17

Maintenance

To prevent serious injury from accidental starting turn the

power switch on the engine to its “OFF” position.

To eliminate pressure discharge the spray gun by pressing the

trigger then moving it into the locked position. Wait for the

engine to cool before performing any maintenance procedure.

• DO NOT insert any objects through cooling slots.

• Use a soft bristle brush to loosen caked on dirt, oil, etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

Intake Screen

Examine the screen on the pump’s water inlet. Clean it if the

screen is clogged or replace it if screen is damaged.

Check High Pressure Hose

High pressure hoses can develop leaks from wear and kinking.

Inspect hoses each time before use. Never repair the high

pressure hose. Replace the hose immediately with a suitable hose

that meets or exceeds the original rating.

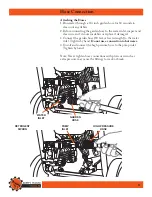

Changing /Cleaning the Air Filter

1. Loosen wing nut and remove cover. Carefully remove filter

assembly. Remove foam filter. Clean cartridge by gently tapping

on a flat surface. Reinstall the foam filter, then reinstall clean or

new cartridge assembly. Install cover and tighten wing nut.

Detergent Siphoning Tube

Examine the filter on the detergent tube and clean if clogged.

The tube should fit tightly on the barbed fitting. Replace the

filter or tube if damaged.

Spray Gun

Examine the hose connection to the spray gun and make sure

it is secure. Test by pressing the trigger, if it “springs back” into

place when you release it, replace the spray gun immediately.

Nozzles

A pulsing sensation felt while squeezing the spray gun trigger

indicates excessive pump pressure caused by a clogged nozzle.

Clean the nozzle with a paper clip or stick pin to free debris.

Spray Wand

Remove nozzle from the wand. Remove the wand from the spray

gun assembly and flush with a garden hose for 30 - 60 seconds.

Reinstall wand onto the spray gun and test with nozzle attached.

!

WARNING

Summary of Contents for 101087

Page 22: ...22 Notes...

Page 23: ...23 Notes...