9

•

Partially (depending on the welding process selected) re-

places the ENCODER - V knob on the WF 793.M feeder’s

front panel.

AIR AND/OR WATER COOLED UP/DOWN TORCH

This command (that must be plugged into the relevant connec-

tor on the front panel of the WF 793.M drawing unit) works as

an alternative to:

•

The ENCODER - A knob on the WF 793.M feeder’s front

panel. In “synergic” MIG MAG and “manual” MIG MAG weld-

ing processes, by pressing the two right (+) and left (-) but-

tons you can regulate the values for the synergic welding

parameters.

•

The ENCODER - V knob on the WF 793.M feeder’s front

panel. In the JOB welding process, by pressing the two right

(+) and left (-) buttons you can scroll the welding points set

previously.

The pointing out of any difficulties

and their elimination

The supply line is attributed with the cause of the most com-

mon difficulties. In the case of breakdown, proceed as follows:

1) Check the value of the supply voltage.

2) Check that the power cable is perfectly connected to the

plug and the supply switch.

3) Check that the power fuses are not burned out or loose.

4) Check whether the following are defective:

•

The switch that supplies the welding power source

•

The plug socket in the wall

•

The welding power source switch

NOTE: Given the required technical skills necessary for the

repair of the welding power source, in case of breakdown we

advise you to contact skilled personnel or our technical ser-

vice department.

Replacing the digital interface PCB

Proceed as follows:

•

Unscrew the 4 screws fastening the front rack panel.

•

Remove both the adjustment knobs.

•

Extract wiring connectors from the digital interface PCB.

•

Unscrew the nuts and washers on the support.

•

Remove the digital interface PCB by lifting it out of its sup-

ports.

•

Proceed vice versa to assemble the new digital interface

PCB.

Summary of Contents for DIX PI 3006.M PULS

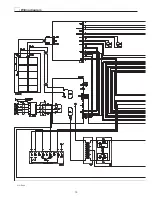

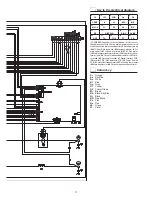

Page 10: ...10 2101EA86 Wiring diagram ...