1 3

D I R E C T H E A L T H C A R E S E R V I C E S . C O . U K

S E R V I C E M A N U A L

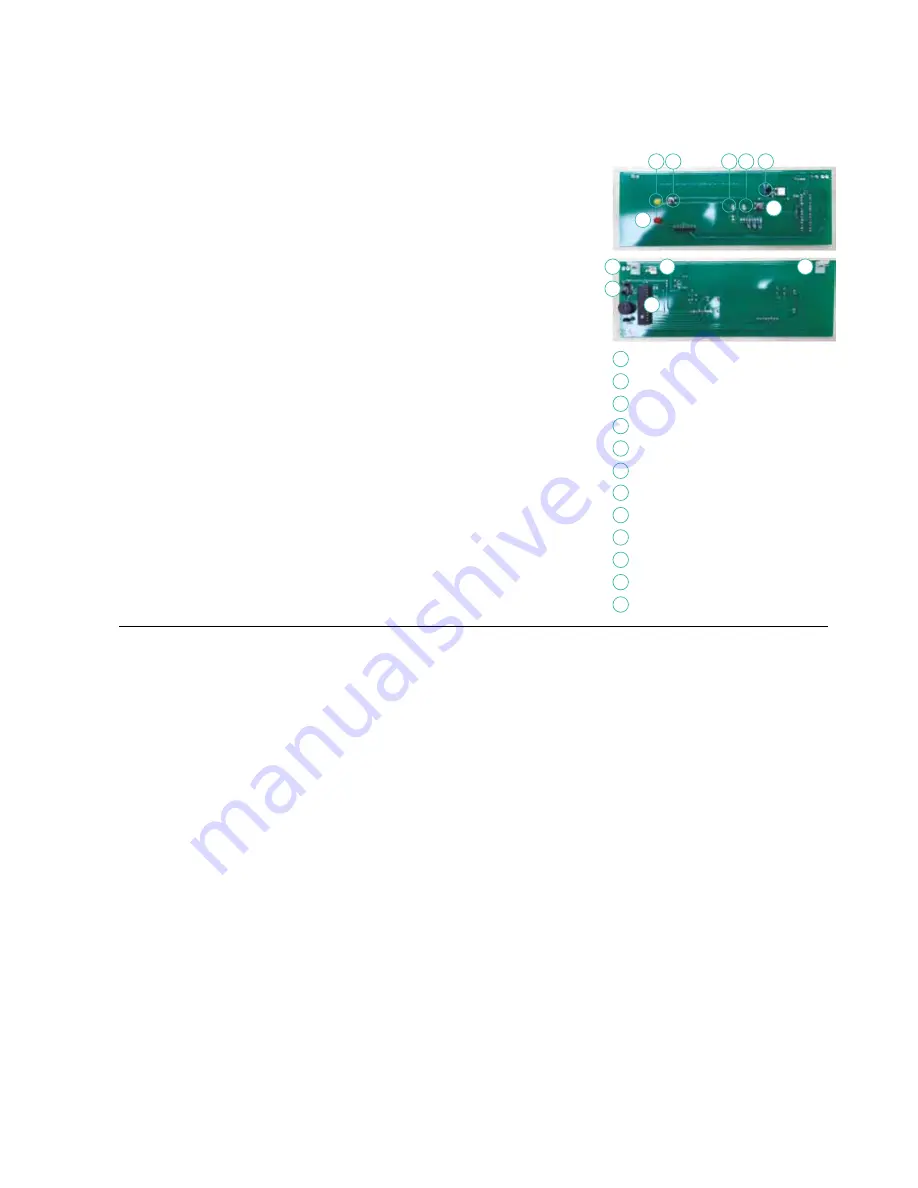

8.9.6 Testing the Control PCB

1. Connect a 5v DC supply to the DC inlet.

2. Connect 240v supply to AC inlet. and compressor to Pump Outlet.

3. LEDs will light up and flash whilst buzzer beeps and compressor will run

4. Connect pressure tube to lower port of the pressure transducer. Once pressure hits

18mmHg then the pump will stop and only the Lo LED will show.

5. Release the pressure and the pump will restart.

6. If the pressure is below 10mmHg then the pressure mode can not be changed.

7. Apply pressure to transducer. Press the Pressure switch and the Hi LED should light up.

8. When pressure reaches 28mmHg then pump will stop.

9. Apply pressure of over 80mmHg to transducer and the High pressure Audible Warning

should sound. This is a fast beeping with the red Pressure Audible Warning LED flashing.

11. Release all pressure and after 90 secs the low pressure Audible Warning will

be activated. This is a slow beep with the red flashing LED.

A list of spares and part numbers are available on request from

Direct Healthcare Services

8

10

9

Mute LED

Mute Switch

Pressure Audible Warning LED

Lo LED

Hi LED

Triac (pump switch)

Pressure Switch

Pressure Transducer

5v DC Inlet

240v Inlet

Microprocessor

240v AC Pump Outlet

1

7

2

8

3

9

4

10

5

11

6

12

12

7

3

1

4

2

5 6

11

9. Technical data

9.1. Power Unit (Pump)

Serial Number ............................As per label on rear of pump

Electrical Supply. ...................................220-240 volt, 50 Hz

Power Consumption ...............................................10 watts

Fuses ................................................................TA1H 250V

Protection against shock ...........................................Class 2

Noise Level ...............................................Approx. 30 dB (A)

Dimensions ...........................................235 x 180 x 80 mm

Weight...................................................................... 1.7 kg

Service Interval....................................................12 months

Expected life ............................................................5 years

Shelf life of parts ......................................................5 years

9.2 Mattress

Serial Number .....................Label on inside of mattress cover

Number of Air Cells ................14 Air Cells / 1 Static Foam Cell

Dimensions ........................ 880 x 1980 x 150 mm (Nominal)

Weight.....................................................................13.4kg

Expected life of Mattress ...........................................5 years

Shelf life of Mattress parts .........................................5 years

10. Optimum conditions

(Applies to Mattress and Pump)

10.1 Environment conditions for transport,

storage and use

Transport .................................................... -5˚C – +40˚C

Storage ........................................................5˚C – +40˚C

Usage ........................................................15˚C – +40˚C

Humidity .......................................................... 10% – 93%

Atmospheric Pressure ........................... 700hPa – 1060hPa

Operational Altitude .............................................. ≤ 2000m

10.2 Exposure

Exposure to direct sunlight, dust, lint and general debris is not

considered to be an issue with the Mercury Advance System.