible to reduce tung-

sten inclusions on ignition to a minimum. The molten bath and

the electrode are protected by and inert gas (for example, Ar-

gon). This type of welding is used to weld thin sheet metal or

when elevated quality is required.

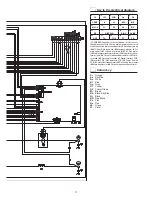

1) Connecting the welding cables (Fig. E):

•

Connect one end of the gas hose to the gas connecter on

the TIG torch and the other end to the pressure reducer

on the inert gas cylinder (Argon or similar).

•

With the welding power source switched off:

- Connect the ground cable to the snap-on connector

(positive).

- Connect the relative ground clamp to the workpiece or

to the workpiece support in an area free of rust, paint,

grease, etc..

- Connect the TIG torch power cable to the snap-on con-

nector marked - (negative).

2) Switch the welding power source on by moving the power

supply switch to

I

(Pos. 3, Fig. A).

3) Make the adjustments and do the parameter settings on

the control panel.

4) Open the gas cylinder and regulate the flow by adjusting

the valve on the TIG torch by hand.

5) Ignite the electric arc by contact, using a decisive, quick

movement without dragging the tungsten electrode on the

piece to be welded (“Lift” type ignition).

6) The welder has a SWS “Smart Welding Stop” system for

the end of TIG welding. Lifting up the torch without switch-

ing off the arc will introduce a slope down and it will switch

off automatically.

7) When you have finished welding remember to shut the

valve on the gas cylinder.

Table 5 shows the currents to use with the respective elec-

trodes for TIG DC welding. This input is not absolute but is for

your guidance only; read the electrode manufacturers’ instruc-

tions for a specific choice. The diameter of the electrode to use

is directly proportional to the current being used for welding.

Table 5

Ø ELECTRODE

(mm)

ELECTRODE TYPE

Current adjustment field (A)

TIG DC

Tungsten

Ce 1%

Grey

Tungsten

Rare ground 2%

Turchoise

1

10-50

10-50

1,6

50-80

50-80

2,4

80-150

80-150

3,2

150-250

150-250

4

200-400

200-400

Maintenance

ATTENTION: Cut off the power supply to the equipment be-

fore effecting any internal inspection.

DIX PI 3006.M PULS, DIX PI 4006.M PULS and

DIX PI 4606.M PULS

IMPORTANT: For fully electronic welding power sources, re-

moving the dust by sucking it into the welding power source by

the fans, is of utmost importance.

In order to achieve correct functioning of the welding power

source, proceed as described:

•

Periodic removal of accumulations of dirt and dust inside the

equipment using compressed air. Do not point the jet of air

directly at the electrical parts as this could damage them.

•

Periodical inspection for worn cables or loose connections

that could cause overheating.

TORCH

The torch is subjected to high temperatures and is also stressed

by traction and torsion. We recommend not to twist the wire and

not to use the torch to pull the welder. As a result of the above

the torch will require frequent maintenance such as:

•

Cleaning welding splashes from the gas diffuser so that the

gas flows freely.

•

Substitution of the contact point when the hole is deformed.

•

Cleaning of the wire guide liner using trichloroethylene or

specific solvents.

•

Check of the insulation and connections of the power cable;

the connections must be in good electrical and mechanical

condition.

SPARE PARTS

Original spares have been specifically designed for our equip-

ment. The use of spares that are not original may cause vari-

ations in the performance and reduce the safety level of the

equipment. We are not liable for damage due to use of spare

parts that are not original.

Optional

NOTE: The digital control unit of the welding power source is

fitted with a control recognition device which allows it to identify

which device is connected and take action accordingly.

REMOTE CONTROL ANALOGIC RC

This command (that must be plugged into the relevant connec-

tor on the front panel of the WF 793.M drawing unit):

•

Completely replaces the ENCODER - A knob on the WF

793.M feeder’s front panel.

Summary of Contents for DIX PI 3006.M PULS

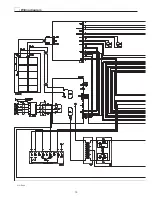

Page 10: ...10 2101EA86 Wiring diagram ...